Efficient-recycling chemical-fiber textile wastewater treatment system

A technology of textile wastewater and treatment system, which is applied in textile industrial wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the problems of short fiber collection and inability to separate sludge-like pollutants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

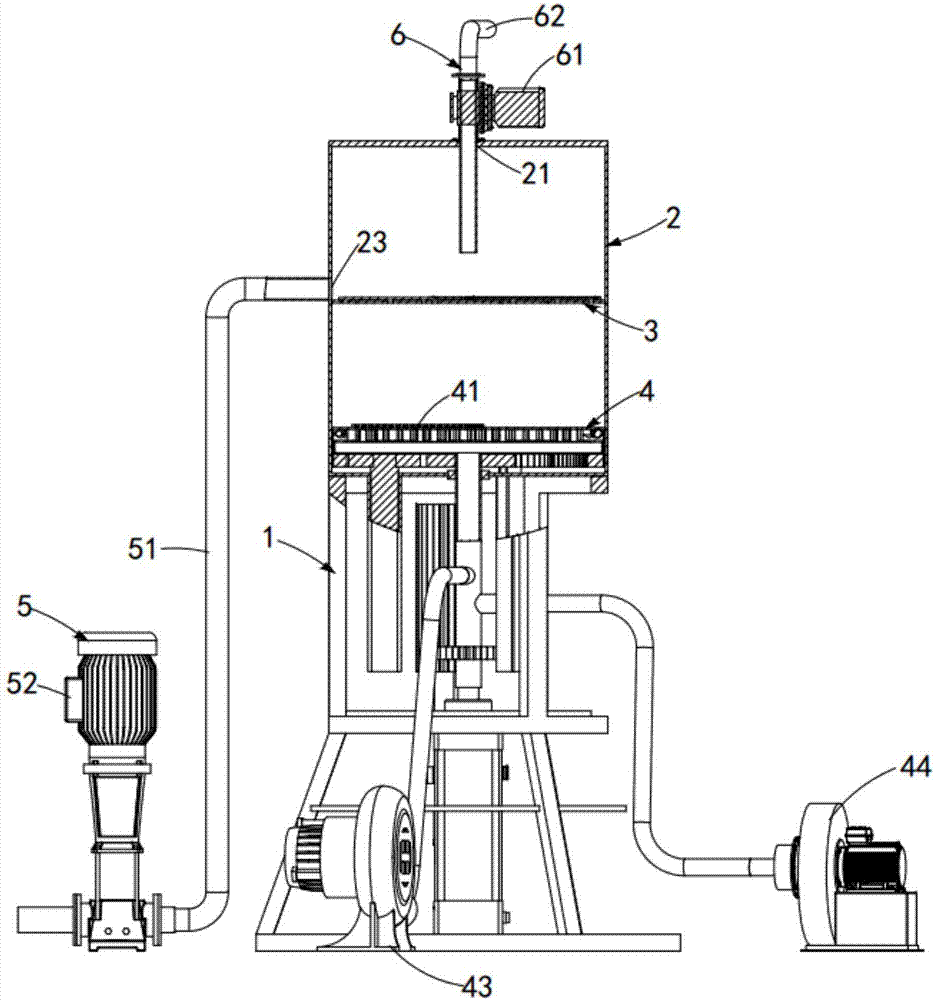

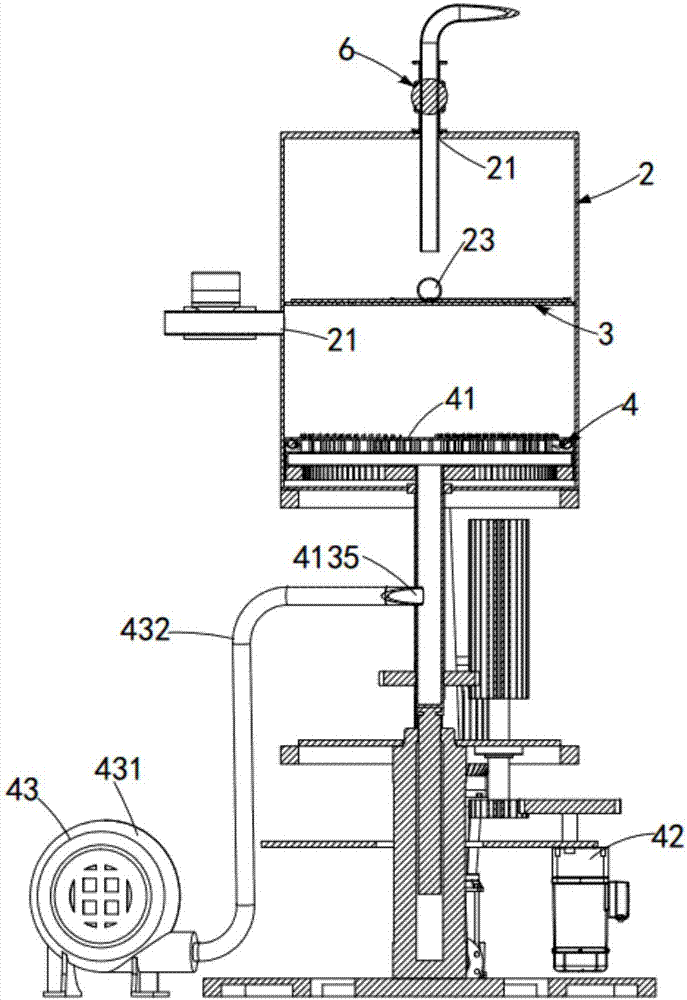

[0065] like figure 1 and figure 2 As shown, an efficient recycling chemical fiber textile wastewater treatment system includes a frame 1, and also includes:

[0066] Compression barrel 2, the compression barrel 2 is fixedly arranged on the upper part of the frame 1, it is cylindrical, and the top is provided with a water outlet 21, the middle of the side wall of the compression barrel 2 is provided with a water inlet 22 and The sludge outlet 23, the water inlet 22 is located below the sludge outlet 23;

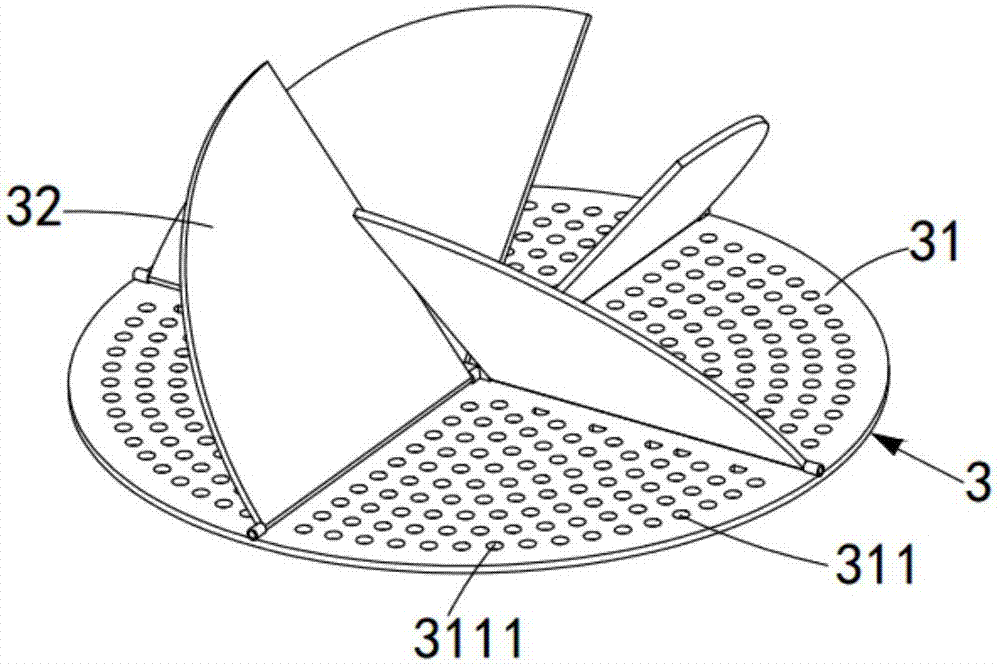

[0067] Filtering mechanism 3, which is fixedly arranged in the middle of the compression barrel 2, which is located between the sludge outlet 23 and the water inlet 22;

[0068] Compression mechanism 4, the compression mechanism 4 is arranged below the filter mechanism 3, which includes a piston push assembly 41, a rotation assembly 42, a blower assembly 43 and a suction assembly 44, and the upper end of the piston push assembly 41 passes through the The compression barrel...

Embodiment approach

[0087] As a preferred embodiment, the rotating assembly 42 includes:

[0088] like Figure 9 and Figure 10 As shown, the rotating unit 421 is arranged below the compression barrel 2 and is fixedly connected with the frame 1;

[0089] A synchronous rotation unit 422, the synchronous rotation unit 422 is located in the compression barrel 2, and is arranged below the piston 412.

[0090] like Figure 9 shown, wherein, the rotating unit 421 includes:

[0091] A rotating motor 4211, the rotating motor 4211 is arranged on one side of the pushing cylinder 411, which is fixedly connected with the frame 1, and a driving gear 4212 is sleeved on the motor shaft;

[0092] A rotating shaft 4213, the rotating shaft 4213 is arranged on one side of the rotating motor 4211, it is rotatably arranged on the frame 1, and a driven gear 4214 is arranged at its end, and the driven gear 4214 is connected with the driving gear 4214. The gears 4212 are engaged, and the upper end of the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com