Tunnel inverted arch side wall integral steel formwork and construction method thereof

A steel formwork and overall technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of steel formwork rigidity, insufficient vibration, and many construction workers, so as to ensure rigidity and self-weight, reduce construction personnel, The effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

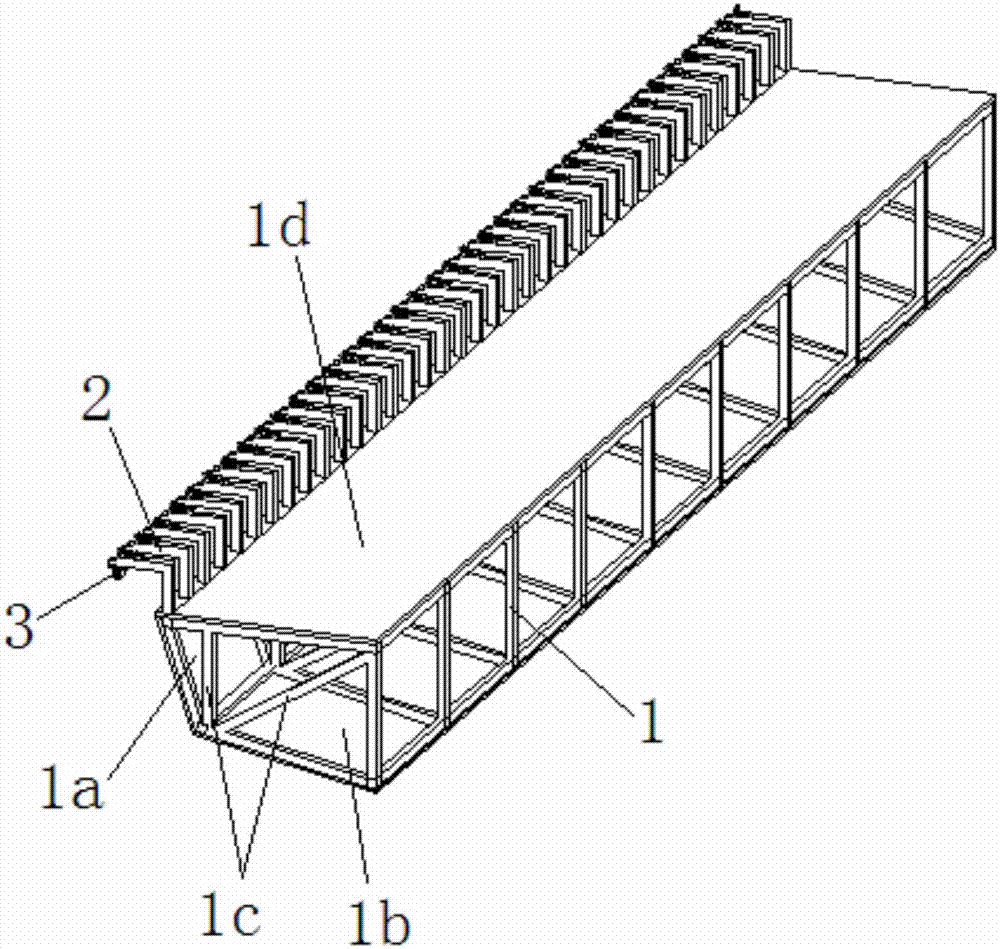

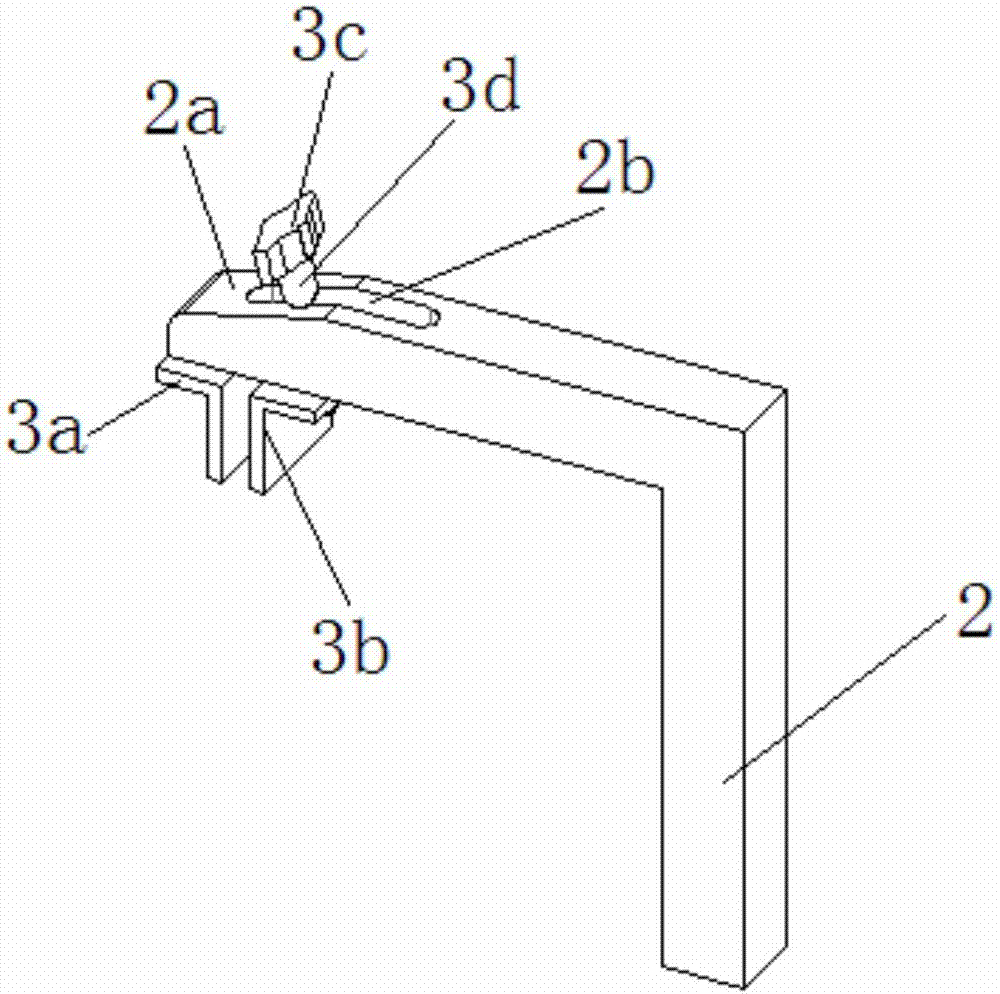

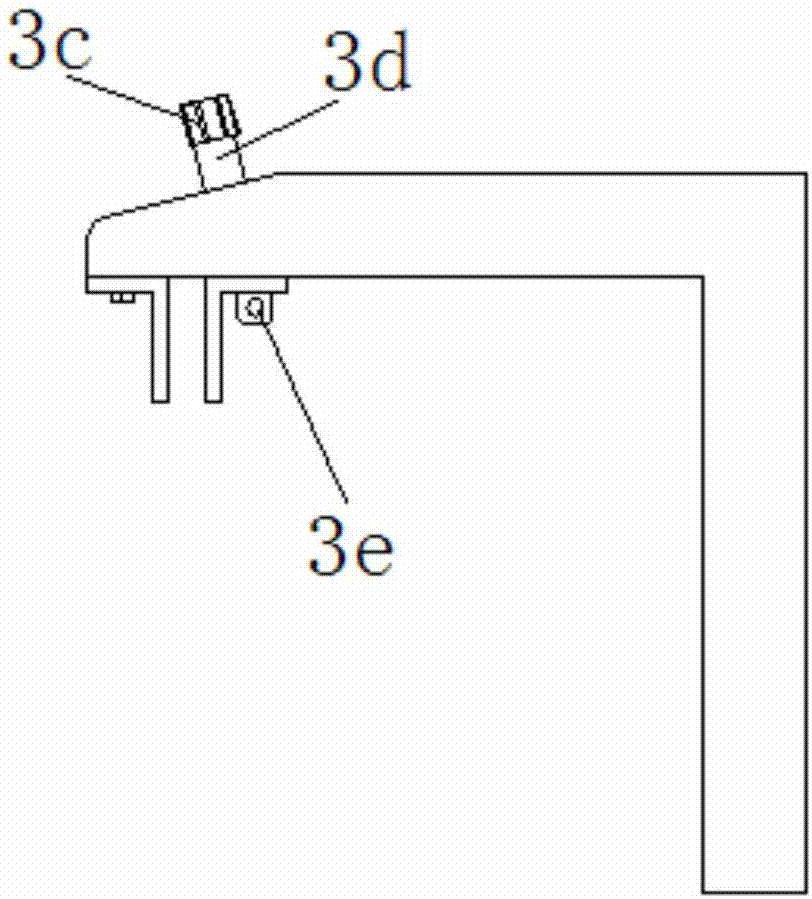

[0031] combine figure 1 — image 3 As shown, an integral steel form for the side wall of the inverted arch of a tunnel is mainly composed of a steel form main body 1, a waterstop hanger 2 and a waterstop clamp 3, and the three are integrally formed. There is more than one waterstop hanger 2, and each waterstop hanger 2 is correspondingly provided with a waterstop clamp 3.

[0032] The main body 1 of the steel mold adopts a welded steel frame structure with a closed ring cross section, and the welded steel frame structure is welded together by angle steel, channel steel or I-beam. Except the top surface 1d, the outer surface 1a and the bottom surface 1b of the steel mold main body 1 are covered with steel plates. The thickness of the steel plate can be 3mm or other specifications.

[0033] The outline of the outer side 1a matches the outline of the inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com