Preparing method for thorniness gold nanoparticles

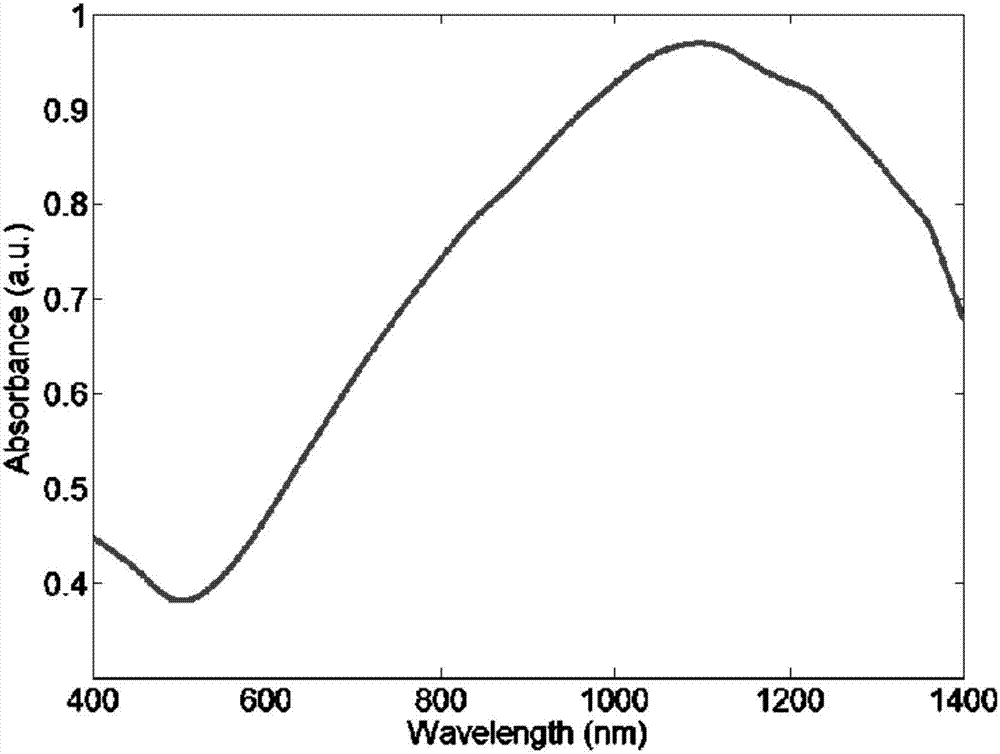

A gold nanoparticle and gold source technology, applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve the problems of low yield, irregular height of prickly gold nanoparticles, few thorns of spherical particles, etc. The effect of narrow size distribution, simple synthesis conditions, and obvious absorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of prickly gold nanoparticles, comprising the steps of:

[0029] (1) Add 5 mL of Triton X-100 with a concentration of 130 mmol / L into a 20 mL glass bottle washed with aqua regia;

[0030] (2) Add 125 μL of silver nitrate solution with a concentration of 4 mmol / L into the glass bottle and shake clockwise for 10 seconds;

[0031] (3) Add 25 μL of chloroauric acid solution with a concentration of 100 mmol / L into the glass bottle and shake clockwise for 10 seconds;

[0032] (4) Add 85 μL of ascorbic acid solution with a concentration of 80 mmol / L into the glass bottle and shake clockwise for 3 seconds;

[0033] (5) The solution was left to stand for 1.5 hours at a temperature of 20° C. to obtain a spiny gold nanoparticle dispersion;

[0034] (6) Then add the cetyltrimethylammonium bromide solution equal to the volume of 100mmol / L of the prickly gold nanoparticle dispersion, stir for 2 hours, centrifuge and be dissolved in deionized water again, the ce...

Embodiment 2

[0038] A preparation method of prickly gold nanoparticles, comprising the steps of:

[0039] (1) Add 5 mL of Triton X-100 with a concentration of 130 mmol / L into a 20 mL glass bottle washed with aqua regia;

[0040] (2) Add 100 μL of silver nitrate solution with a concentration of 4 mmol / L into the glass bottle and shake clockwise for 10 seconds;

[0041] (3) Add 25 μL of chloroauric acid solution with a concentration of 100 mmol / L into the glass bottle and shake clockwise for 10 seconds;

[0042](4) Add 50 μL of ascorbic acid solution with a concentration of 80 mmol / L into the glass bottle and shake clockwise for 5 seconds;

[0043] (5) The solution was left to stand for 1 hour at a temperature of 30° C. to obtain a spiny gold nanoparticle dispersion;

[0044] (6) Then add the cetyltrimethylammonium bromide solution equal to the volume of the prickly gold nanoparticle dispersion of 10mmol / L, stir for 1.5 hours, centrifuge and be dissolved in deionized water again, the centr...

Embodiment 3

[0047] A preparation method of prickly gold nanoparticles, comprising the steps of:

[0048] (1) Add 5 mL of Triton X-100 with a concentration of 130 mmol / L into a 20 mL glass bottle washed with aqua regia;

[0049] (2) Add 300 μL of silver nitrate solution with a concentration of 4 mmol / L into the glass bottle and shake clockwise for 15 seconds;

[0050] (3) Add 25 μL of chloroauric acid solution with a concentration of 100 mmol / L into the glass bottle and shake clockwise for 15 seconds;

[0051] (4) Add 300 μL of ascorbic acid solution with a concentration of 80 mmol / L into the glass bottle and shake clockwise for 3 seconds;

[0052] (5) The solution was left to stand for 2.5 hours at a temperature of 15° C. to obtain a spiny gold nanoparticle dispersion;

[0053] (6) Then add the hexadecyltrimethylammonium bromide solution of 200mmol / L equal volume with spiny gold nanoparticle dispersion liquid, after stirring for 2.5 hours, centrifuge and be dissolved in deionized water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com