Length comparison difference value measurement method without accurate positioning

A measurement method and precise positioning technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of high price of measuring equipment, low measurement accuracy, cumbersome process, etc., achieve simple and feasible measurement method, reduce measurement conditions, The effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

[0019] 1. Definition of standard workpiece length

[0020] like figure 1 As shown, the distance between any two points parallel to the datum plane on the plane is the principle of the plane length.

[0021] 1. Determine a standard workpiece whose length is L0.

[0022] 2. Select two points a and b as required, and the length between the two points is L0.

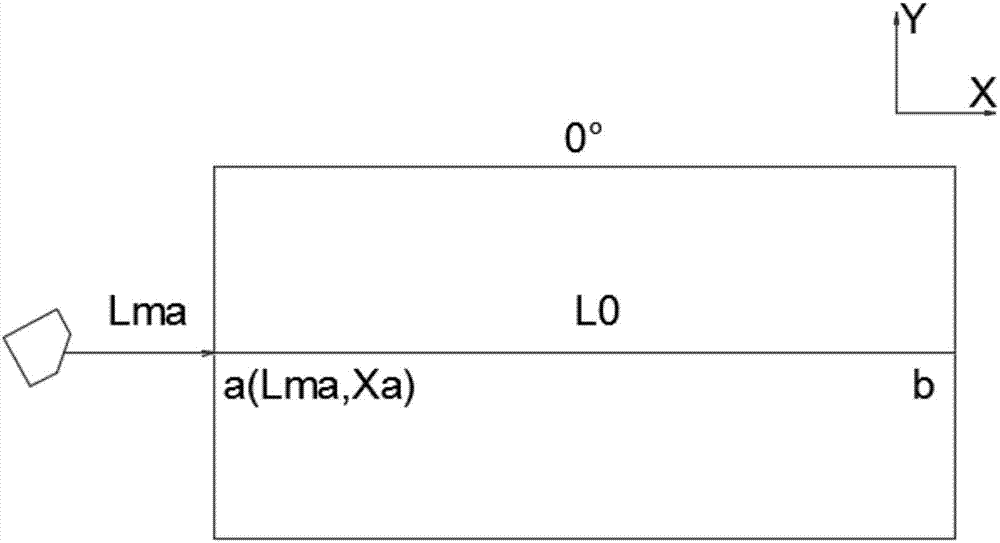

[0023] 3. Moving standard workpieces such as figure 2 , first make the measurement reference plane perpendicular to the measured reference plane, let the laser sensor measure to point a, and obtain a measurement reading Lma. Take the origin of the measuring platform as the coordinate origin to obtain the coordinate value Xa of the X-axis when point a is obtained, that is, point a (Lma, Xa).

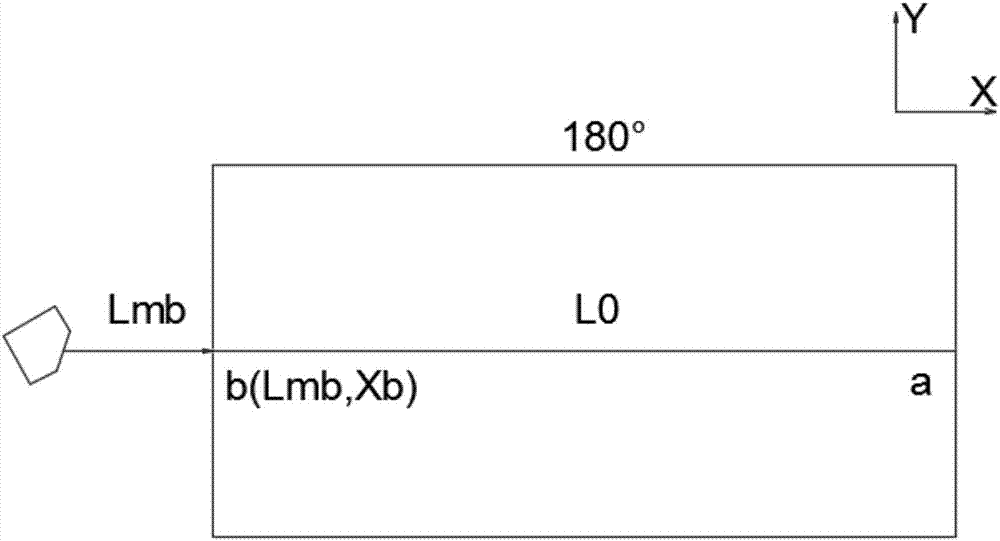

[0024] 4. Move the standard workpiece to rotate 180° such as image 3 , let the laser sensor measure point b, obtain a meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com