NiFeP bifunctional transition metal phosphide catalyst as well as preparation and use thereof

A transition metal and phosphide technology, applied in the field of electrochemistry, can solve the problems that the efficiency of catalytic electrolysis of water cannot meet the needs of economic development, and achieve the effects of excellent full hydrolysis catalytic performance, abundant reserves, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 222 mg of ammonium fluoride and 290 mg of Ni (NO 3 ) 2 ·6H 2 O, 278mg FeSO 4 ·7H 2 O and 600 mg of urea were successively added to 40 ml of deionized water, and stirred for half an hour to make the solution evenly mixed.

[0036] The nickel foam (NF) was ultrasonically cleaned with acetone, alcohol solvent, and deionized water in sequence for 30 min, then ultrasonicated with 0.1 M dilute hydrochloric acid for 10-20 min, and finally ultrasonically cleaned with deionized water for 30 min.

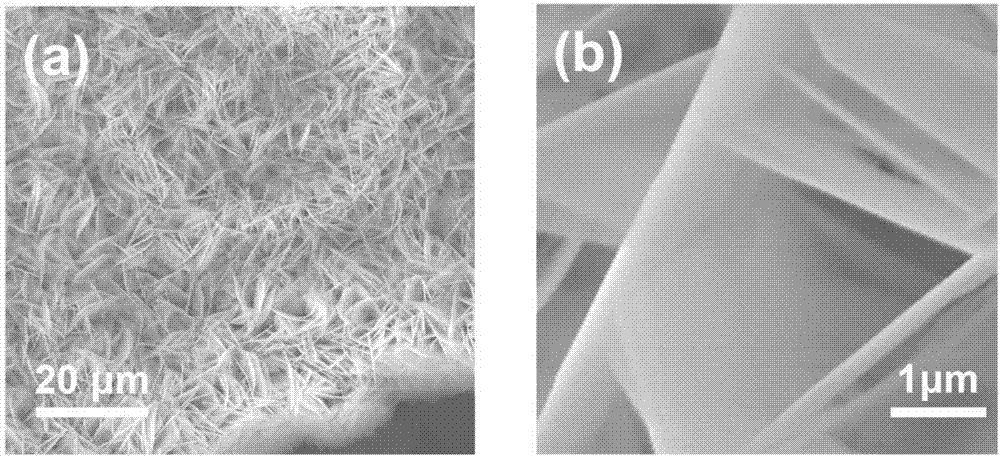

[0037] Put the above-mentioned cleaned substrate into the PTFE liner in a 50ml reaction kettle, pour the above-mentioned mixed solution with uniform stirring, seal the reaction kettle, and then place it in a blast oven for 6 hours at 100°C. NiFe-LDH nanosheets are grown on the substrate.

[0038] After the temperature of the reaction kettle dropped to room temperature, the substrate was taken out and washed with deionized water and absolute ethanol in turn. The purpose of d...

Embodiment 2

[0046] Weigh 222 mg of ammonium fluoride and 290 mg of Ni (NO 3 ) 2 ·6H 2 O, 278mg FeSO 4 ·7H 2 O and 600 mg of urea were successively added to 40 ml of deionized water, and stirred for half an hour to make the solution evenly mixed.

[0047] The carbon fibers (CF) were ultrasonically cleaned with acetone, alcohol solvent, and deionized water for 30 min in turn, then ultrasonicated with 0.1 M dilute hydrochloric acid for 10-20 min, and finally ultrasonically cleaned with deionized water for 30 min.

[0048] Other operations are the same as in Example 1.

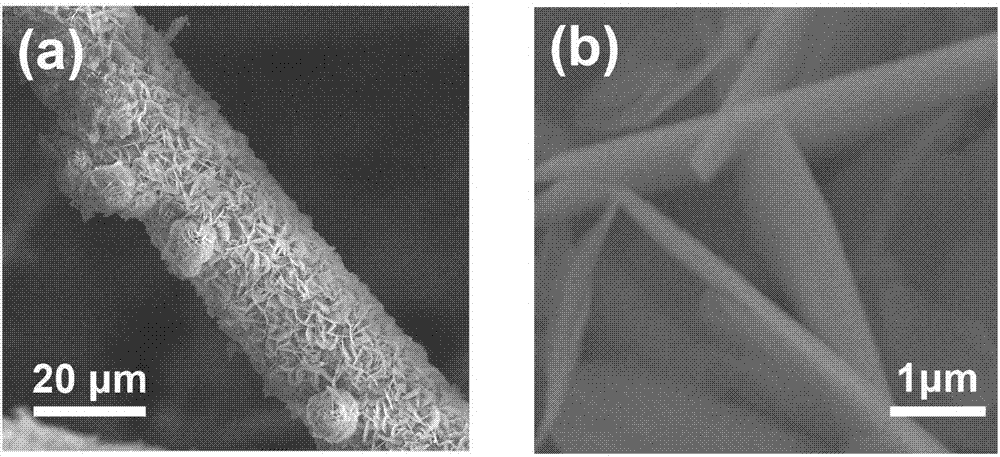

[0049] After growing NiFe-LDH nanosheets on the substrate, the sample with carbon fiber (CF) as the substrate was observed by scanning electron microscope (S-4800). figure 2 As shown, the substrate is covered with uniformly distributed nanosheets up to 5 μm in length.

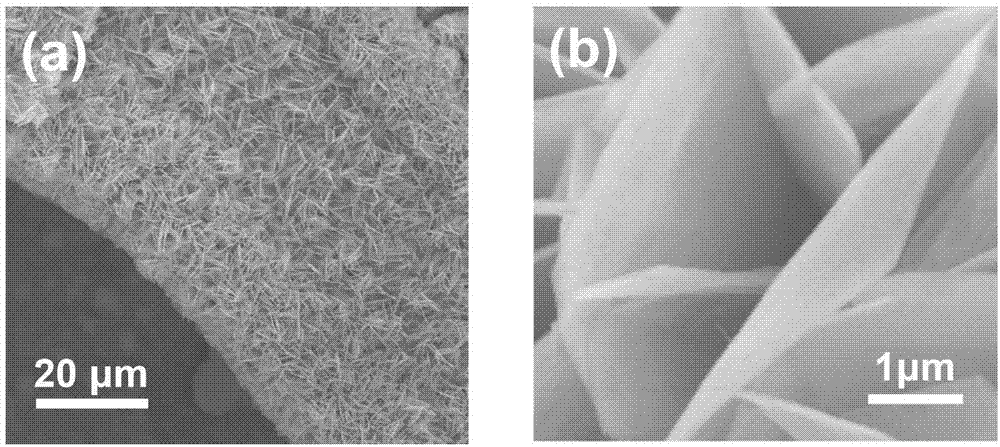

[0050] The morphology of NiFeP@CF after phosphating was observed by scanning electron microscope. Figure 4 As shown, the substrate is covered with un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com