Gas boiler and tail gas cooling and water outlet seal method thereof

A gas-fired boiler and water outlet technology, applied in the field of boilers, can solve the problems of unutilized exhaust heat, leakage of the water outlet, inability to deal with carbon monoxide in the exhaust gas, etc., and achieves the effect of increasing heat, convenient plugging, and increasing heat exchange time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

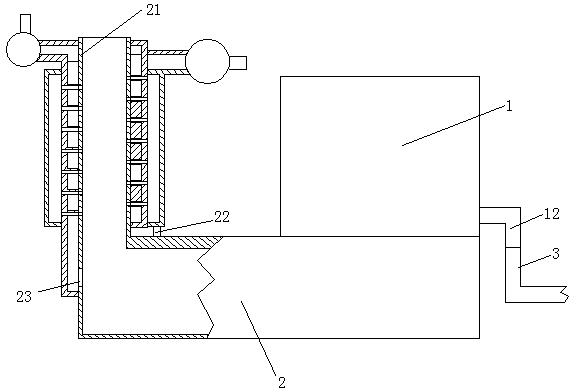

[0027] Embodiment one, see figure 1 and figure 2 , including a water tank 1 and a combustion furnace 2 for heating water in the water tank. The water tank 1 is provided with a water outlet 12 opening downward. The water outlet is sealed and connected with an outlet pipe 3 .

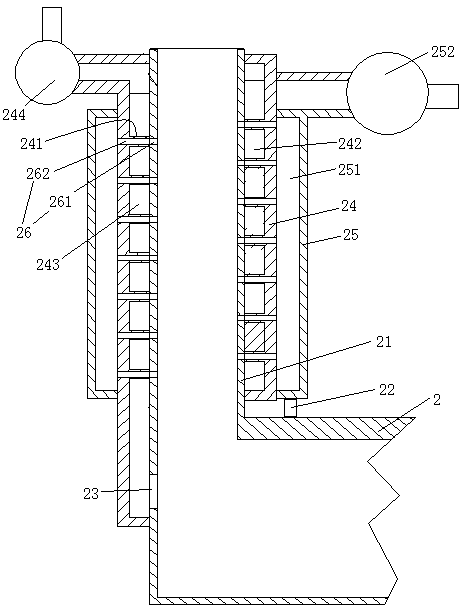

[0028] The combustion furnace 2 is provided with a flue gas discharge pipe 21 , an air inlet 22 and a gas inlet 23 . The outer casing of the flue gas discharge pipe is provided with an inner casing 24 . An outer sleeve 25 is provided on the outer sleeve of the inner sleeve. An inner air chamber 241 is formed between the inner casing and the exhaust gas discharge pipe. The inner air chamber is provided with a spiral piece 242 whose centerline is the centerline of the flue gas discharge pipe. The spiral piece forms a spiral fuel flow channel 243 in the inner air chamber. One end of the gas channel is connected with the gas inlet, and the other end is connected with the outlet of the gas pump 244 . ...

Embodiment 2

[0030] Embodiment two, the difference with embodiment one is:

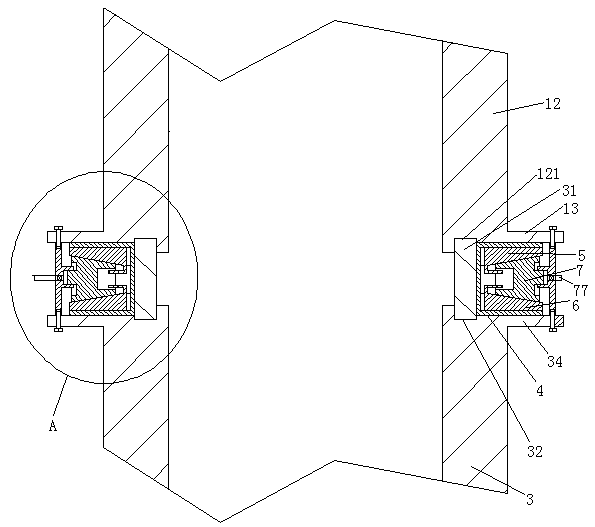

[0031] see image 3 and Figure 4 , also includes a limit ring 31. A water outlet limiting ring groove 121 extending along the circumference of the water outlet is provided on the lower end surface of the water outlet. The upper end surface of the water outlet pipe is provided with a water outlet pipe portion limiting ring groove 32 extending along the circumference of the water outlet pipe. The upper end of the limit ring is set in the limit ring groove of the water outlet part, and the lower end is set in the limit ring groove of the water outlet pipe part. An installation groove 33 extending along the circumference of the water outlet is formed between the water outlet, the limiting ring and the water outlet pipe. A sealing ring 4 is sleeved on the limit ring. The sealing ring includes an upper sealing side wall 41 , a connecting wall 42 and a lower sealing side wall 43 distributed sequentially from top to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com