Composite sub-pixel angle point positioning method based on curvature and gray level

A sub-pixel positioning and curvature angle technology, applied in image enhancement, image analysis, image data processing, etc., can solve problems affecting the reliability of corner points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

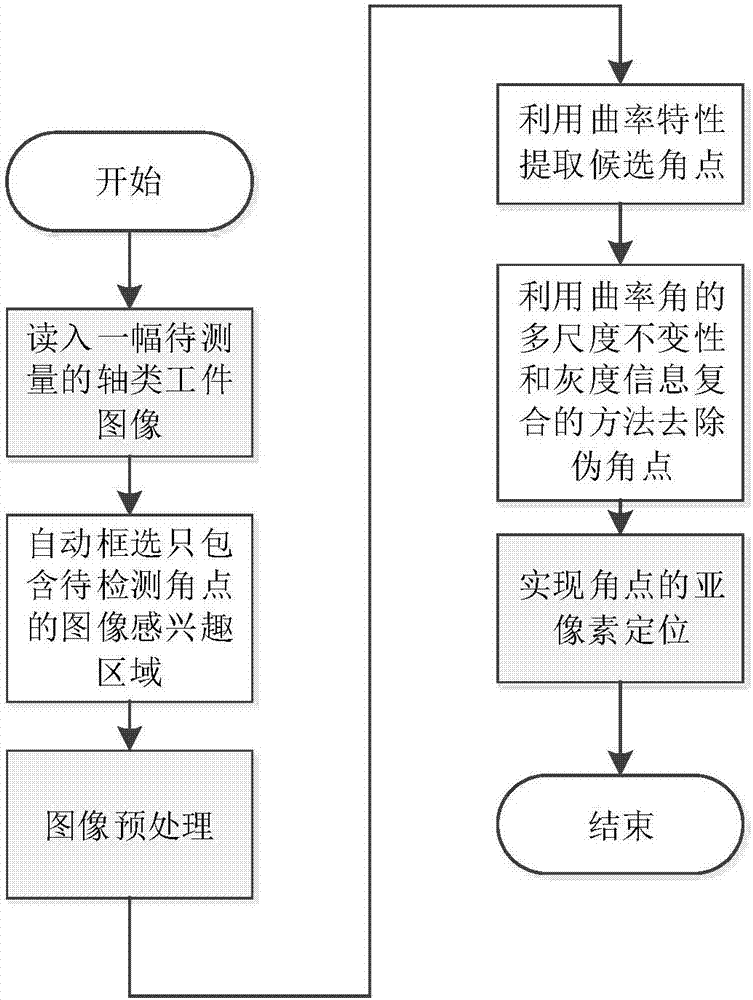

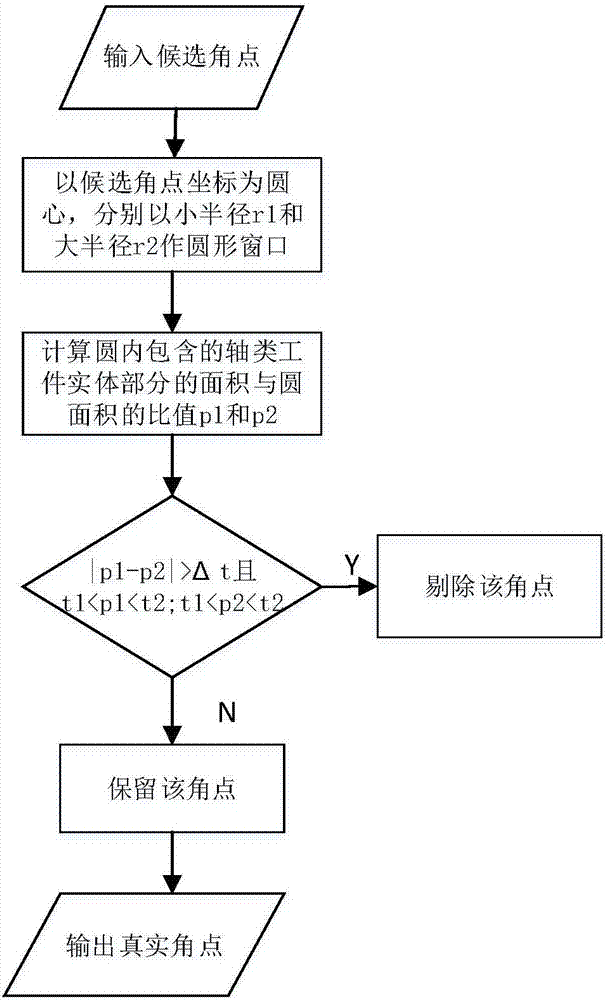

[0035] The purpose of the present invention is to design a method for reliably and accurately extracting corner points in the region of interest for the problem that contour attachments interfere with corner point detection in visual measurement. The process is divided into four parts: image preprocessing, extracting candidate corners points, removal of false corners, sub-pixel positioning, such as figure 1 shown.

[0036] The specific steps are:

[0037] (1) Preprocessing the image area of interest

[0038] (1.1) Firstly, the morphological closed operation is performed on the image to eliminate the burr edges generated during the workpiece processing, and to eliminate some false edges caused by the oil on the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com