Transition metal boride and metal composite target material, coating equipment and application thereof

A transition metal and metal composite technology, which is applied in metal material coating process, sputtering coating, ion implantation coating and other directions, can solve the problem of difficult and precise control of metal content, save installation time, good controllability, Actionable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

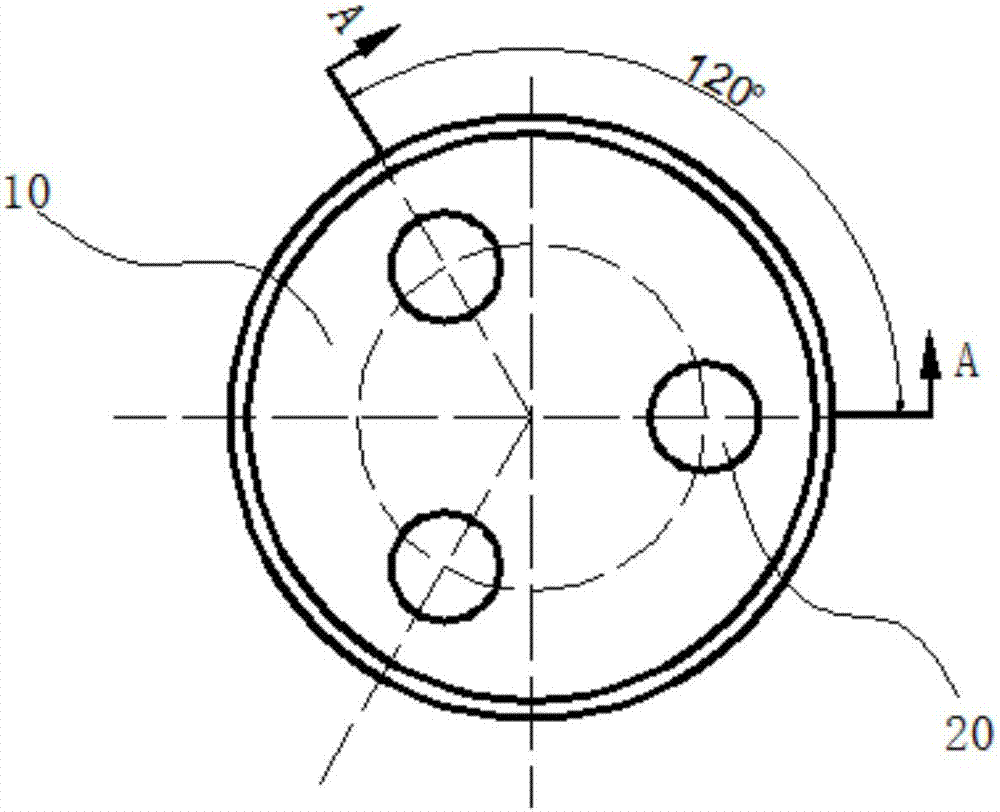

[0034] Such as figure 1 and figure 2 As shown, this embodiment is a transition metal boride-metal composite target, including a transition metal boride substrate 10 and a metal piece 20 fixedly connected to the transition metal boride substrate 10, and the working surface of the transition metal boride substrate 10 It is co-surface with the working surface of the metal part 20 .

[0035] The metal piece 20 and the transition metal boride substrate 10 in the present invention are fixed together, and the working surfaces of the two are coplanar, which ensures that the transition metal boride and the metal can enter the composite coating at the same time. According to the mass ratio of the metal and the transition metal boride in the composite coating, the area ratio of the working surface of the metal piece 20 and the transition metal boride matrix 10 is designed, so as to achieve the purpose of accurately controlling the metal content in the composite coating, and make the tr...

Embodiment 2

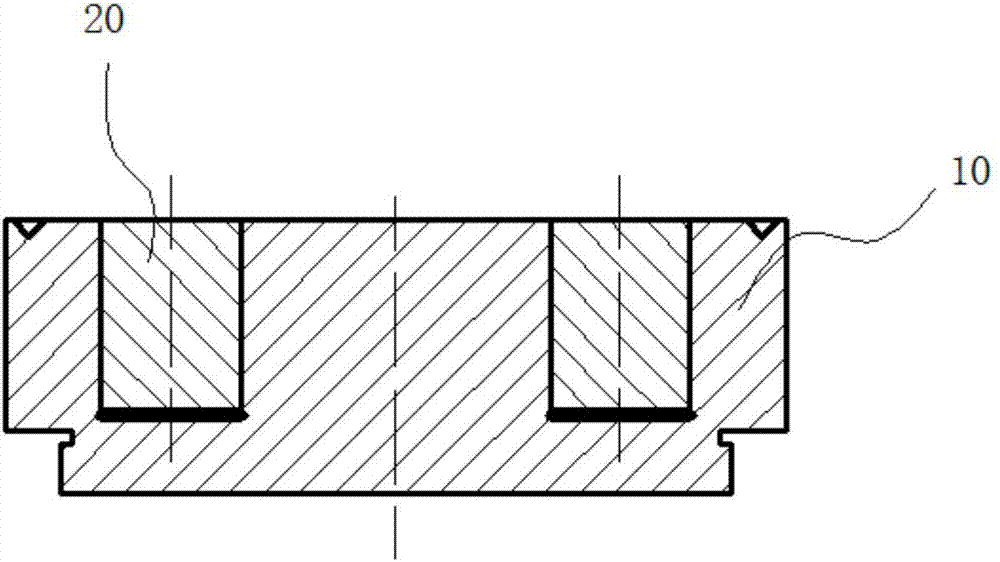

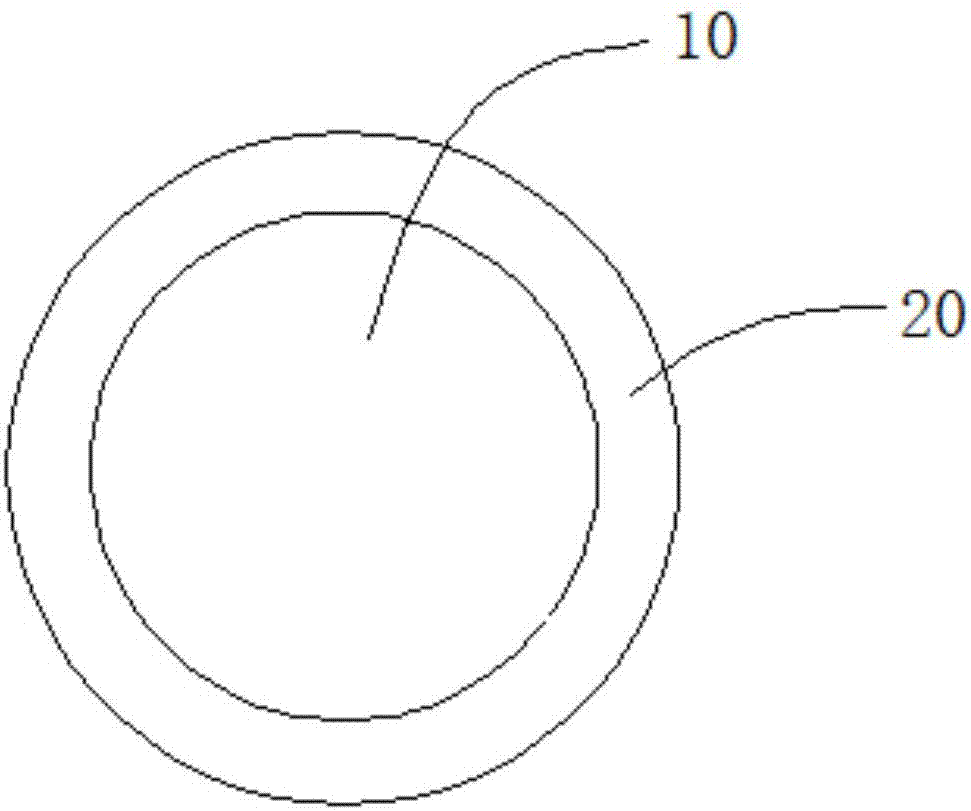

[0047] Such as image 3 As shown, this embodiment is a transition metal boride-metal composite target. The difference from Embodiment 1 is that the metal piece 20 in this embodiment is fixed on the outer peripheral surface of the transition metal boride matrix 10 . All the other are identical with embodiment 1. Specifically, the metal piece 20 is fixedly connected to the transition metal boride substrate 10 by welding, clamping or screwing. Wherein, the metal piece 20 is a ring structure, sheathed on the outer peripheral surface of the transition metal boride matrix 10 , and the inner diameter of the metal piece 20 matches the outer diameter of the transition metal boride collective 10 .

Embodiment 3

[0049] This embodiment is a transition metal boride-metal composite target. The difference from Example 1 is that in this example, the transition metal boride substrate 10 is selected from the hard phase TiB 2 , the metal part 20 is made of Cu metal part 20, and the combination of the two forms TiB 2 -Cu composite target. The atomic content of Cu is 5 at.%.

[0050] TiB in this example 2 -Cu composite target is designed according to the size of the corresponding target installation position in the coating equipment. where TiB 2 - The diameter of the thread size of the Cu composite target is 86mm, the pitch is 1mm, the thread depth is 8mm, the size of the deepest undercut of the thread is 1.5mm, and the diameter of the undercut is 83mm. TiB 2 - The height of the Cu composite target is 35mm, and the maximum diameter φ is 100mm. This ensures that TiB 2 -Cu composite target and the installation position of the target in the coating equipment are well matched. Cu metal par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com