Heat conduction oil type double-cylinder hot melting kettle convenient for replacement of inner containers

A technology of heat-conducting oil and hot-melt kettle, which is applied in the field of paint melting equipment before scribing, can solve the problems of affecting construction efficiency and molding effect, increasing the construction cost of the construction team, and improving the melting speed of paint, so as to achieve the improvement of melting speed and quality, The effect of improving construction efficiency and reducing expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

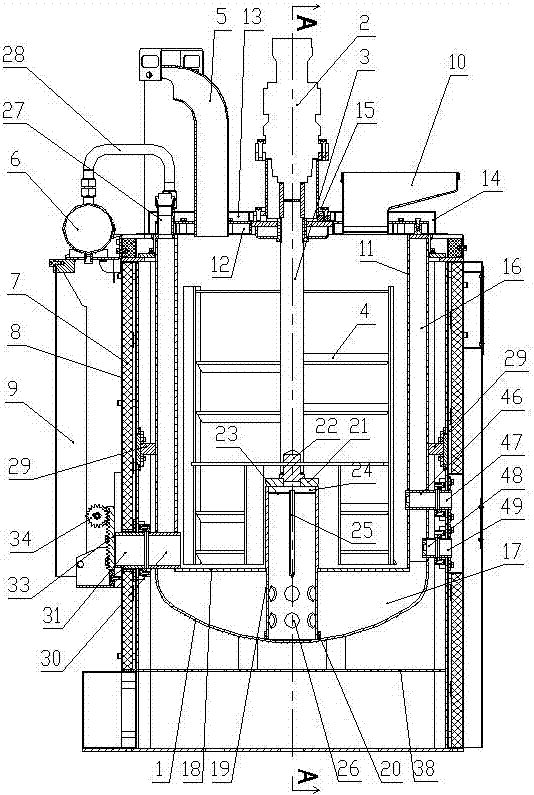

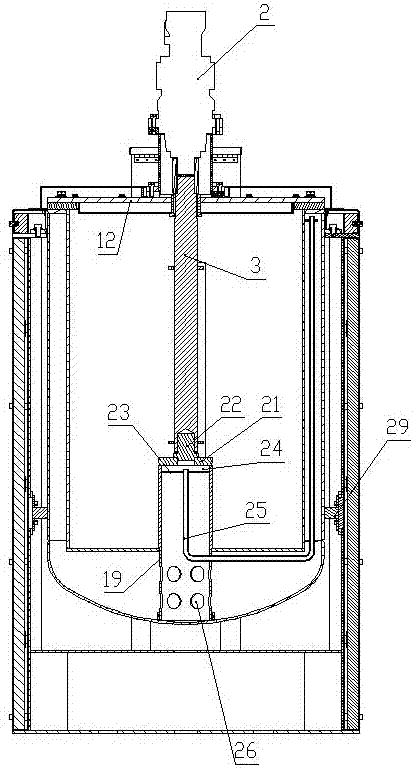

[0033] Such as Figure 1 to Figure 5 As shown, the heat-conducting oil-type double-cylinder hot-melt kettle that is easy to replace the inner tank of the present invention includes a hot-melt kettle body, a gas-fired stove, an automatic temperature control system and an independent power station. The hot-melt kettle body is arranged side by side with two , the gas-fired stove and the automatic temperature control system are matched with the two hot-melt kettle bodies,

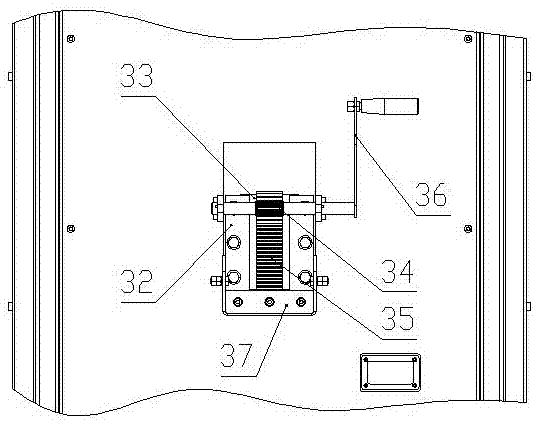

[0034] The body of a single hot-melt kettle includes a liner 1, a reducer 2, a stirring shaft 3, a stirring blade 4, a smoke exhaust pipe 5, a heat transfer oil storage tank 6, a heat insulation layer 7, a protective chamber 8, a casing 9, a feeding port 10 and an outlet The material pipe, the reducer 2 is installed above the inner tank 1, the stirring shaft 3 is connected to the reducer 2, and the stirring blade 4 is fixedly connected to the stirring shaft 3. The inner tank 1 is pressed by a special steel plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com