Grouting method for concrete raft foundation construction joint

A technology for construction joints and concrete, which is applied in infrastructure projects, artificial islands, water conservancy projects, etc., can solve the problems of water leakage, labor and time-consuming, and difficulty in plugging, achieving high cost, convenient plugging, and saving construction period and costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

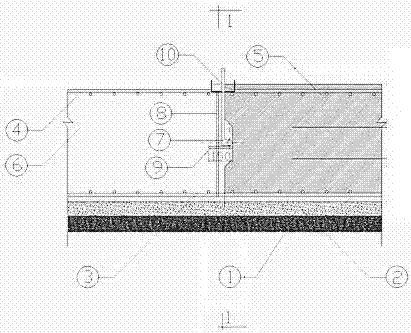

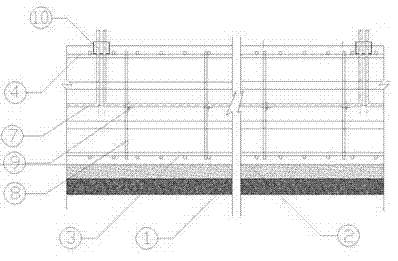

[0025] exist Figure 1-5 Among them, the grouting method at the concrete raft foundation construction joint of the present invention comprises the following construction steps:

[0026] Step 1. On the concrete raft foundation cushion, bind the lower two-way steel bars 3 of the reinforced concrete raft foundation, and bind the upper two-way steel bars 4 of the reinforced concrete raft foundation;

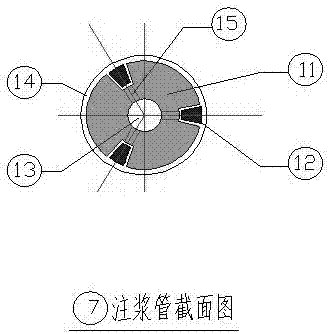

[0027] Step 2, welding the vertical reinforcement 8, burying the grouting pipe in the middle of the reinforced concrete groove, and welding the horizontal reinforcement 9 on the vertical reinforcement 8;

[0028] Step 3, welding the grouting box 10 on the concrete surface of the raft foundation to be consistent with the building elevation, and the lower part of the grouting box 10 is provided with two grouting box holes 16 for the holes of the grouting pipe;

[0029] Step 4: Lay the grouting pipe 7 on the horizontal steel bar 9, and stick it straight to the groove edge of the poured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com