Semiconductor structure and manufacturing method thereof

A manufacturing method and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, transistors, etc., can solve the problems of semiconductor device electrical performance degradation and achieve the effect of optimizing electrical performance and avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

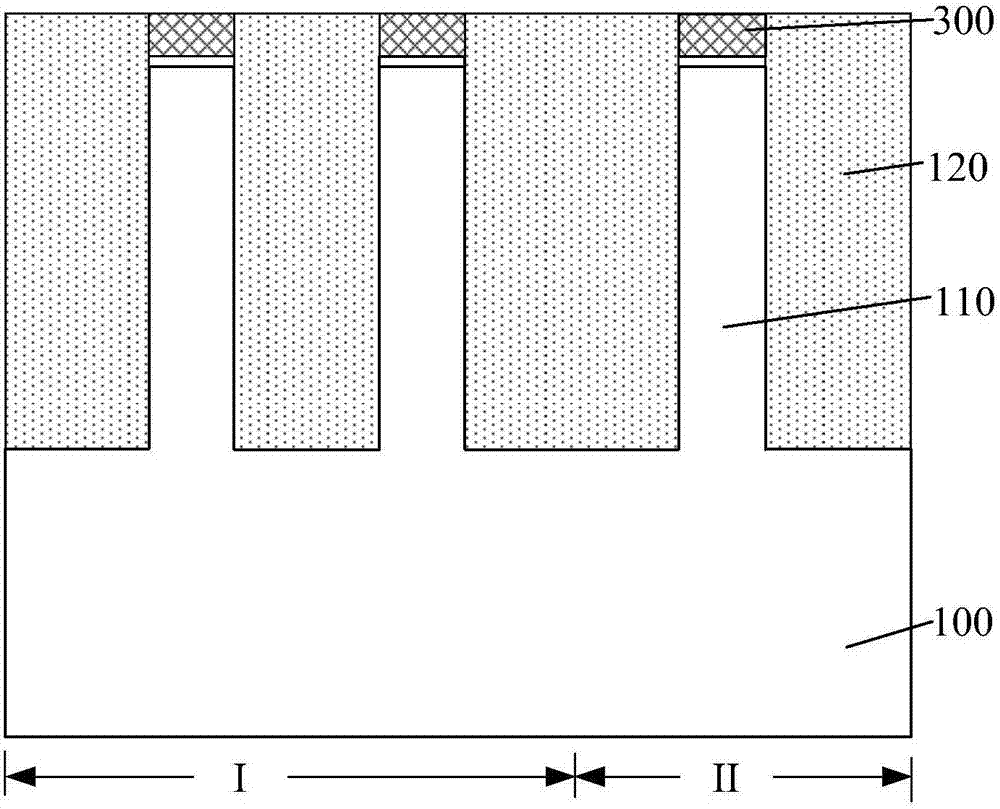

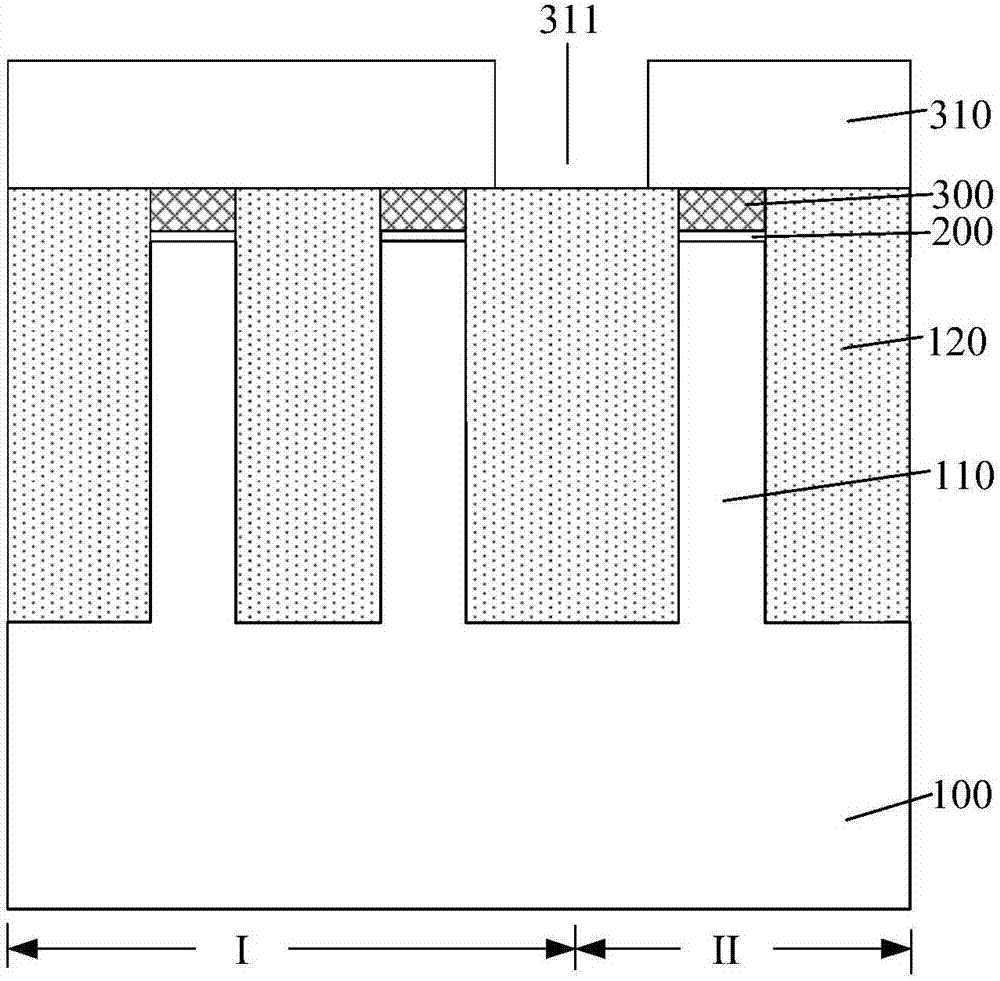

[0031] It can be known from the background technology that the shallow trench isolation structure of the prior art is likely to cause a reduction in the electrical performance of the semiconductor device, and the reason is analyzed in combination with the manufacturing method of the prior art semiconductor structure. Combined reference Figure 1 to Figure 6 , Shows a schematic structural diagram corresponding to each step in an embodiment of a manufacturing method of a prior art semiconductor structure.

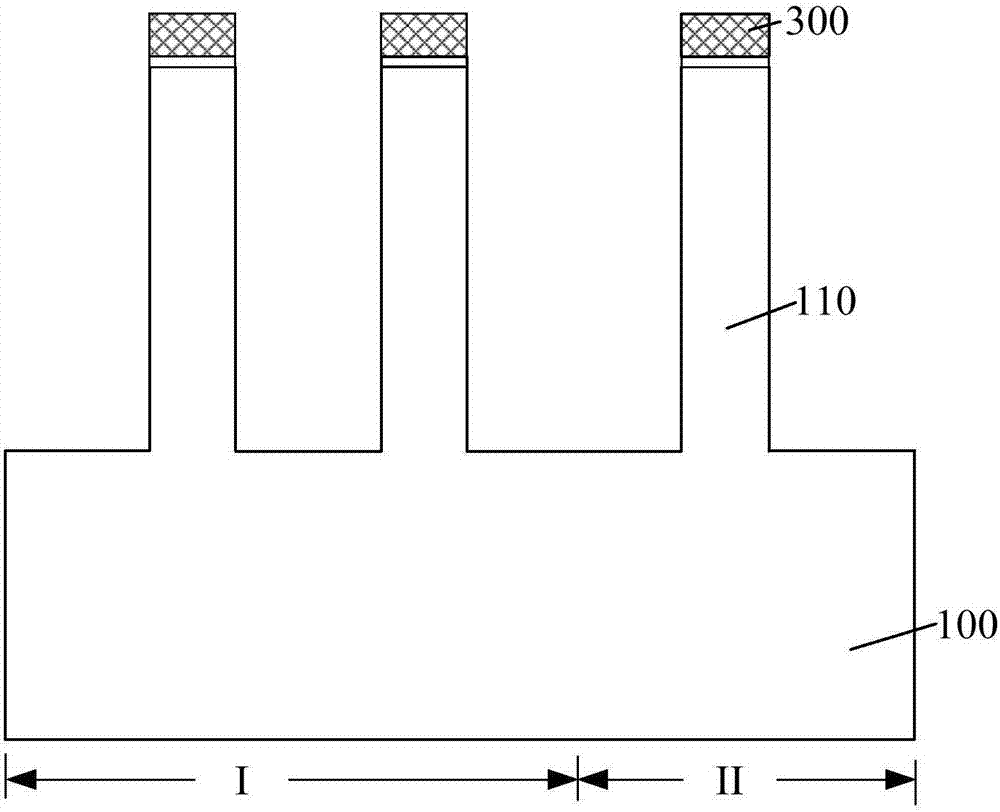

[0032] reference figure 1 , Provide a base (not labeled), the base includes a substrate 100 and a fin 110 protruding from the substrate 100, the substrate includes a first area I and a second area II.

[0033] In this embodiment, the substrate is used to form SRAM, the first region I is used to form pull-down (PD, Pull Down) transistors or pass gate (PG, Pass Gate) transistors, and the second region II is used to form Pull up (PU, Pull Up) transistor.

[0034] It should be noted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com