Genetically engineered bacterium with gamma-terpinene synthesis capacity and constructing method and application thereof

A technology of genetically engineered bacteria and terpinene, applied in the field of genetic engineering, can solve problems such as low content, high energy consumption, and restrictions on mass application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 Construction of recombinant plasmid pHW2 carrying genes encoding hydroxymethylglutaryl-CoA synthetase, hydroxymethylglutaryl-CoA reductase, geranyl pyrophosphate synthetase and γ-terpinene synthase

[0050] The recombinant plasmid pHW2 was constructed through molecular biology-related experiments, which carried the hydroxymethylglutaryl-CoA synthetase gene mvaS (sequence registration number: GenBank: AAG02439.1), hydroxymethylglutaryl-CoA synthetase gene Enzyme gene mvaE (sequence accession number is GenBank: AAG02439.1), geranyl pyrophosphate synthase gene GPPS2 (sequence accession number is GenBank: AAN01134.1) and γ-terpinene synthase gene TPS2 (sequence accession number is GenBank: ID: KR920616), through the heterologous expression of the recombinant vector, the above-mentioned foreign gene was overexpressed in Escherichia coli (E.coli BL21(DE3)), and the biosynthesis of γ-terpinene was realized.

[0051] The MVA pathway first converts glucose to mevalonat...

Embodiment 2

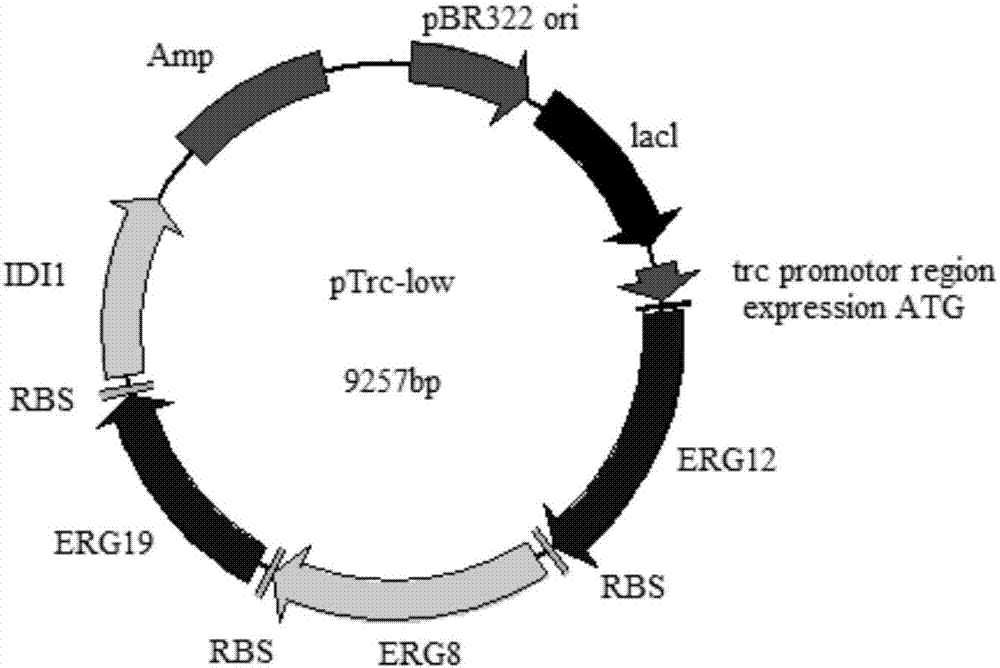

[0055] Example 2 Construction of recombinant plasmid pTrc-low carrying mevalonate kinase gene, mevalonate phosphokinase gene, mevalonate pyrophosphate decarboxylase gene and isopentenyl pyrophosphate isomerase coding gene

[0056] The pTrc-low vector was constructed according to the Lego DNA assembly method established in the laboratory, and contains the mevalonate kinase gene (ERG12) and mevalonate phosphate derived from Saccharomyces cerevisiae (S. Kinase gene (ERG8), mevalonate pyrophosphate decarboxylase gene (ERG19) and isopentenyl pyrophosphate isomerase gene (IDI1). The DNA fragment thermal denaturation assembly method has been published in relevant international journals by our laboratory, which is a mature molecular operation method (PloS one 2012doi:10.1371 / journal.pone.0030267.g001).

[0057] The pTrc-low vector construction process is as follows:

[0058]Using the commercialized plasmid pTrcHis2B plasmid (purchased from Invitrogen) and the Saccharomyces cerevisiae...

Embodiment 3

[0068] Embodiment 3 uses glycerol as raw material synthesis gamma-terpinene

[0069] 1. Fermentation of γ-terpinene

[0070] Plasmid transformation: pipette 2 μL of plasmids pHW2 and pTrc-low into Escherichia coli competent (E. coli BL21(DE3)) that is still in a frozen state, and place in an ice bath for 10-30 minutes; then heat shock in a water bath at 42°C for 60- After 90 seconds, put it in an ice bath and let it rest for 1-3 minutes; add 400 μL of LB medium, and activate it on a shaker at 37 °C and 180 rpm for 1 hour; draw 100 μL of bacterial liquid and spread it evenly on the LB solid plate containing chloramphenicol and ampicillin, Cultivate at 37°C for 12 hours, pick a single clone and inoculate it into a culture flask for culture.

[0071] Medium: 20g / L glycerol, 5g / L yeast extract, 1.5g / L MgSO 4 , 100 μL of trace elements, 100 μL of antibiotics, and 1 mL of bacterial solution were placed in a shaker at 37°C and 180 rpm for shaking culture.

[0072] The above-mentio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com