Processing method for atractylodes macrocephala koidz decoction pieces and atractylodes macrocephala koidz decoction pieces obtained through method

A processing method and technology of Atractylodes macrocephala tablets, which can be applied to pharmaceutical formulas, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of low tablet shape integrity, long soaking time, loss of volatile oil, etc., and achieve good integrity, The effect of shortening the processing cycle and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A processing method for Baizhu decoction pieces, comprising:

[0041] Soaking step: take the Atractylodes macrocephala raw material, add water at a temperature of 10°C to submerge the surface of the raw material for soaking, heat until the water temperature is 35°C during soaking, and the duration of the heating treatment is 5 hours;

[0042] Steaming step: set the material on the water surface, soften the raw material of Atractylodes macrocephala with steam, control the temperature of steaming through the temperature control system to 55°C, and last for 2.5 hours; when steaming, put a cover on the raw material cotton;

[0043] Slicing step: slice the steamed Atractylodes macrocephala raw material, the thickness of the slice is 2mm, to obtain Atractylodes macrocephala slices;

[0044] Drying step: heating and drying the slices with microwaves to obtain decoction pieces of Atractylodes Rhizome.

Embodiment 2

[0046] A processing method for Baizhu decoction pieces, comprising:

[0047] Soaking step: take the Atractylodes macrocephala raw material, add water at a temperature of 20°C to submerge the surface of the raw material for soaking, heat to a water temperature of 40°C during soaking, and the duration of the heating treatment is 5.5 hours;

[0048] Steaming step: set the material on the water surface, soften the raw material of Atractylodes macrocephala with steam, and control the steaming temperature to 50°C through the temperature control system, and the duration is 3 hours; when steaming, cover the raw material with cotton cloth ;

[0049] Slicing step: slice the steamed Atractylodes macrocephala raw material, the thickness of the slice is 2mm, to obtain Atractylodes macrocephala slices;

[0050] Drying step: heating and drying the slices with microwaves to obtain decoction pieces of Atractylodes Rhizome.

Embodiment 3

[0052] A processing method for Baizhu decoction pieces, comprising:

[0053] Soaking step: take the Atractylodes macrocephala raw material, add water at a temperature of 20°C to submerge the surface of the raw material for soaking, heat to a water temperature of 45°C during soaking, and the duration of the heating treatment is 5.5 hours;

[0054] Steaming step: set the material on the water surface, soften the raw material of Atractylodes macrocephala with steam, and control the steaming temperature to 60°C through the temperature control system, and the duration is 3 hours; when steaming, cover the raw material with cotton cloth ;

[0055] Slicing step: slice the steamed Atractylodes macrocephala raw material, the thickness of the slice is 2mm, to obtain Atractylodes macrocephala slices;

[0056] Drying step: heating and drying the slices with microwaves to obtain decoction pieces of Atractylodes Rhizome.

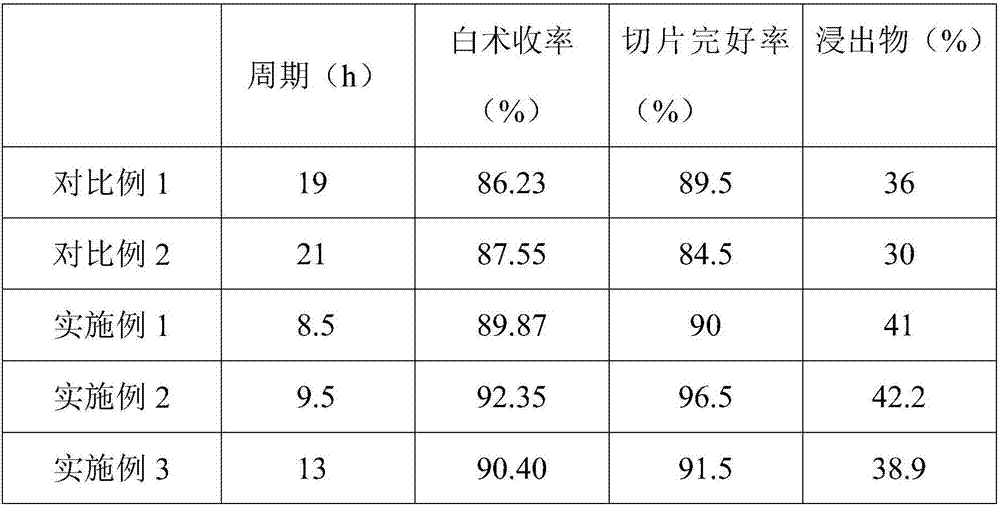

[0057] The processing time, Atractylodes Rhizoma Atractylodes Rhizo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com