Oil and gas lubricating spacer bush assembly

An oil-air lubrication and spacer technology, which is applied to bearing components, shafts and bearings, bearing cooling, etc., can solve problems such as poor lubrication and cooling effects, uneven oil injection, etc., to improve oil and gas collection capabilities, improve work efficiency, The effect of improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

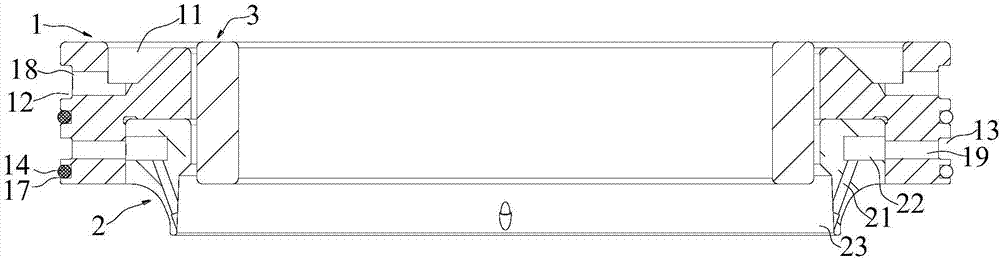

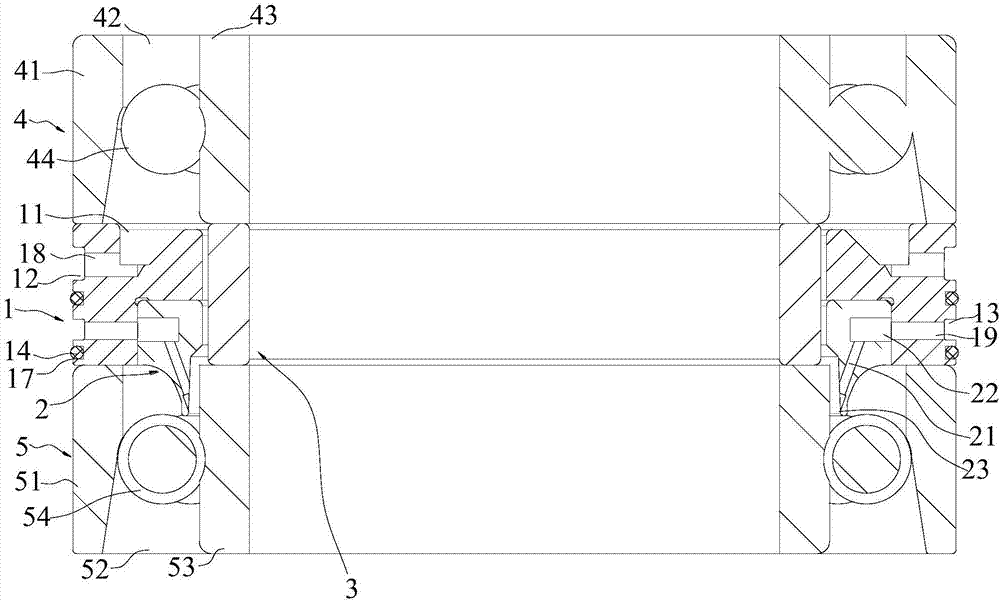

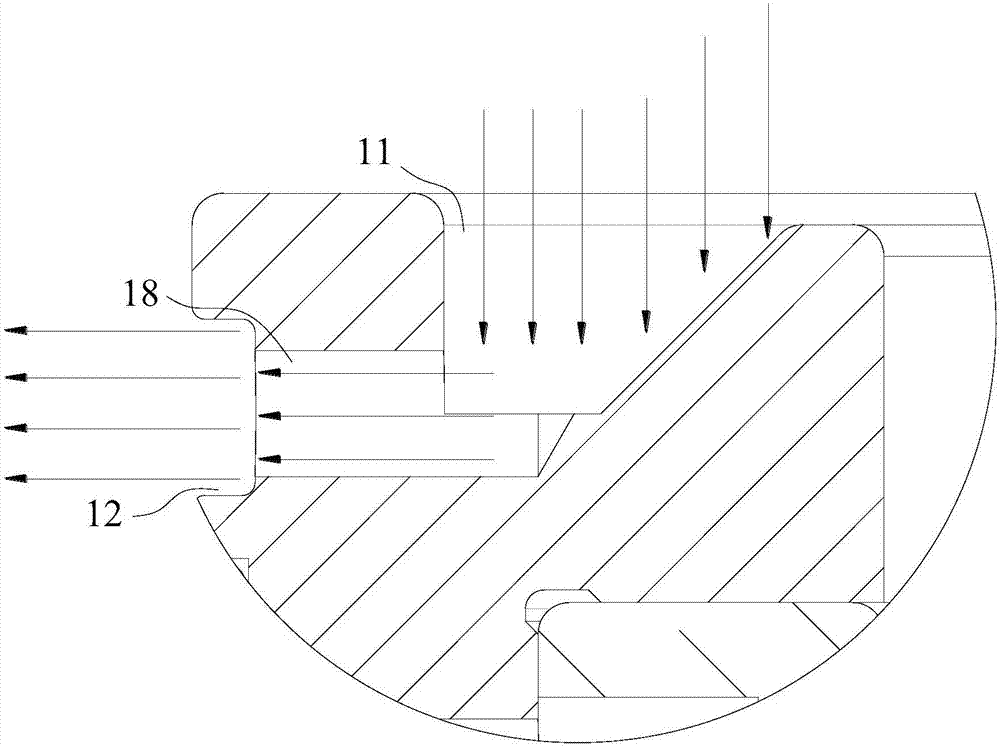

[0030] Such as figure 1 , 2 The shown oil-air lubrication spacer assembly includes an outer spacer 1 for receiving the upper bearing outer ring 41 and the lower bearing outer ring 51, an oil guide sleeve 2 for supplying oil to the lower bearing 5, and an oil guide sleeve for rolling with the lower bearing. The oil guide channel 21 connected with the channel 52, the oil and gas collection ring groove 11 for recovering the oil and gas of the upper bearing 4, the oil return ring groove 12 for connecting the inlet of the oil and gas buffer tank, and the oil inlet ring groove 13 for connecting the outlet of the oil and gas buffer tank 1. The sealing ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com