Lightweight fiber-reinforced phenolic sandwich board and preparation method thereof

A light-weight fiber and fiber-reinforced technology is applied in the field of fiber-reinforced phenolic sandwich panels and their preparation, which can solve the problems of low foam strength on the bonding surface, small bonding area, low epoxy resin adhesive toughness and low flame retardant performance, etc. Achieve the effect of increasing strength and stiffness, high strength retention, good strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0046] See figure 1 , The lightweight fiber-reinforced phenolic sandwich panel in this embodiment consists of two surface layers 2 and a core material layer 1 between the two surface layers 2 .

[0047] The core layer 1 is a fiber-reinforced phenolic lightweight foam layer with a density of 100-400kg / m 3 , the thickness is 4mm ~ 20mm.

[0048] The phenolic foam is obtained by foaming the phenolic resin in the core material layer 1 . The fiber that strengthens the phenolic foam in the core layer 1 is glass fiber, aramid fiber, carbon fiber, boron fiber, BN fiber, basalt fiber, polyethylene fiber, polypropylene fiber, polyimide fiber, PEEK fiber, LCP fiber One or a combination of two or more.

[0049] The surface layer 2 is a fiber-reinforced phenolic composite board, the specific gravity of the surface layer 2 is 1.3-2.0, and the thickness is 0.5mm-2mm.

[0050] The surface layer 2 is obtained by curing phenolic resin and fiber fabric. The reinforcing fiber of surface laye...

Embodiment 2)

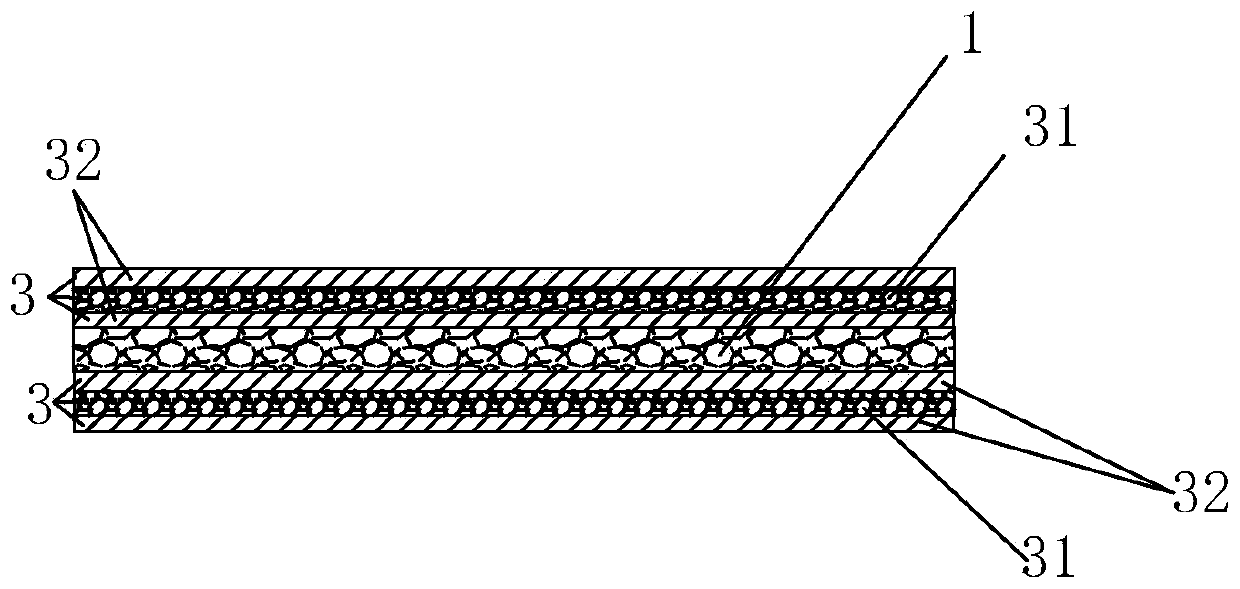

[0071] See figure 2 , The lightweight fiber-reinforced phenolic sandwich plate of this embodiment is composed of two sandwich surface layers 3 and a core material layer 1 between the two sandwich surface layers 3 .

[0072] The core layer 1 is a fiber-reinforced phenolic lightweight foam layer with a density of 100-400kg / m 3 , the thickness is 4mm ~ 20mm.

[0073] The phenolic foam is obtained by foaming the phenolic resin in the core material layer 1 . The fiber that strengthens the phenolic foam in the core layer 1 is glass fiber, aramid fiber, carbon fiber, boron fiber, BN fiber, basalt fiber, polyethylene fiber, polypropylene fiber, polyimide fiber, PEEK fiber, LCP fiber One or a combination of two or more.

[0074] The sandwich surface layer 3 is composed of a sandwich layer 31 and surface layer plates 32 on both sides thereof.

[0075] The sandwich layer 31 is a fiber-reinforced phenolic heavy foam layer with a density of 400-1500kg / m 3 , the thickness is 2mm ~ 4mm. ...

Embodiment 3

[0107] (Example 3, the preparation method of sandwich plate)

[0108] What this example prepares is the lightweight fiber-reinforced phenolic sandwich plate of Example 1, and the rest of the preparation method is the same as that of Example 1, except that:

[0109] Step ② When preparing the foamed film to form the core material layer 1, mix 100 parts of foamable phenolic resin, 3 parts of surfactant, 8 parts of toughening agent, 5 parts of foaming agent, and 6 parts of curing agent, and mix the mixture Pour the material into a kneader, then add chopped fibers into the kneader, knead evenly, put it into a tablet machine to make a 1-8mm thin slice, the thin slice is a foamed film, and the surface is covered with an isolation film for use.

[0110] When preparing the foamed and cured composite in step ③, first remove the isolation film on both sides of the foamed film obtained in step ②, and then compound the prepreg tape obtained in step ① on both sides to obtain a foamed cured ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com