Functional mugwort non-woven fabric and preparation method thereof

A non-woven fabric and functional technology, applied in the field of wormwood functional non-woven fabric and its preparation, can solve the problems of reduced water absorption, poor dimensional stability, etc., and achieve the effects of reducing loss, ensuring loss, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

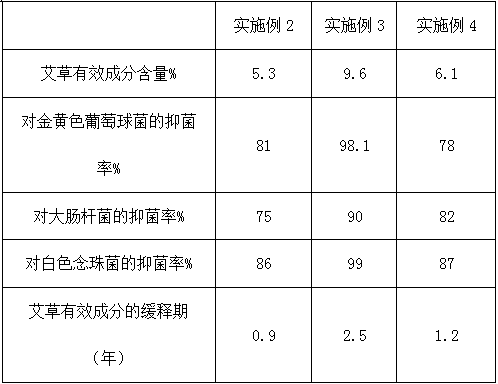

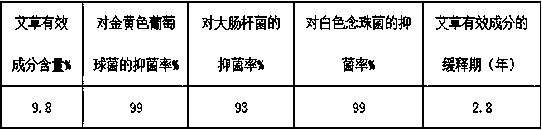

Examples

preparation example Construction

[0043] (2) Preparation of wormwood solution:

[0044] The mass ratio of the wormwood extract to the non-woven fabric is 5%, and the wormwood extract is prepared.

[0045] In a temperature-adjustable automatic stirring container, add cold water (that is, normal temperature water), add 5% (OWF) wormwood extract while adding water, keep stirring to heat up, stir at 80-100 rpm, and keep a constant speed; When the temperature reaches 35°C, keep stirring for half an hour, and then raise the temperature to 60°C until the wormwood extract is completely dissolved.

[0046] Insulate and stir until the wormwood extract powder is completely dissolved in water, filter through a 120-mesh sieve (the pore size of the sieve is 120 mesh), and take the filtrate.

[0047] Add glacial acetic acid aqueous solution to the filtrate, adjust the pH value of the liquid in this container to 6.0~7.5, set aside. According to 1 ton of filtrate, add 250ml of glacial acetic acid aqueous solution, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com