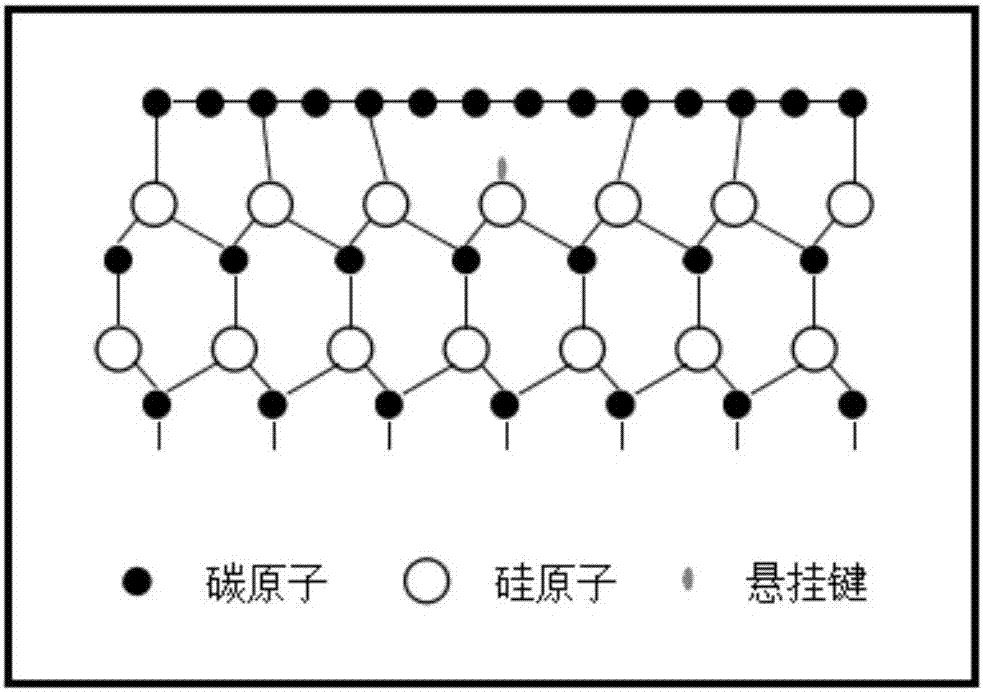

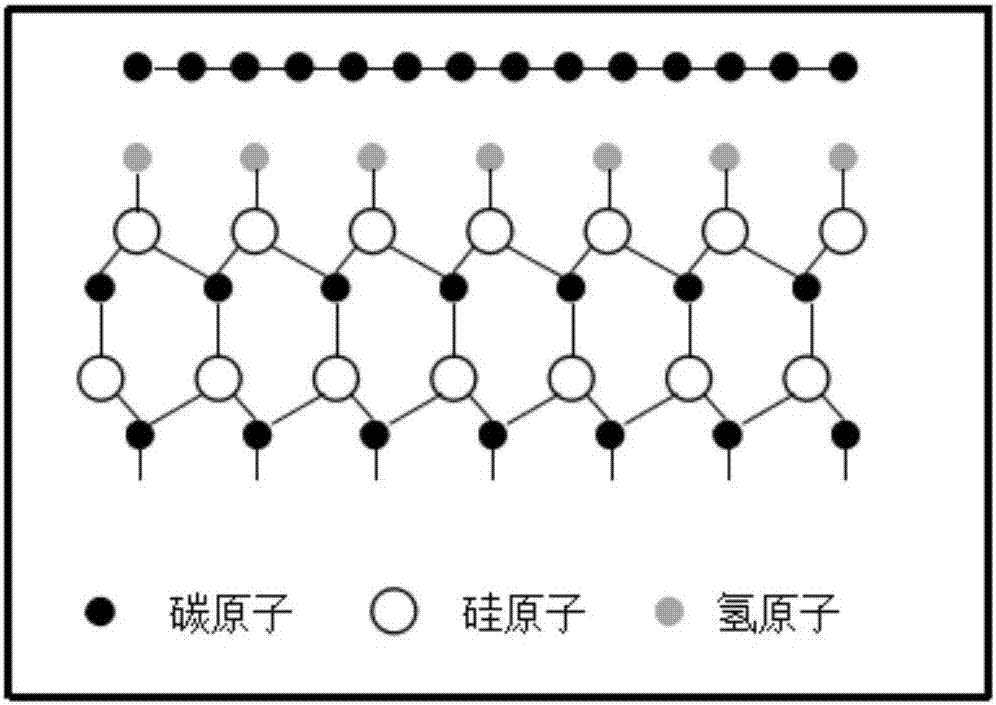

Method for preparing single-layer graphene without buffer layer on SiC substrate

A single-layer graphene, buffer-free technology, applied in the field of single-layer graphene, can solve the problems of many layers of graphene and no single-layer graphene prepared

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing single-layer graphene without a buffer layer on a SiC substrate, comprising the steps of:

[0041] (1) The silicon surface of the 3-inch diameter 4H semi-insulating SiC wafer substrate is chemically mechanically polished (CMP) to make the surface roughness less than 0.5nm, and then standard wet cleaning is performed to remove surface pollutants.

[0042] (2) Put the SiC substrate cleaned in the above step (1) with the silicon side up into the graphite tray in the heating furnace chamber, and vacuumize the furnace chamber until the vacuum degree reaches 10 -2 Pa.

[0043] (3) The temperature was raised to 1600°C, hydrogen gas was introduced into the furnace cavity, and the pressure was controlled at 800mbar, and hydrogen etching was performed on the SiC substrate sample to form a regular step morphology on the surface of the SiC substrate. The hydrogen etching time is 20min. After the hydrogen etching is completed, a regular step morphology is form...

Embodiment 2

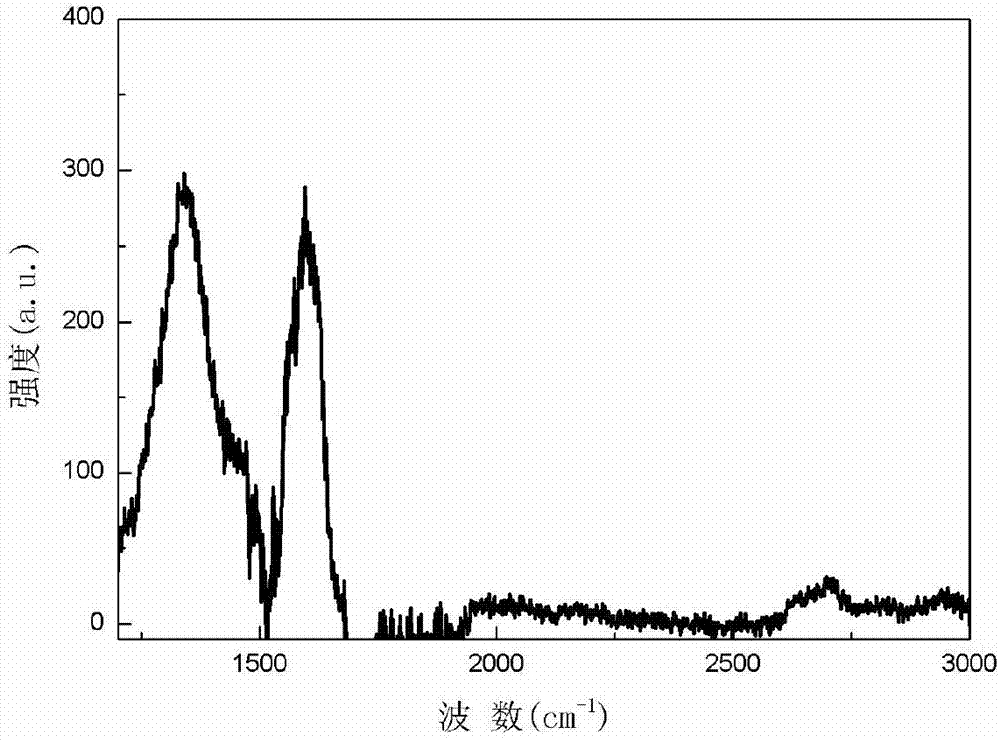

[0048] A method for preparing single-layer graphene without a buffer layer on a SiC substrate, according to the same method for preparing single-layer graphene as in Example 1, except that the hydrogen annealing temperature is 800°C. The obtained sample was tested with a Raman spectrometer, and the results showed that there was no buffer layer, and the SiC substrate was covered with single-layer graphene, and the graphene was of good quality.

Embodiment 3

[0050] A method for preparing single-layer graphene without a buffer layer on a SiC substrate, according to the same method for preparing single-layer graphene as in Example 1, except that the hydrogen annealing temperature is 1200°C. The obtained sample was tested with a Raman spectrometer, and the results showed that there was no buffer layer, and the SiC substrate was covered with single-layer graphene, and the graphene was of good quality.

[0051] Combining the detailed descriptions of the above examples 1-3 with the characterization results of the examples, it can be seen that this method can prepare single-layer graphene without a buffer layer on a SiC substrate, and at a suitable hydrogen annealing temperature, the prepared The resulting single-layer graphene has high quality and good uniformity, which provides a favorable material basis for the subsequent application of graphene radio frequency devices.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com