Microfluidic MEMS chip packaging method

A technology of chip packaging and microfluidic control, applied in the direction of microstructure devices, manufacturing microstructure devices, processing microstructure devices, etc., can solve the problems of unguaranteed quality, long production cycle, high cost, etc., to shorten the production cycle and improve the quality of finished products The effect of increasing the efficiency and improving the bonding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

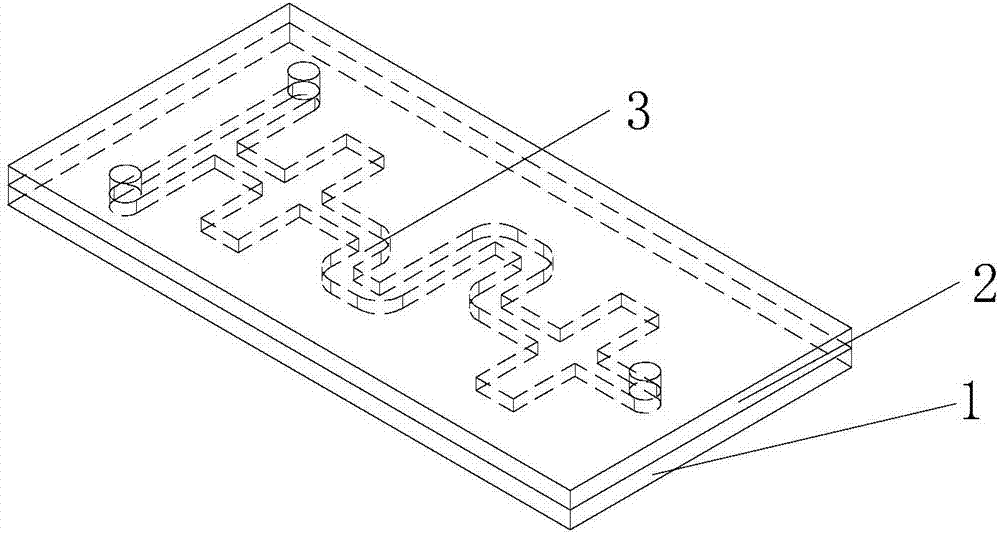

[0029] The microfluidic MEMS chip packaging method of this embodiment is used to package the upper substrate 2 with a microfluidic channel structure and the lower substrate 1 stacked and connected to the upper substrate 2 to obtain a microfluidic MEMS chip (see figure 1 ). The method includes the following steps:

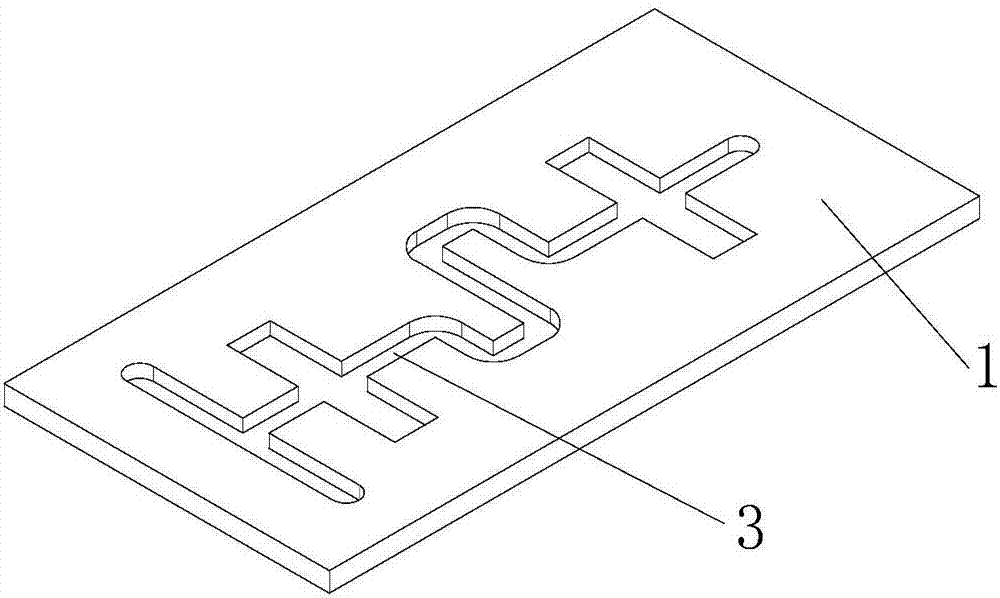

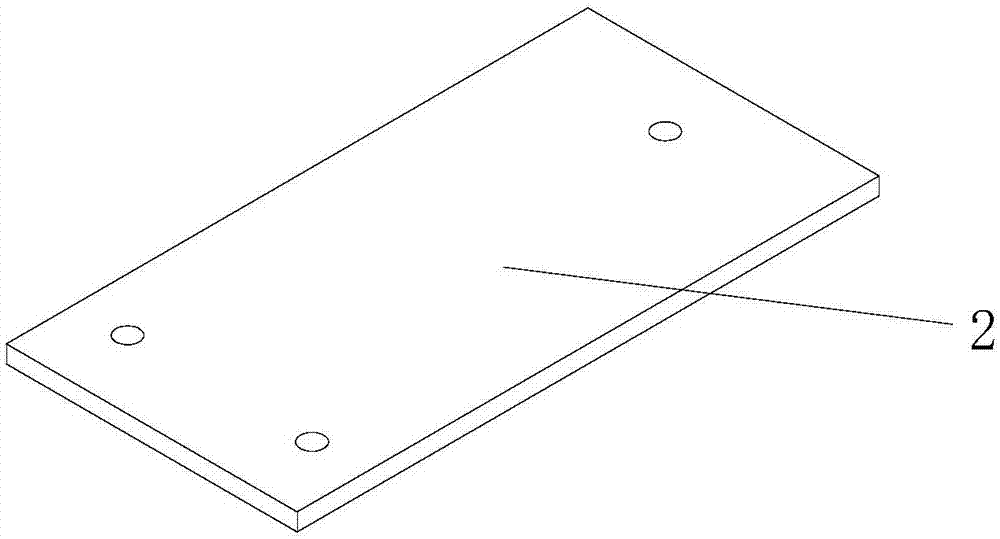

[0030] The first step is to prepare the lower substrate 1 (the lower substrate such as figure 2 shown)——Use the coating method (magnetron sputtering, evaporation or electroplating method) to coat a layer of metal film with a thickness of 200±50nm (preferably 200nm) on the upper surface of the lower substrate 1 made of glass, and use the MEMS process to coat the lower substrate 1 The micro-channel 3 is made on the metal film, and the pattern of the micro-channel 3 is designed according to the customer's requirements. The method for making the micro-flow channel 3 is as follows: after coating a metal masking material with a thickness of 2000 angstroms on the metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com