Preparation method of easily-digested tea-flavor salted duck eggs

A salted duck egg, easy-to-digest technology, applied in food science and other directions, can solve the problems of poor antibacterial and bacteriostatic ability, few health-care ingredients in duck eggs, and low nutritional and health-care properties, so as to improve health-care function, maintain brain cell vitality, and improve decomposition effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

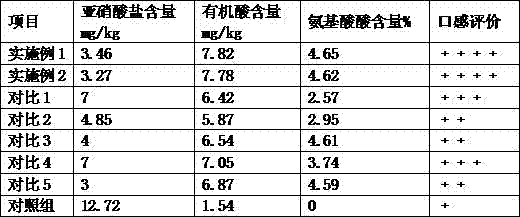

Examples

Embodiment 1

[0021] A kind of preparation method of digestible tea-flavored salted duck egg comprises the following steps:

[0022] (1) Enzymolysis: wash the duck eggs and sterilize them with ultraviolet rays, then immerse them in the mixed enzyme solution in the reaction tank and enzymolyze them for 44 minutes under the conditions of pressure 0.24MPa and temperature 26°C to obtain enzymatic hydrolysis duck eggs; protease, lipase, amylase infiltration Degrade into duck eggs, degrade macromolecular nutrients into small molecules, improve absorption and utilization, and organic acid components can improve anti-oxidation and antibacterial ability, and inhibit the production of nitrite;

[0023] (2) Fermentation: Add the mixed bacterial agent to the tea mixture, first carry out vacuum fermentation for 15 hours, and then magnetize it in a 2.5MPa magnetizer for 37 minutes to obtain a magnetized fermentation broth with high penetration capacity, and then enzymatically hydrolyze duck eggs Immerse ...

Embodiment 2

[0036] Present embodiment 2 is compared with embodiment 1, and step changes in the following aspects:

[0037]For the ultraviolet sterilization described in step (1), the intensity of the ultraviolet light is 400 lux, and the time is 29 minutes.

[0038] For the mixed enzyme liquid described in step (1), the parts by mass of each prepared ingredient are:

[0039] 117 parts of sterile water, 1.4 parts of protease, 1.1 parts of lipase, 1.7 parts of amylase, 3.8 parts of folic acid, 5.8 parts of citric acid, and 2.9 parts of caffeic acid.

[0040] Step (1) enzymatic hydrolysis, its process parameters are:

[0041] Enzymolysis was carried out for 46 minutes at a pressure of 0.27 MPa and a temperature of 28°C.

[0042] The mixed bacterial agent described in step (2), wherein the mass ratio of yeast: lactic acid bacteria: aspergillus oryzae is 2:2:3, and the added amount of the mixed bacterial agent is 3.8% of the mass of the tea mixture.

[0043] The tea mixture described in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com