Pivot pin type pull pressure sensor

A pull pressure sensor and pull pressure technology, applied in the field of sensors, can solve problems such as unsatisfactory waterproof performance, unusable sensors, and affecting work efficiency, and achieve good waterproof performance, reasonable structure, and continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is further described below in conjunction with embodiment and accompanying drawing.

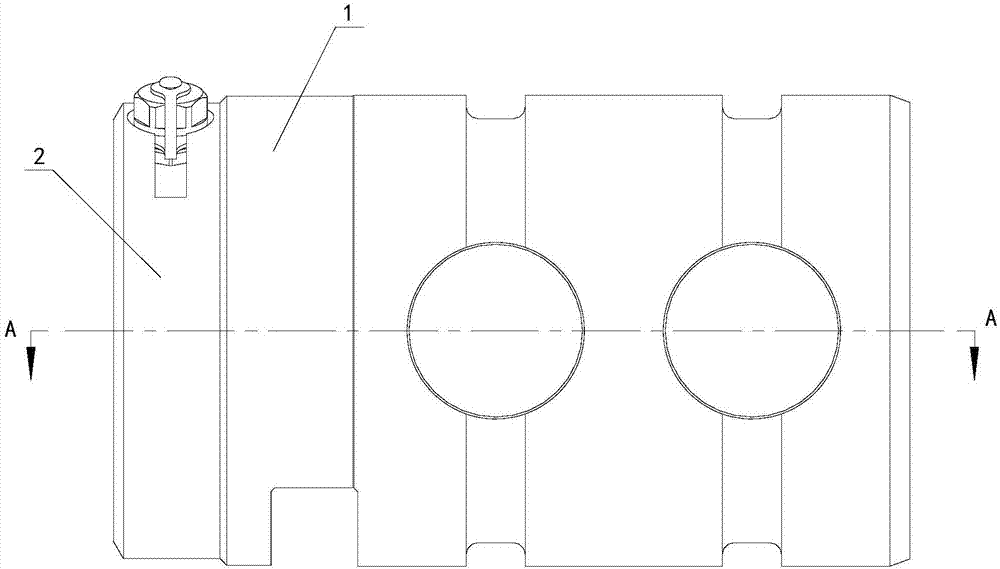

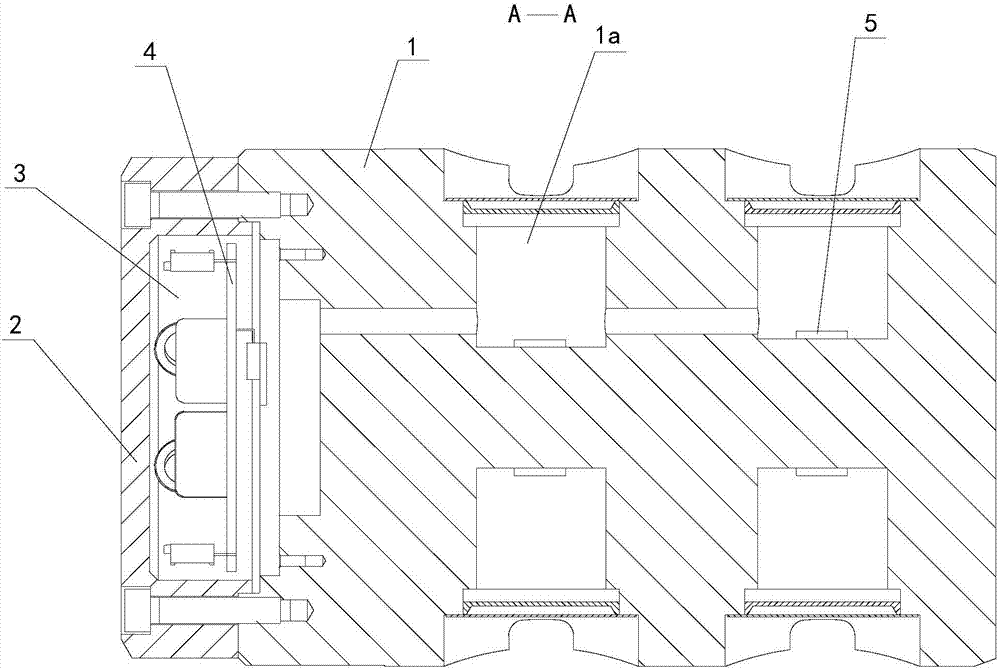

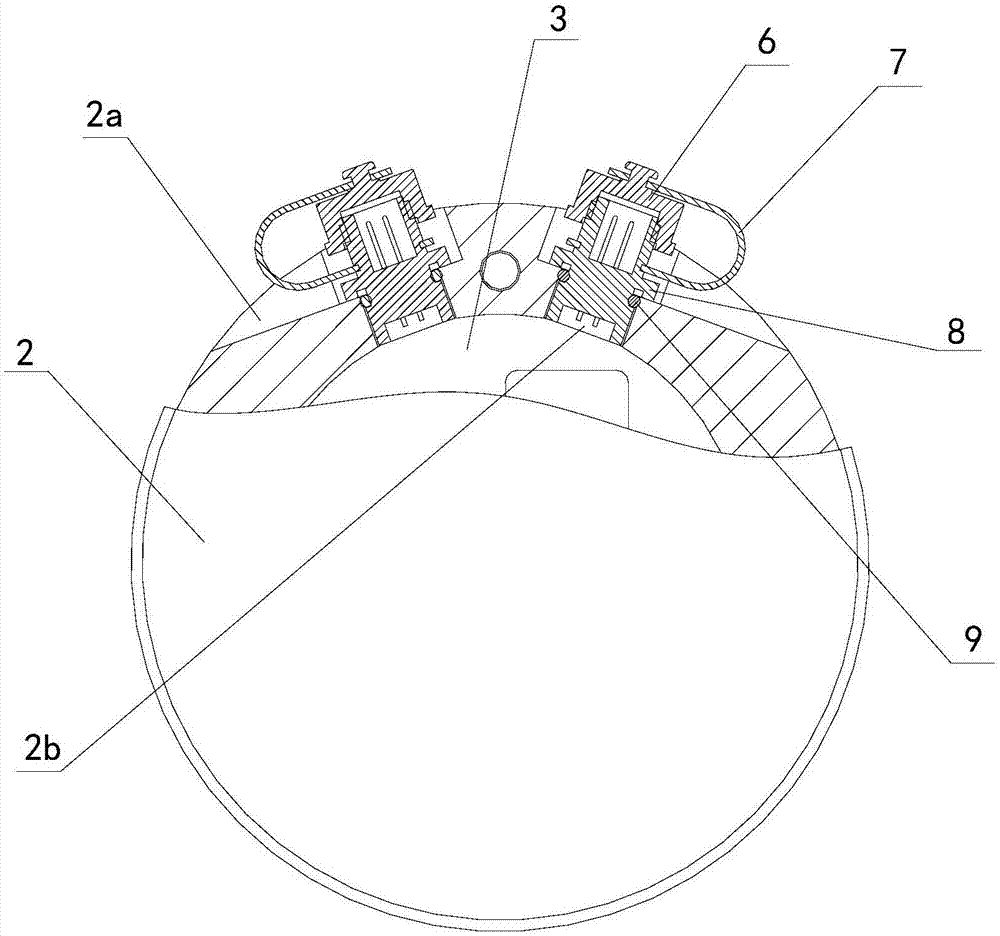

[0011] see figure 1 , figure 2 , image 3

[0012] The pin-type tensile pressure sensor provided by the present invention has a cylindrical strain body 1, four blind holes 1a are arranged on the strain body 1, and strain gauges 5 are attached to the inner walls of the blind holes 1a. One end of the strain body 1 is connected with an end cover 2 , and an electrical compartment 3 is formed between the end cover 2 and the strain body 1 . The electrical compartment 3 is equipped with a transmission circuit board 4 , and an output terminal 8 is installed on the outside of the end cover 3 .

[0013] In the present invention, there are two sets of strain gauges 5, two output terminals 8, and two pull-pressure test units, each pull-pressure test unit consists of a set of strain gauges 5, an output terminal 8 and a transmission circuit board 4 The above transmission c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com