Composite electrode materials, preparation method thereof, and application thereof

A composite electrode and carbon material technology, applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, battery electrodes, etc., can solve the problems of unfavorable internal active material utilization, large nickel hydroxide particle size, and poor product uniformity, and achieve Environmentally friendly after-treatment, no need for post-treatment, and easy-to-control conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Prepare 100mL of 1M nickel chloride solution and 100mL of 2M sodium hydroxide solution. With stirring at room temperature, drop the sodium hydroxide solution into the nickel chloride solution. Wash by centrifugation for three times, and dry overnight in an oven at 60°C to obtain nickel hydroxide;

[0055] Weigh 0.5 g of the prepared nickel hydroxide, mix it with ammonia water with a mass percentage concentration of 28%, and prepare a nickel-ammonia mixed solution, so that the mass concentration of the complex solution is 1 mg / mL;

[0056] Weigh 95 mg of activated carbon, add 5 mL of the prepared 1 mg / mL nickel-ammonia mixed solution, sonicate for 10 minutes, and then place it on a hot stage at 60 ° C until the ammonia water is completely volatilized to obtain a nickel hydroxide-activated carbon composite electrode material with a loading capacity of 5%. .

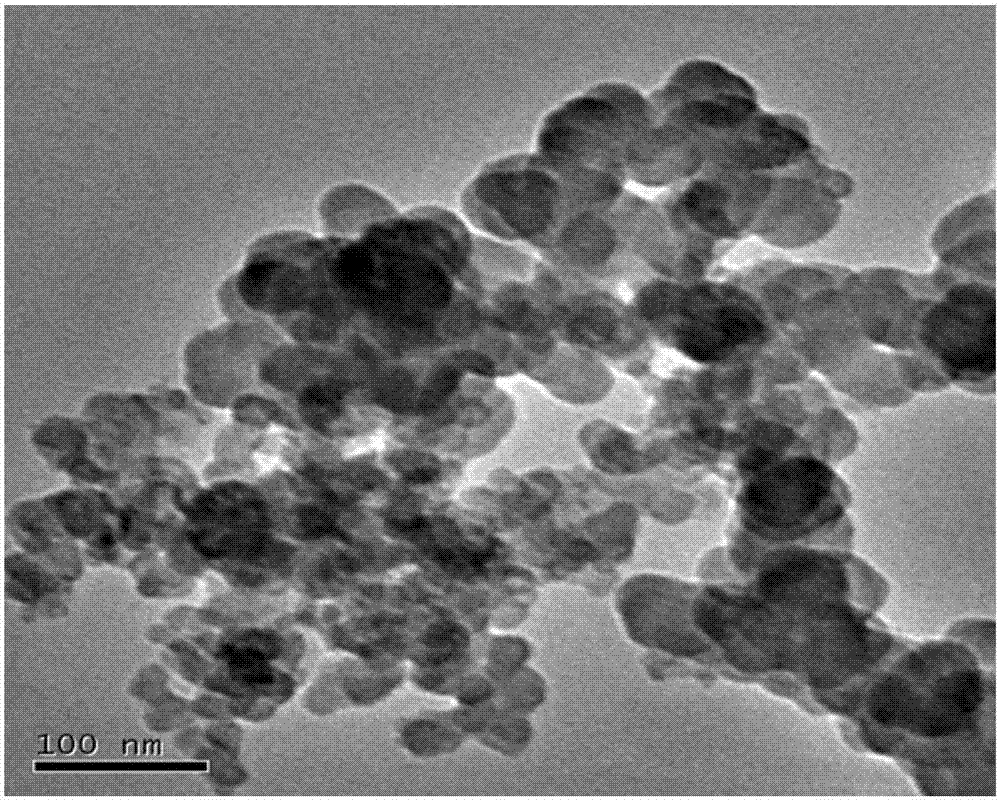

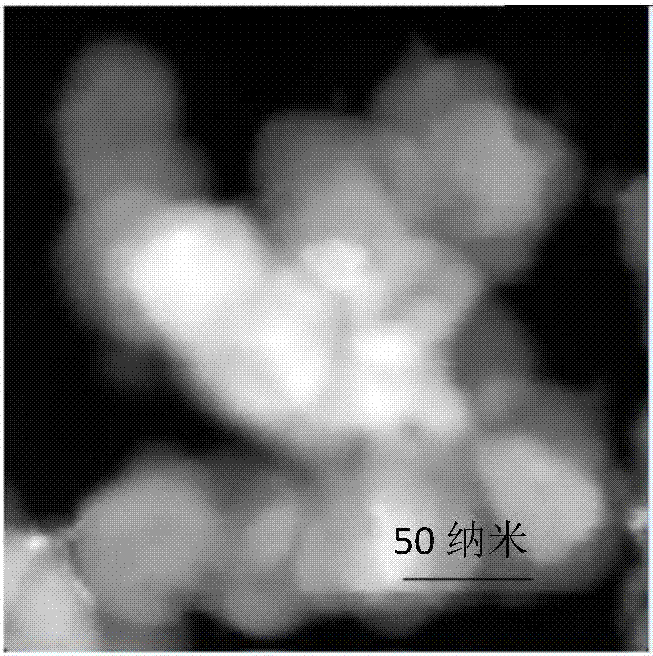

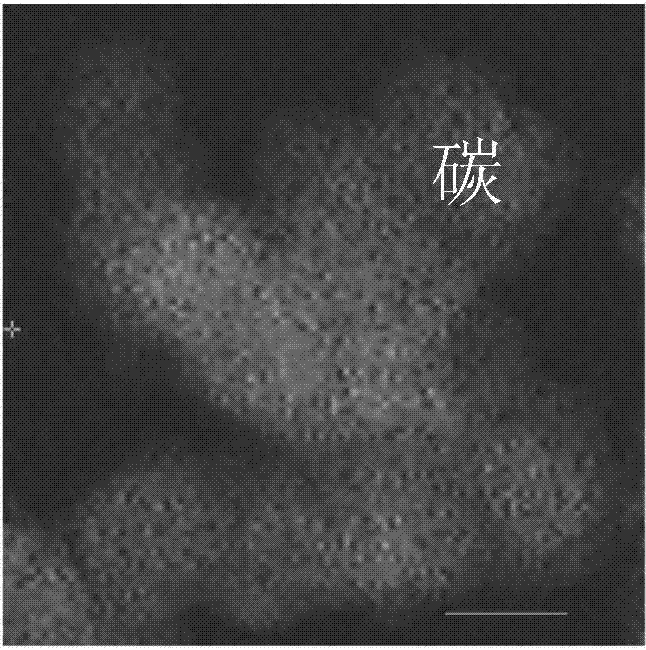

[0057] Its characterization results and electrochemical performance test data are attached Figure 1-5 shown.

...

Embodiment 2

[0064] Prepare 100mL of 1M cobalt nitrate solution and 100mL of 2M potassium hydroxide solution. Under stirring at room temperature, drop the potassium hydroxide solution into the cobalt nitrate solution, stir for 30 minutes after the addition is completed, and centrifugally wash the obtained product with deionized water Three times, dry overnight in an oven at 80°C to obtain cobalt hydroxide;

[0065] Weigh 0.5 g of the prepared cobalt hydroxide, mix it with ethylenediamine solution with a mass percentage concentration of 99.9%, and prepare a cobalt ethylenediamine complex solution, so that the mass concentration of the complex solution is 0.01 mg / mL;

[0066] Weigh 99.99 mg of carbon nanotubes, add 1 mL of the prepared 0.01 mg / mL cobalt ethylenediamine complex solution, sonicate for 10 minutes, then place on a hot stage at 100 ° C until the ethylenediamine is completely volatilized, and the loading capacity is obtained as 0.01% cobalt hydroxide-carbon nanotube composite elec...

Embodiment 3

[0069] Purchase commercial analytically pure manganese dioxide;

[0070] Weigh 0.5g of manganese dioxide, mix it with a 50% mass percent methylamine solution, and prepare a manganese methylamine complex mixed solution, so that the mass concentration of the complex solution is 10 mg / mL;

[0071] Weigh 200mg of graphene, add it to 80mL of the prepared 10mg / mL manganese methylamine complex solution, sonicate for 10min, then place on a hot stage at 60°C and heat until the methylamine solution is completely volatilized to obtain an oxide with a loading capacity of 80%. Manganese-graphene composite electrode materials.

[0072] The three-electrode electrochemical performance test was carried out on the manganese hydroxide-graphene composite electrode material with a loading capacity of 80% prepared in this example. The results showed that: at a scan rate of 5 mV / s, the mass specific capacity of the full electrode reached 190 F / g, and the activity The specific capacity of manganese ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com