Steam reduced graphene oxide conductive high-polymer composite film, and preparation method and application thereof

A technology of conductive polymers and polymers, applied in the direction of graphene, chemical instruments and methods, equipment for manufacturing conductive/semiconductive layers, etc., can solve the problems such as the limitation of reduced graphene oxide film formation, and achieve simple preparation methods , Good electrical conductivity, improve the effect of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

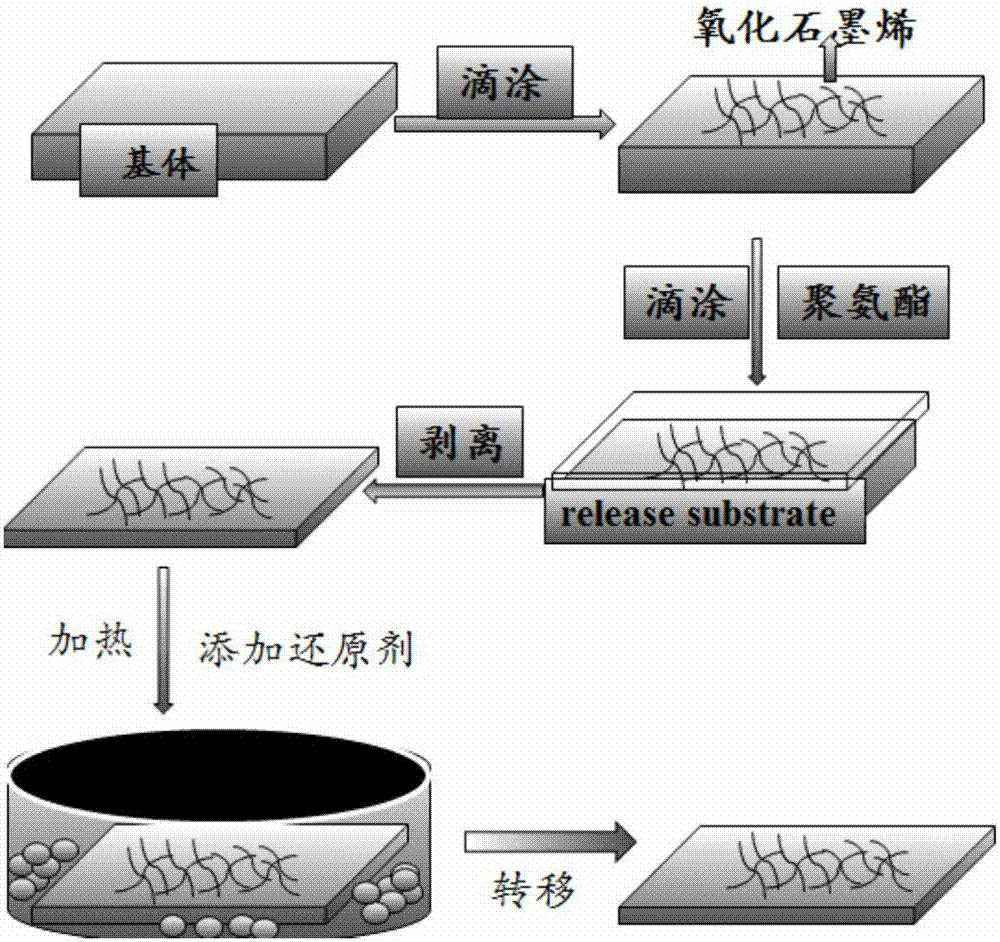

[0026] Embodiment 1 (manufacturing process such as figure 1 shown)

[0027] 1. Disperse 10 mg of graphene oxide in absolute ethanol, stir and sonicate for 1 hour to obtain a graphene oxide solution with a concentration of 3.5 mg / ml, and heat and dry it on the polymer substrate to obtain a conductive layer;

[0028] 2. Dissolve 200mg of polyurethane PU in N,N dimethylacetamide (DMAC) to prepare a 100mg / ml solution, heat, stir and ultrasonically make the solution uniform to obtain a polyurethane PU solution;

[0029] 3. Drop-coat the polyurethane PU solution on the conductive layer obtained in the above step 1, place it in a vacuum drying oven and heat it at 70°C for 12 hours, and then vacuumize it for 24 hours to obtain a flexible graphene oxide polymer film;

[0030] 4. Peel off the graphene oxide polymer film from the substrate, then place it in a closed container, add 1.5ml of hydrazine hydrate solution dropwise around the graphene oxide polymer film, and then place the clo...

Embodiment 2

[0033] 1. Disperse 10 mg of graphene oxide in absolute ethanol, stir and sonicate for 1 hour to obtain a graphene oxide solution with a concentration of 3.5 mg / ml, and heat and dry it on the polymer substrate to obtain a conductive layer;

[0034] 2. Dissolve 200mg of polyurethane PU in N,N dimethylacetamide (DMAC) to prepare a 100mg / ml solution, heat, stir and ultrasonically make the solution uniform to obtain a polyurethane PU solution;

[0035] 3. Drop-coat the polyurethane PU solution on the conductive layer obtained in the above step 1, place it in a vacuum drying oven and heat it at 70°C for 12 hours, and then vacuumize it for 24 hours to obtain a flexible graphene oxide polymer film;

[0036] 4. The graphene oxide polymer film is peeled off from the substrate, and then placed in an airtight container, and the hydrazine hydrate-ammonia water mixed solution of 1.5ml is added dropwise around the graphene oxide polymer film (the volume ratio ratio of hydrazine hydrate and am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com