Paperless ultra-thin and super-soft double-spunlace core body

A spunlace, ultra-thin technology, applied in medical science, bandages, etc., can solve the problems of inability to improve product quality, poor softness, and product thickness, etc., to improve product quality, reduce the amount of glue sprayed, and improve grades. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

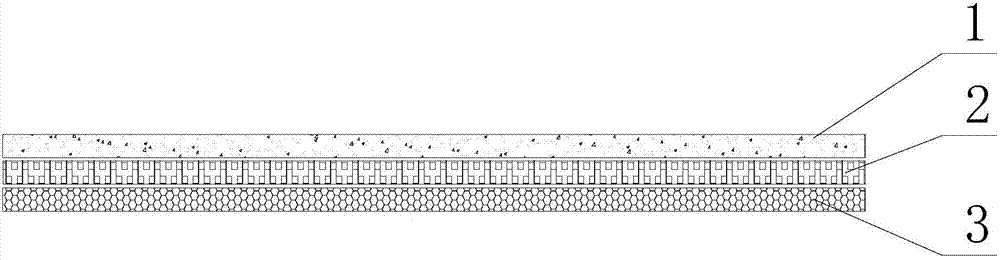

[0018] refer to figure 1 , paperless ultra-thin ultra-soft double spunlace core body, including spunlace cloth layer 1, bulky cloth layer 2 and lower spunlace layer 3 arranged in sequence from top to bottom, the upper surface of the bulky cloth layer 2 and The lower surface is sprayed with a viscose layer, the viscose layer of the bulky cloth layer 2 is sprinkled with some water absorption factors, the spunlace cloth layer 1 is bonded to the upper surface of the bulky cloth layer 2, and the lower spunlace layer 3 is bonded to the The lower surface of the loose cloth layer 2.

[0019] The thickness of the lower spunlace layer 3 is 35-40g / m 2 , is thinner than the dust-free paper used in the prior art, and has better water diversion and water absorption. The processing technology of the lower spunlaced layer 3 is: first loosen, then card, then lay the net, then card again, and lay again The net is then spunlace, and finally dried to obtain a non-woven fabric with a spunlace la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com