Linear tin phosphide compound and preparation method thereof

A technology of tin phosphide and compound, applied in the field of preparation of linear tin phosphide compound, can solve the problems of low yield, short reaction time required for phosphide yield, complicated process, etc., so as to improve the yield and shorten the The effect of reducing production time and activation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The synthesis of embodiment 1 linear tin phosphide

[0029] (1) Prepare the ball milling powder according to the mass ratio of tin powder and phosphorus powder at 2:1, prepare the corresponding grams of aluminum powder according to 1 / 10 of the total mass of the two, put the three kinds of powder into the stainless steel ball milling tank, and The ball-to-material ratio was set at 10:1. Vacuum the ball mill tank and inject nitrogen protective gas. This process is repeated three times to ensure that the atmosphere in the ball mill tank is well protected.

[0030] (2) Fix the ball mill jar on the high-energy ball mill, set its rotational speed at 280rpm, and ball milling time at 30h. During the ball milling process, the machine was stopped for 10 minutes every 30 minutes of ball milling. The ball mill product is taken out, and the powder is collected after passing through a 200-mesh sieve.

[0031] (3) Put the obtained powder into a vacuum tube furnace for calcination, ...

Embodiment 2

[0032] The synthesis of embodiment 2 linear tin phosphide

[0033] (1) Prepare the ball milling powder according to the mass ratio of tin powder and phosphorus powder at 5:1, and prepare the corresponding grams of aluminum powder according to 1 / 30 of the total mass of the two, and put the three kinds of powder into a stainless steel ball milling tank. This ball to material ratio was set at 15:1. Vacuum the ball mill tank and inject nitrogen protective gas. This process is repeated three times to ensure that the atmosphere in the ball mill tank is well protected.

[0034] (2) Fix the ball mill jar on the high-energy ball mill, set its rotation speed to 400rpm, and ball milling time to 20h. During the ball milling process, the machine was stopped for 10 minutes every 30 minutes of ball milling. The ball mill product is taken out, and the powder is collected after passing through a 200-mesh sieve.

[0035] (3) The obtained powder is put into a vacuum tube furnace for calcinati...

Embodiment 3

[0038] Example 3 Form of tin phosphide

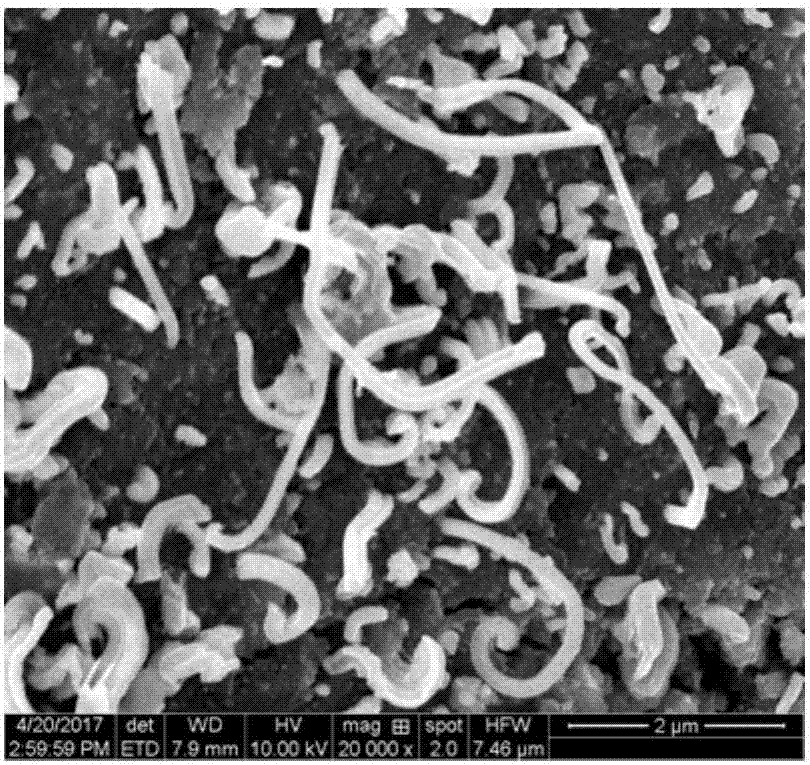

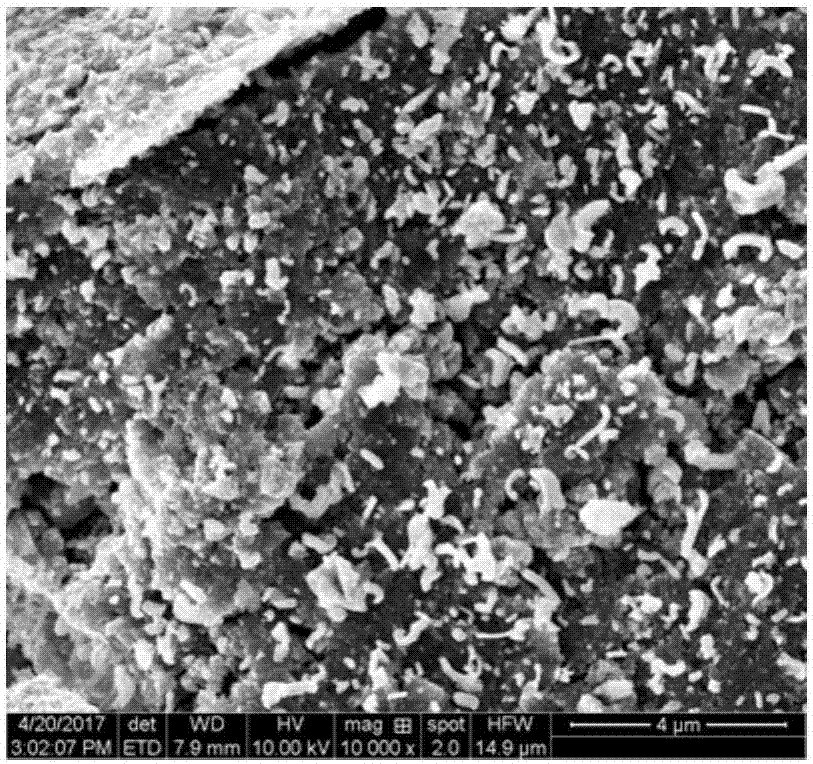

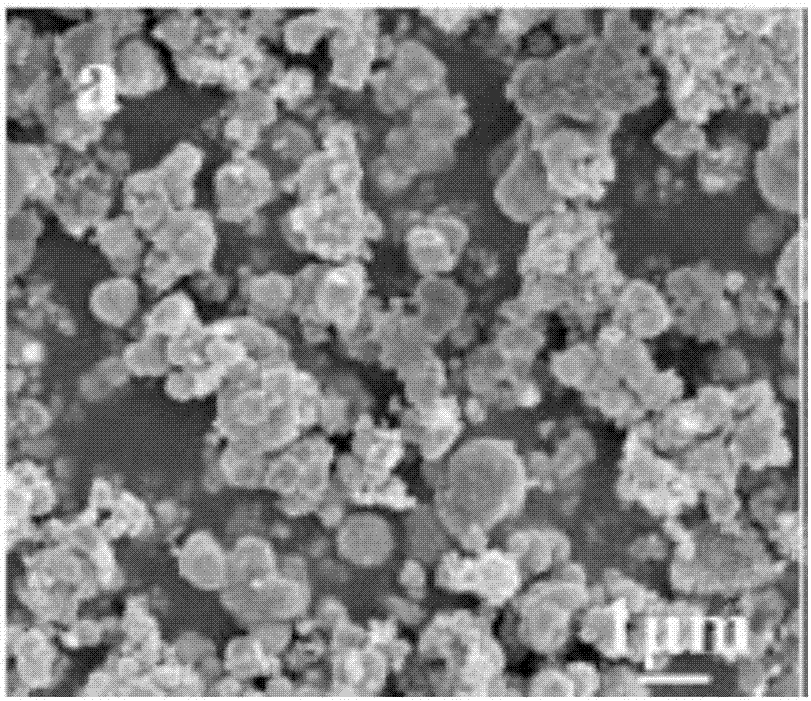

[0039] The sample obtained in embodiment 1, embodiment 2 and comparative example 1 is carried out scanning electron microscope observation, and photo is as Figure 1-3 Shown: The powder particles of S1 are covered with Sn with a length ranging from 0.31 μm to 10.65 μm and a width ranging from 190.3 nm to 305.7 nm. 4 P 3 Line; the powder particles of S2 are covered with Sn with a length ranging from 0.17 μm to 1.51 μm and a width ranging from 88.5nm to 195.7nm 4 P 3 Line; the powder particles of C1 are nearly spherical particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com