Antistatic and wear-resistant rubber material for rubber covered roller

A rubber material and wear-resistant technology, which is used in the field of rubber materials for anti-static and wear-resistant rubber rollers, can solve the problems of poor mechanical properties, anti-static and wear resistance, wear or cracks, and poor rebound. Achieve the effect of shortening vulcanization time, improving surface properties and increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

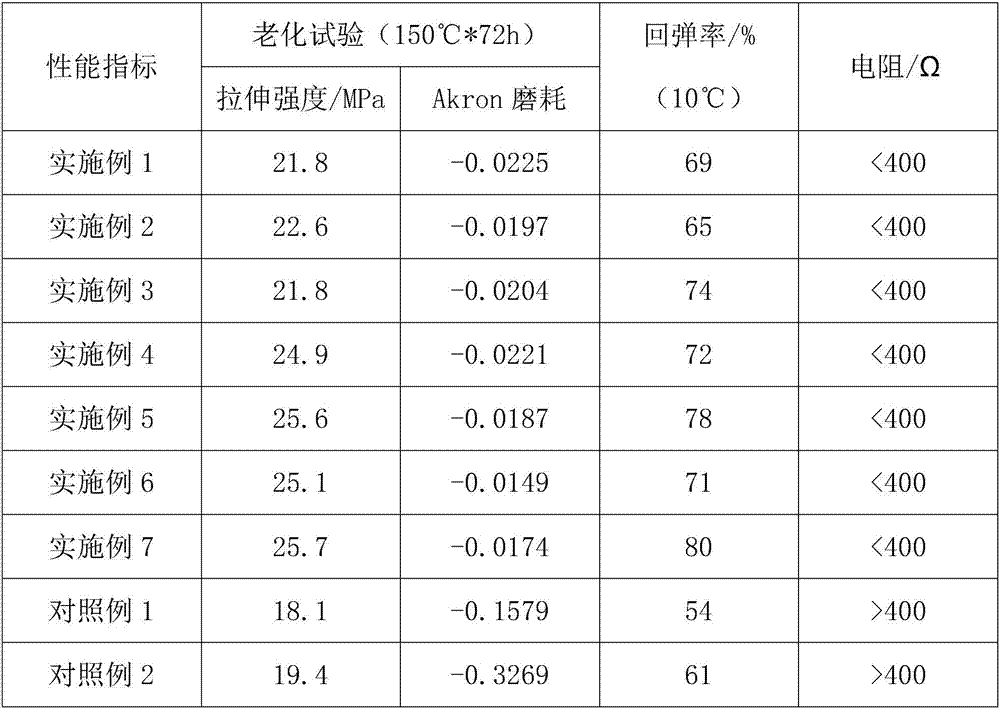

Examples

Embodiment 1

[0026] A kind of wear-resistant antistatic rubber roller rubber material, its raw material comprises by weight:

[0027] 50 parts of carboxylated nitrile rubber, 50 parts of EPDM rubber, 25 parts of naphthenic oil, 15 parts of reinforcing agent, 6 parts of modified nano-zinc oxide, 6 parts of plasticizer, 3 parts of vulcanizing agent, and 1 part of accelerator , 5 parts of additives;

[0028] Wherein, in the EPDM rubber, the weight percent content of the propylene unit is 40%, the weight percent content of the ethylene unit is 54%, and the weight percent content of the ethylidene norbornene unit is 6%.

Embodiment 2

[0030] A kind of wear-resistant antistatic rubber roller rubber material, its raw material comprises by weight:

[0031] 70 parts of carboxylated nitrile rubber, 30 parts of EPDM rubber, 5 parts of naphthenic oil, 30 parts of reinforcing agent, 3 parts of modified nano zinc oxide, 10 parts of plasticizer, 2 parts of vulcanizing agent, 3 parts of accelerator , 1 part of auxiliary agent;

[0032] Wherein, in the EPDM rubber, the weight percentage of the propylene unit is 50%, the weight percentage of the ethylene unit is 46%, and the weight percentage of the ethylidene norbornene unit is 4%.

Embodiment 3

[0034] A kind of wear-resistant antistatic rubber roller rubber material, its raw material comprises by weight:

[0035] 60 parts of carboxylated nitrile rubber, 40 parts of EPDM rubber, 13 parts of naphthenic oil, 20 parts of reinforcing agent, 5 parts of modified nano zinc oxide, 8 parts of plasticizer, 2.5 parts of vulcanizing agent, 2 parts of accelerator , 4 parts of additives;

[0036] Wherein, the weight percentage of propylene unit in EPDM rubber is 50%, the weight percentage of ethylene unit is 45%, and the weight percentage of ethylidene norbornene unit is 5%; EPDM rubber The Mooney viscosity (ML100℃1+4) is 75;

[0037] The preparation process of the modified nano-zinc oxide includes: adding sucrose ester to 0.5mol / L zinc nitrate solution to obtain a mixed solution, the amount of sucrose ester added is 0.25g / L; adding the obtained mixed solution dropwise to a concentration of 1.0 In mol / L sodium hydroxide solution, pretreatment for 1.5h, ultrasonic reaction for 10m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com