Lithium-rich manganese-based layered positive electrode material and preparation method therefor

A positive electrode material, lithium-rich manganese technology, applied in the field of lithium-rich manganese-based layered positive electrode materials and its preparation, can solve the problems of aggravated side reactions between positive electrode materials and electrolytes, decreased electrochemical performance, and material performance degradation, and achieve improved battery performance. Chemical properties, good structural consistency, low voltage drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

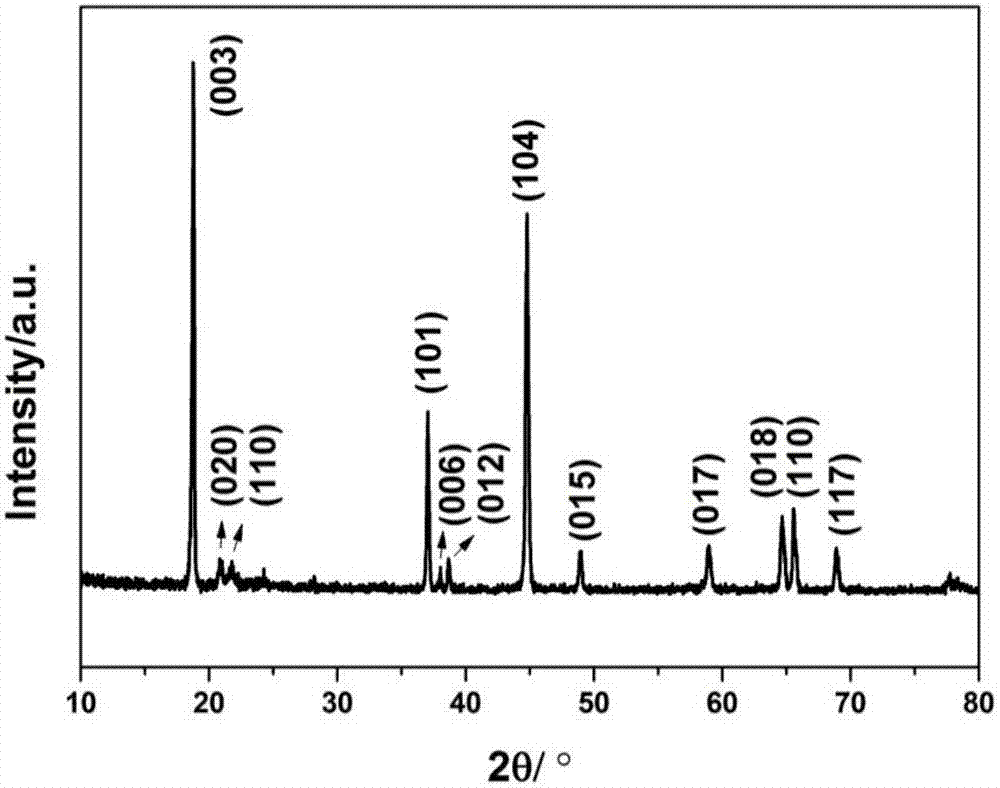

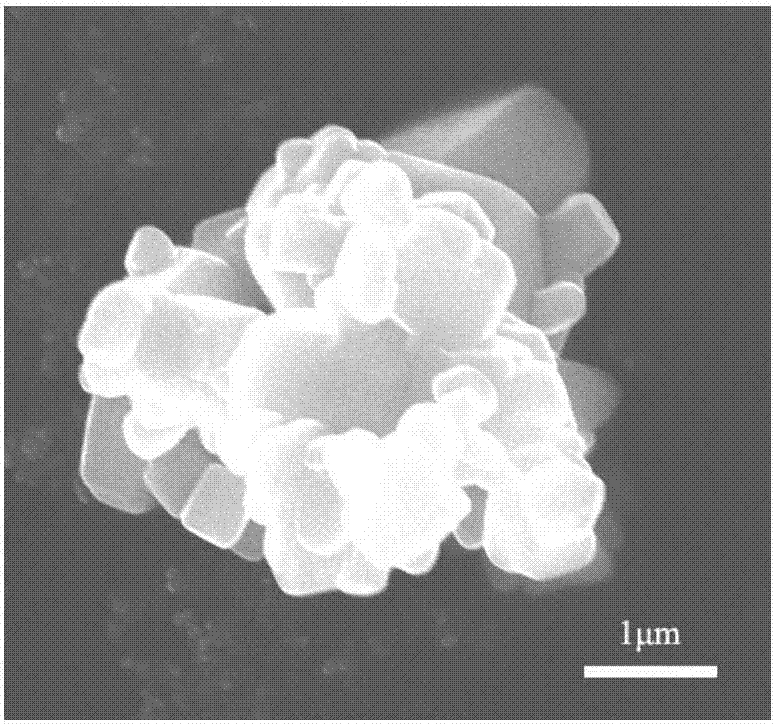

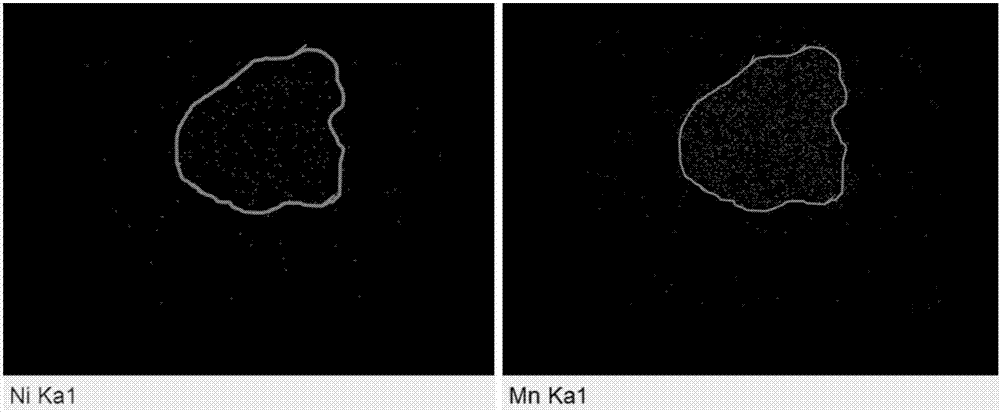

[0049] A lithium-rich manganese-based layered cathode material, the chemical formula of which is Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 , the core part is rich in nickel elements, and the outside is rich in manganese and cobalt elements. The above-mentioned lithium-rich manganese-based layered positive electrode material Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 The preparation method comprises the following steps:

[0050] (1) 4.12 g of nickel sulfate hexahydrate was dissolved in 11 mL of deionized water to obtain a green transparent solution 1;

[0051] (2) 10.23g of anhydrous sodium carbonate and 1.91g of ammonium bicarbonate were dissolved in 65mL of deionized water to obtain a colorless and transparent solution 2;

[0052] (3) 11.00 g of manganese sulfate monohydrate and 4.41 g of cobalt sulfate heptahydrate were dissolved in 54 mL of deionized water to obtain brown transparent solution 3;

[0053](4) First, add 50mL of deionized water into the three-necked flask as the bo...

Embodiment 2

[0063] A lithium-rich manganese-based layered cathode material, the chemical formula of which is Li 1.2 mn 0.6 Ni 0.2 o 2 , the core part is rich in nickel elements, and the outside is rich in manganese elements. The lithium-rich manganese-based layered cathode material Li 1.2 mn 0.6 Ni 0.2 o 2 The preparation method comprises the following steps:

[0064] (1) 6.1770 g of nickel sulfate hexahydrate was dissolved in 17 mL of deionized water to obtain a green transparent solution 1;

[0065] (2) 10.23g of anhydrous sodium carbonate and 1.91g of ammonium bicarbonate were dissolved in 65mL of deionized water to obtain a colorless and transparent solution 2;

[0066] (3) Dissolve 11.9328 g of manganese sulfate monohydrate in 48 mL of deionized water to obtain a brown transparent solution 3;

[0067] (4) First, add 50mL of deionized water into the three-necked flask as the bottom solution, set the temperature of the water bath to 45°C, and the stirring speed at 750rpm. After...

Embodiment 3

[0072] A lithium-rich manganese-based layered cathode material, the chemical formula of which is Li 1.2 mn 0.7 Ni 0.1 o 2 , the core part is rich in nickel elements, and the outside is rich in manganese elements. The lithium-rich manganese-based layered cathode material Li 1.2 mn 0.7 Ni 0.1 o 2 The preparation method comprises the following steps:

[0073] (1) 4.5627g of nickel sulfate hexahydrate was dissolved in 12mL of deionized water to obtain a green transparent solution 1;

[0074] (2) 6.89g of anhydrous sodium carbonate and 0.91g of ammonium bicarbonate were dissolved in 65mL of deionized water to obtain a colorless and transparent solution 2;

[0075] (3) 9.464g manganese sulfate monohydrate was dissolved in 56mL deionized water to obtain brown transparent solution 3;

[0076] (4) First, add 50mL of deionized water into the three-necked flask as the bottom solution, set the temperature of the water bath to 40°C, and the stirring speed at 600rpm. After the condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com