Electrochemiluminescence material and one-pot preparation method and application thereof

A technology of electrochemistry and luminescence materials, applied in chemiluminescence/bioluminescence, analysis by chemical reaction of materials, etc., can solve the problems of complex electrochemical system, cumbersome analysis steps, limited application of electrochemiluminescence, etc. Achieve the effect of easy large-scale application, obvious color change, and large-scale production and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

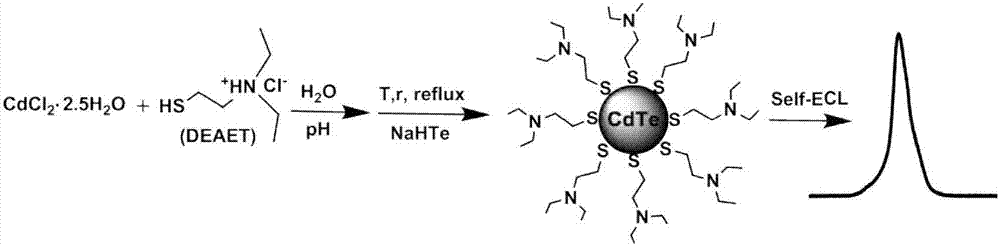

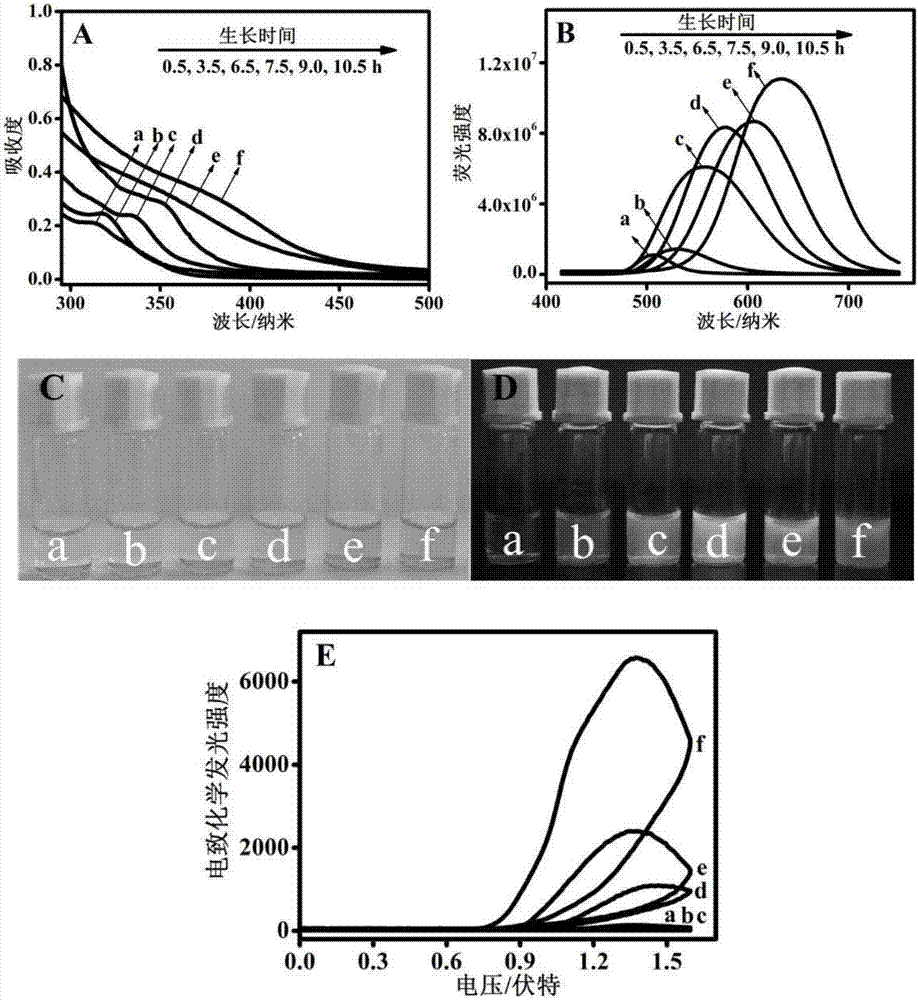

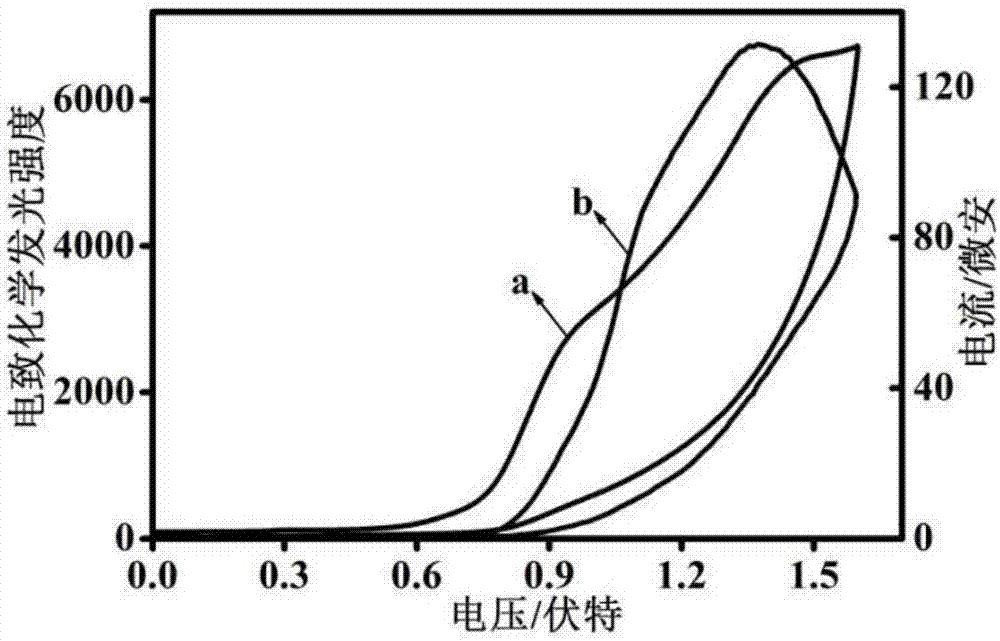

[0025] (1) One-pot preparation of red fluorescent 2-diethylaminoethanethiol-coated cadmium telluride quantum dots:

[0026] (a) Take 50.8mg tellurium powder and 10mL H 2 O was added to a 25mL round-bottomed flask, and nitrogen gas was introduced for 15 minutes to remove oxygen in the solution. After the system was heated to 80°C in an 80°C oil bath, 37.8mg of NaBH was quickly added 4 , reacted for 25min, the color of the solution gradually turned into dark purple, and NaHTe solution was obtained;

[0027] (b) Take 91.3mg CdCl 2 2.5H 2 O and 40mL H 2 O was added to a 50mL round bottom flask, magnetically stirred to dissolve it, and then 158.7mg of 2-diethylaminoethanethiol hydrochloride was added to it, and the pH of the system was adjusted to 5.5 with 0.1M NaOH; The obtained NaHTe solution was quickly injected into the above system, and the color of the solution quickly turned reddish brown. It was placed in an oil bath at 120°C and refluxed for 10.5 hours. Finally, it was...

Embodiment 2

[0041] (1) One-pot preparation of orange fluorescent 2-diethylaminoethanethiol-coated cadmium telluride quantum dots:

[0042] (a) Take 50.8mg tellurium powder and 10mL H 2 O was added to a 25mL round-bottomed flask, and nitrogen gas was introduced for 20 minutes to remove the oxygen in the solution. After the system was heated to 78°C in an 80°C oil bath, 40mg of NaBH was quickly added. 4 , reacted for 30min, the color of the solution gradually turned into dark purple, and NaHTe solution was obtained;

[0043] (b) Take 91.8mg CdCl 2 .2.5H 2 O and 40mL H 2 O was added to a 50mL round bottom flask, magnetically stirred to dissolve it, and then 159mg of 2-diethylaminoethanethiol hydrochloride was added to it, and the pH of the system was adjusted to 5.56 with 0.2M NaOH; The obtained NaHTe solution was quickly injected into the above system, and the color of the solution quickly turned reddish brown. It was placed in an oil bath at 125°C and refluxed for 9 hours. Finally, it ...

Embodiment 3

[0055] (1) One-pot preparation of yellow fluorescent 2-diethylaminoethanethiol-coated cadmium telluride quantum dots:

[0056] (a) Take 25.4mg tellurium powder and 5mL H 2 O was added to a 25mL round-bottomed flask, and nitrogen gas was introduced for 15 minutes to remove the oxygen in the solution. After the system was heated to 80°C in an oil bath at 80°C, 18.9 mg of NaBH was quickly added. 4 , reacted for 25min, the color of the solution gradually turned into dark purple, and NaHTe solution was obtained;

[0057] (b) Take 45.9mg CdCl 2 2.5H 2 O and 20mL H 2 O was added to a 50mL round bottom flask, stirred magnetically to dissolve it, and then 79.4mg of 2-diethylaminoethanethiol hydrochloride was added to it, and the pH of the system was adjusted to 5.6 with 0.1M NaOH; 0.2mL of step (a) was taken with a syringe The prepared NaHTe solution was quickly injected into the above system, and the color of the solution quickly turned reddish brown. It was placed in an oil bath ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com