Method for separating and purifying teicoplanin

A technique for separation and purification of teicoplanin, applied in the field of biomedicine, can solve the problems of large solvent usage, high production cost, expensive chromatographic packing, etc., and achieve the effect of changing appearance and color, improving effective components, and reducing side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

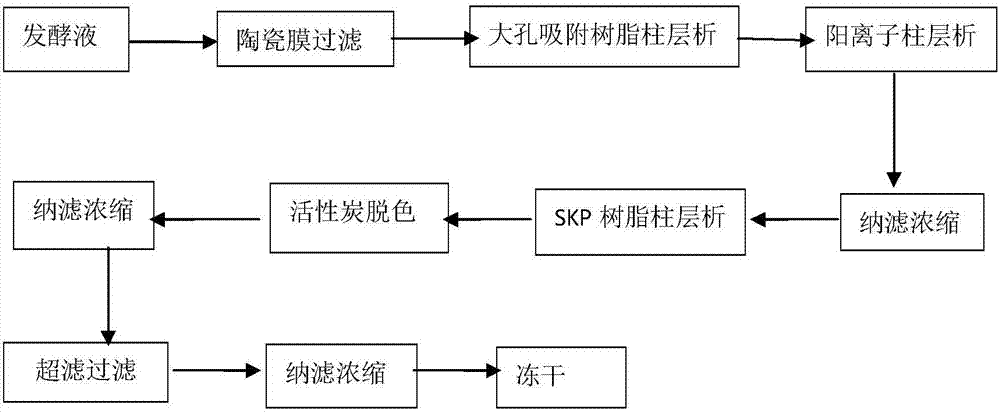

Method used

Image

Examples

Embodiment 1

[0044] Teicoplanin fermentation broth 25L, fermented broth titer 3200mg / L, adjust pH value to 10.8 with 1mol / L sodium hydroxide solution, filter with ceramic membrane, when concentrated to 8L, add 4L to ceramic membrane impermeable liquid Purified water, adjust the pH value to 10.8 with 1mol / L sodium hydroxide solution, stir for 5min, and continue to filter with ceramic membrane. The above operation was repeated 11 times, and a total of 44 L of purified water was added. Sampling, HPLC detection of teicoplanin 1221mg / L in the ceramic membrane permeate solution, ceramic membrane filtration ends. A total of 61L of ceramic membrane permeate was collected, containing 74.4g of teicoplanin.

[0045]Add absolute ethanol to the ceramic membrane permeate, adjust the alcohol content to 16%, adjust the pH value to 6.5 with 1mol / L hydrochloric acid, load the sample on a macroporous adsorption resin column, the resin model is HZ818, the column volume is 7L, and the resin column diameter is...

Embodiment 2

[0054] Receive 20L of fermentation broth to be put into the tank, the titer of the fermentation broth is 3720mg / L, adjust the pH value to 11 with 1mol / L sodium hydroxide solution, filter with ceramic membrane, when it is concentrated to 6L, add 3L to the impermeable liquid of ceramic membrane Ethanol with an alcohol content of 5%, adjust the pH value to 11 with 1mol / L sodium hydroxide solution, stir for 5min, and continue to filter with a ceramic membrane. The above operation was repeated 11 times, and a total of 33 L of 5% ethanol was added. Sampling, HPLC detection of teicoplanin 1421mg / L in the ceramic membrane permeate liquid, ceramic membrane filtration ends. A total of 47L of ceramic membrane permeate was collected, containing 67g of teicoplanin.

[0055] Add absolute ethanol to the ceramic membrane permeate, adjust the alcohol content to 20%, adjust the pH value to 7 with 1mol / L hydrochloric acid, load the sample on a macroporous adsorption resin column, the resin mode...

Embodiment 3

[0064] Receive 25L of fermentation broth to be put into the tank, the titer of the fermentation broth is 3521mg / L, adjust the pH value to 11.2 with 1mol / L sodium hydroxide solution, filter with ceramic membrane, when concentrated to 8L, add 4L to the impermeable liquid of ceramic membrane Alcohol is 10% ethanol, adjust the pH value to 11.2 with 1mol / L sodium hydroxide solution, stir for 5min, and continue to filter with ceramic membrane. The above operation was repeated 11 times, and a total of 44 L of 10% ethanol was added. Sampling, HPLC detection of teicoplanin 1320mg / L in ceramic membrane permeate liquid, ceramic membrane filtration ends. A total of 60L of ceramic membrane permeate was collected, containing 79g of teicoplanin.

[0065] Add absolute ethanol to the ceramic membrane permeate, adjust the alcohol content to 15%, adjust the pH value to 6.8 with 1mol / L hydrochloric acid, load the sample on a macroporous adsorption resin column, the resin model is XAD16, the colu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fermentation titer | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com