Processing device for automobile exhaust three-way catalyst

A three-way catalyst and automobile catalyst technology, which is applied in the field of automobile exhaust purification, can solve the problems of uneven slurry adhesion and unsatisfactory catalyst purification effect, and achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

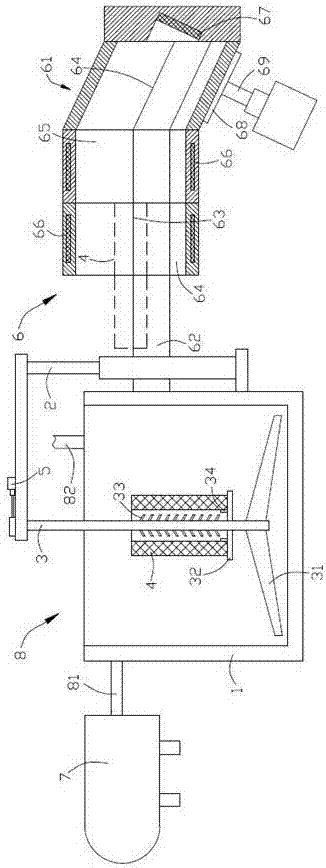

[0016] Combine below figure 1 The present invention is described in detail, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

[0017] The processing equipment of the automobile exhaust three-way catalyst includes a ball mill 7 and a slurry tank 1. After the ball mill 7 ball-mills the raw materials of the automobile catalyst, the powder after ball milling is transported to the slurry tank and stirred with deionized water to form a slurry , and then through the slurry processing device 8, the automobile catalyst carrier is extended into the slurry for coating, and then the coated carrier is transported to the roasting device 9 for roasting; thus, the automatic production of the catalyst can be realized, and the production efficiency can be greatly improved. In the implementation process, one side of the slurry tank 1 is provided with a material delivery pipe 81 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com