Thin type rammed earth wall and manufacturing method thereof

A rammed earth wall and thin technology, applied in the direction of covering/lining, building, building structure, etc., can solve the problem that different colors and materials cannot be layered and laminated, and achieve a beautiful finished product effect and satisfy antique decoration The effect of sexual demands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

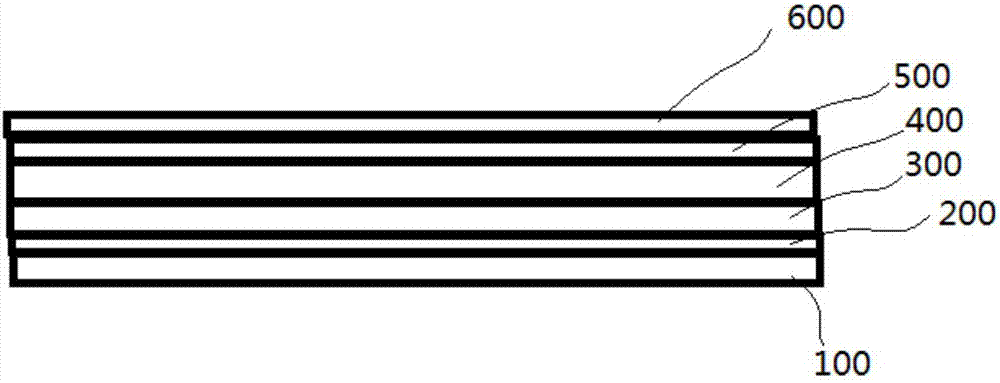

[0028] see figure 1 , the thin rammed earth wall shown in the figure is attached to the base surface 100, and it is composed of a leveling putty layer 200 attached to the base surface 100 and a khaki water-based alkali-resistant primer attached to the leveling putty layer 200 from the inside to the outside. layer 300 , a rammed earth layer 400 attached to the khaki anti-alkali primer layer 300 , a sandy surface layer 500 attached to the rammed earth layer 400 , and an overcoat layer 600 attached to the sandy surface layer 500 .

[0029] The preparation method of the above-mentioned thin rammed earth wall comprises the following steps:

[0030] (1) Scrape the leveling putty on the base surface 100 formed by the cement mortar plastering surface or the thermal insulation mortar plastering surface to form a layer of leveling putty layer 200, and the unevenness of the base surface plays and achieves a leveling effect;

[0031] (2) Spray or roll a khaki water-based alkali-resistant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com