Preparation method for double-functionalized KIT-6/ZSM-5 for adsorbing carbon dioxide in smoke

A technology of carbon dioxide and KIT-6, applied in the field of materials, can solve the problems of no research reports and achieve the effects of less environmental pollution, low production cost, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the preparation of KIT-6 / ZSM-5 composite molecular sieve

[0023] Mix 16.87ml H 2 O and 4.54g tetrapropylammonium hydroxide (TPAOH), stirred at room temperature and 350r / min for 0.5h, added 0.167g aluminum isopropoxide and stirred evenly. Then 13.6ml tetraethyl orthosilicate (TEOS) was gradually added into the solution, vigorously stirred at 35°C and 450r / min for 2h, then aged in an autoclave at 150°C for 10h, cooled to room temperature, and the S 1 . Dissolve 4 g of P123 in 125 ml of H 2 O and 6.36ml of HCl, stirred at 35°C and 350r / min for 2h, then added 4.95ml of n-butanol (BuOH), continued to stir for 1h, and recorded the mixed solution as S 2 . Will S 1 Evenly added dropwise to S 2 In order to prepare a gel with a certain molar composition, the final gel molar composition is TEOS:P123:BuOH:HCl:Al:H 2 O=1:0.017:1.31:1.83:0.02:195:0.138. The gel was continuously stirred at 40°C and 450r / min for 24h, then transferred to the reactor, heated at 10...

Embodiment 2

[0024] Example 2: Preparation of KIT-6 / ZSM-5 grafted with triaminosilane coupling agent

[0025] Add 1 g of the KIT-6 / ZSM-5 composite molecular sieve obtained in Example 1 into a round-bottomed flask equipped with 60 ml of toluene and mix well, then add 1 ml of triaminosilane with a density close to 1.0 g / ml with a pipette gun The above mixed sample was heated and condensed to reflux for 12 hours, vacuum filtered and washed repeatedly with absolute ethanol. Finally, the slurry obtained after suction filtration was dried in an oven at 100° C. for 12 hours to obtain KIT-6 / ZSM-5 grafted with a triaminosilane coupling agent.

Embodiment 3

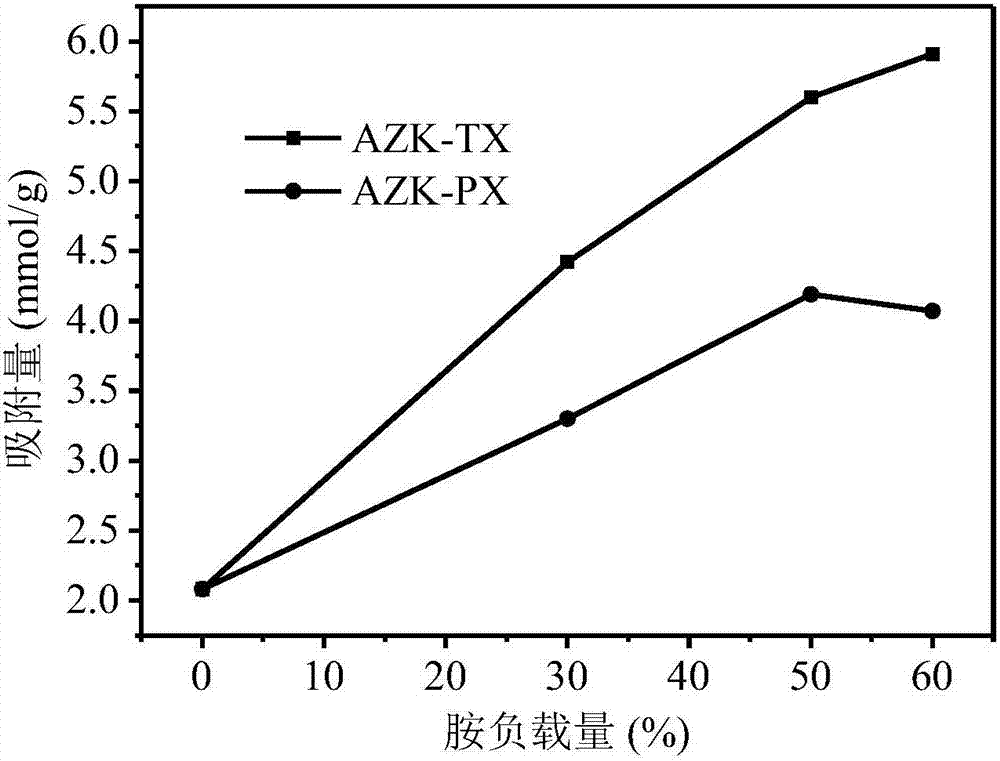

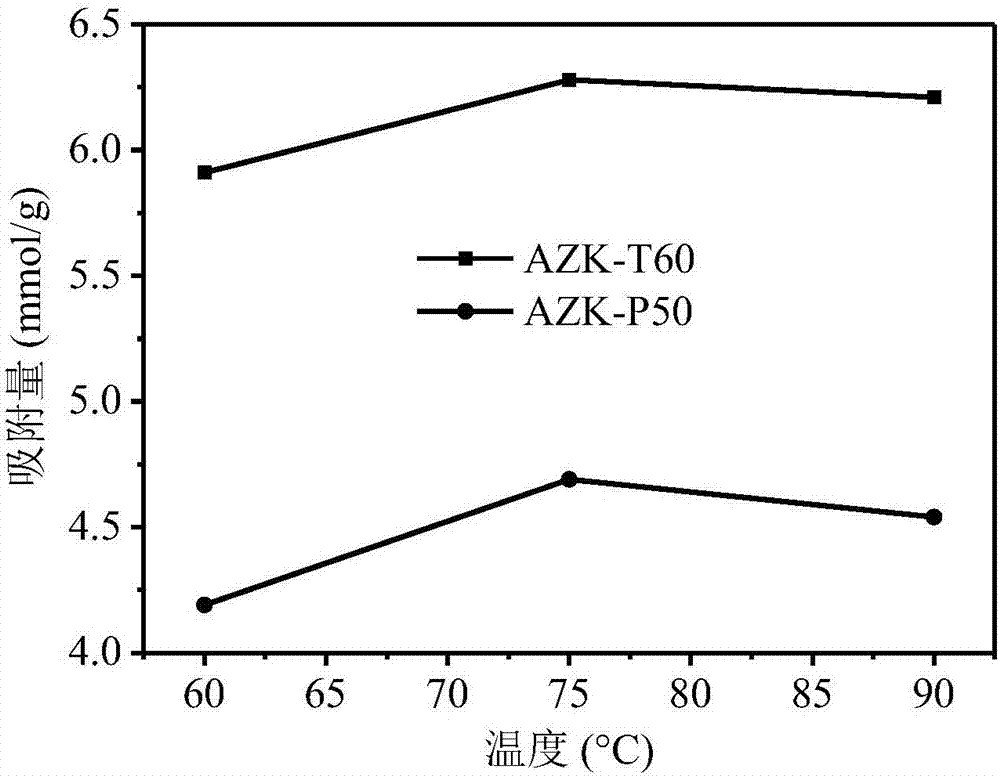

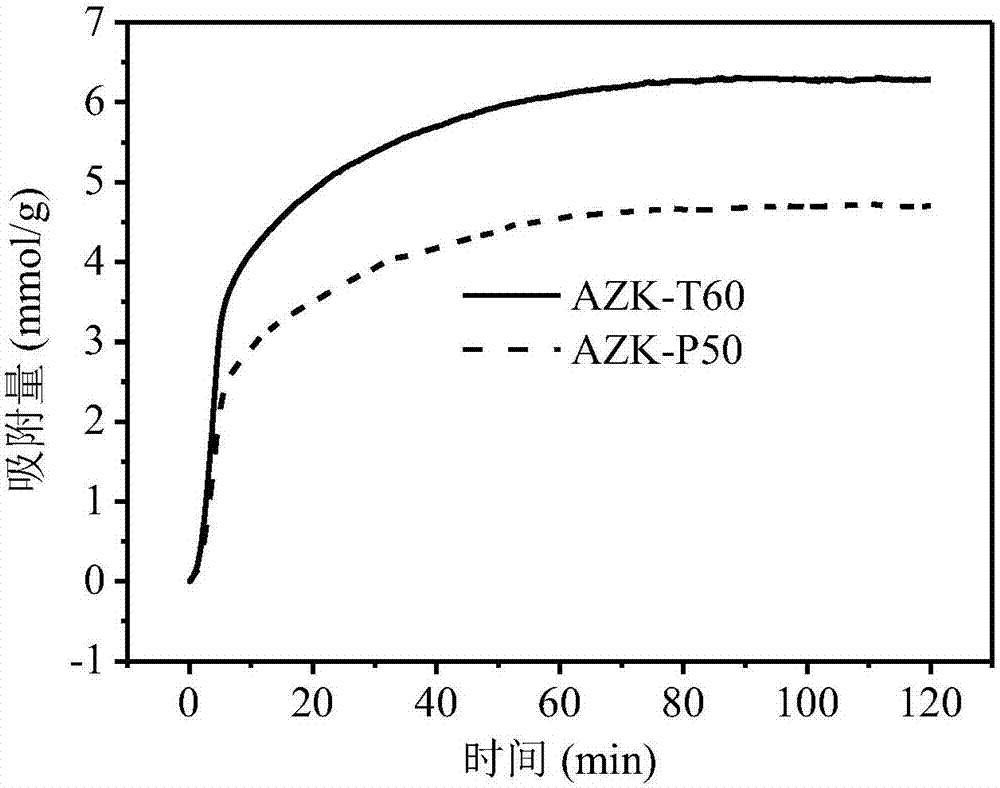

[0026] Example 3: Preparation of bifunctional KIT-6 / ZSM-5

[0027] Add 700 mg of the KIT-6 / ZSM-5 grafted with the triaminosilane coupling agent obtained in Example 2 into a conical flask filled with 25 ml of absolute ethanol and mix well, add 300 mg of TEPA or PEI with a mass fraction of 30% , mixed evenly, placed in a magnetic heating stirrer, stirred at 400r / min and room temperature for 7h, then placed in an oven at 80°C to evaporate the solvent, then placed in a ventilated drying oven, and dried at 100°C to obtain a bifunctional KIT -6 / ZSM-5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com