Horizontal reciprocating abrasive grain current polisher mechanical structure

A mechanical structure, abrasive flow technology, applied in grinding/polishing equipment, surface polishing machine tools, abrasive jet machine tools, etc., can solve the problems such as the inability of the abrasive to reach the barrel, weak structural stability, and reduced processing efficiency. To achieve the effect of easy debugging and maintenance, simple and compact structure, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

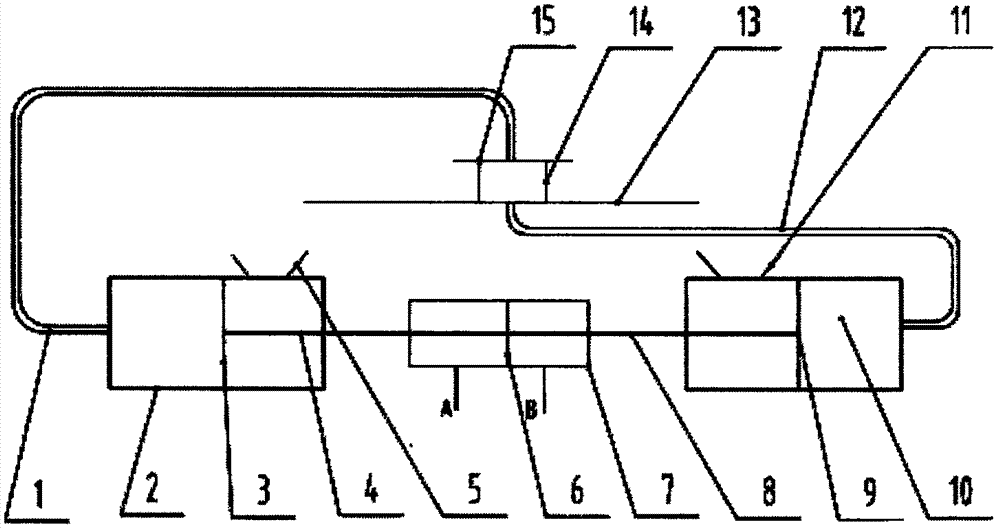

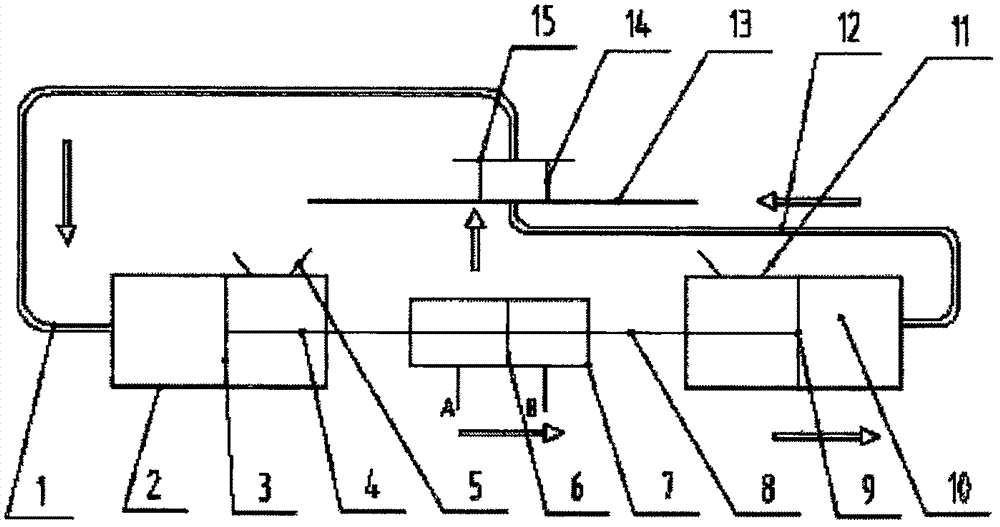

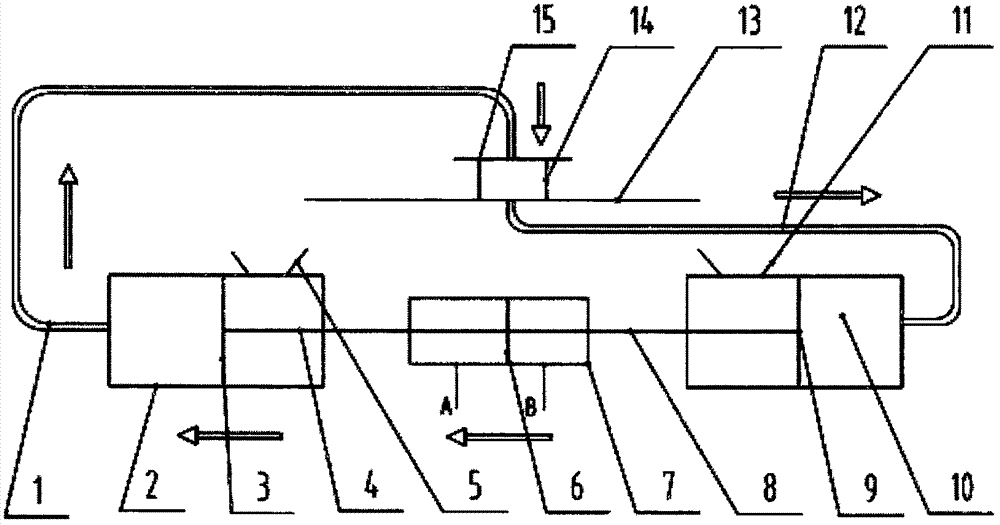

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0016] like figure 1 As shown, the mechanical structure of a horizontal reciprocating abrasive flow polishing machine according to the present invention includes an abrasive movement circulation device, a power device, a working platform, and a fixture. The abrasive motion circulation device described therein is divided into a left abrasive motion device, a right abrasive motion device, and an abrasive flow pipe; the left abrasive motion device includes a barrel 2, a hopper 5, and a pressing plate 3; the right abrasive motion flow device includes a barrel 10 and a hopper 5 , pressing plate 9. Described power unit is provided by double output rod hydraulic cylinder 7, comprises left output rod 4, right output rod 8, piston 6 and oil port A, B etc.; Workpiece 14 etc.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com