Functional mesoporous silicon dioxide nanoparticles with effect of resisting ageing and preparing method and application of functional mesoporous silicon dioxide nanoparticles

A technology of mesoporous silica and nanoparticles, which is applied in the field of functional mesoporous silica nanoparticles and their preparation, can solve the problem of non-reported in the field of multifunctional polymer additives, reduction of physical and mechanical properties, and anti-aging effects. Reduce and other problems, achieve good application prospects, reduce migration, and improve physical and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

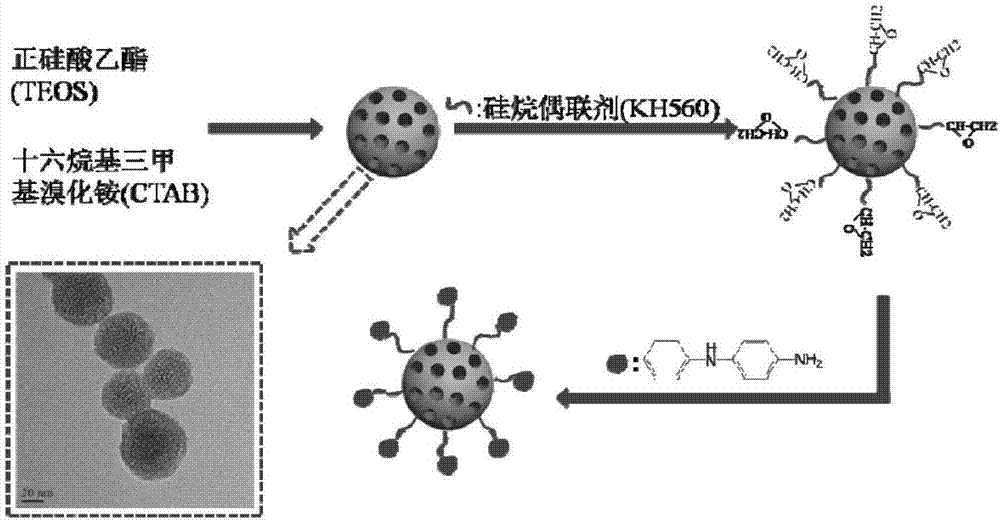

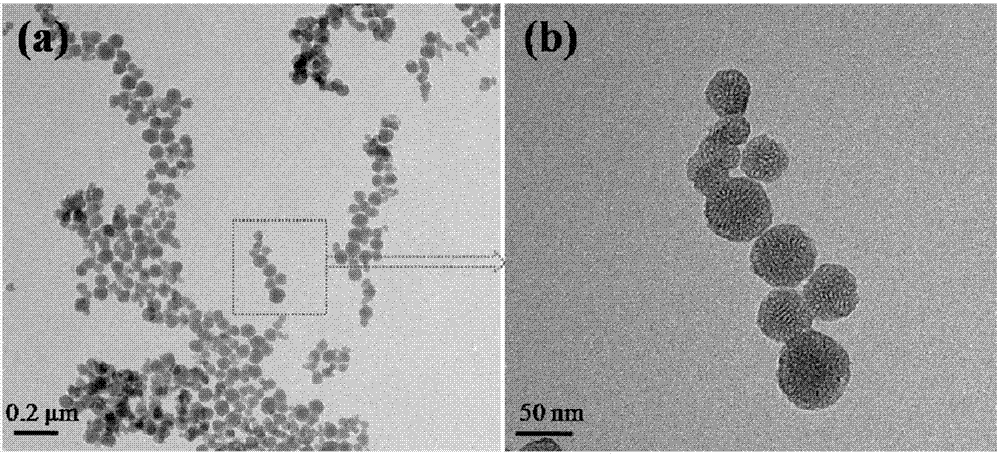

[0033] Dissolve 0.35g of surfactant (CTAB) and 3.0g of ammonia water (concentration: 25wt%) in 140ml of deionized water, stir at 80°C for 0.5h, then add 3.0g of tetraethyl orthosilicate (TEOS) dropwise to The resulting solution was stirred for 2 hours, centrifuged and dried, and placed in a muffle furnace at 700° C. for 3 hours to remove residual surfactant (CTAB) to obtain mesoporous silica nanoparticles (MS). figure 2 It is a transmission electron microscope picture of the obtained mesoporous silica nanoparticles. It can be seen from the figure that mesoporous silica nanoparticles have a unique nano-mesoporous structure, a large specific surface area, and a particle size of about 20-50nm.

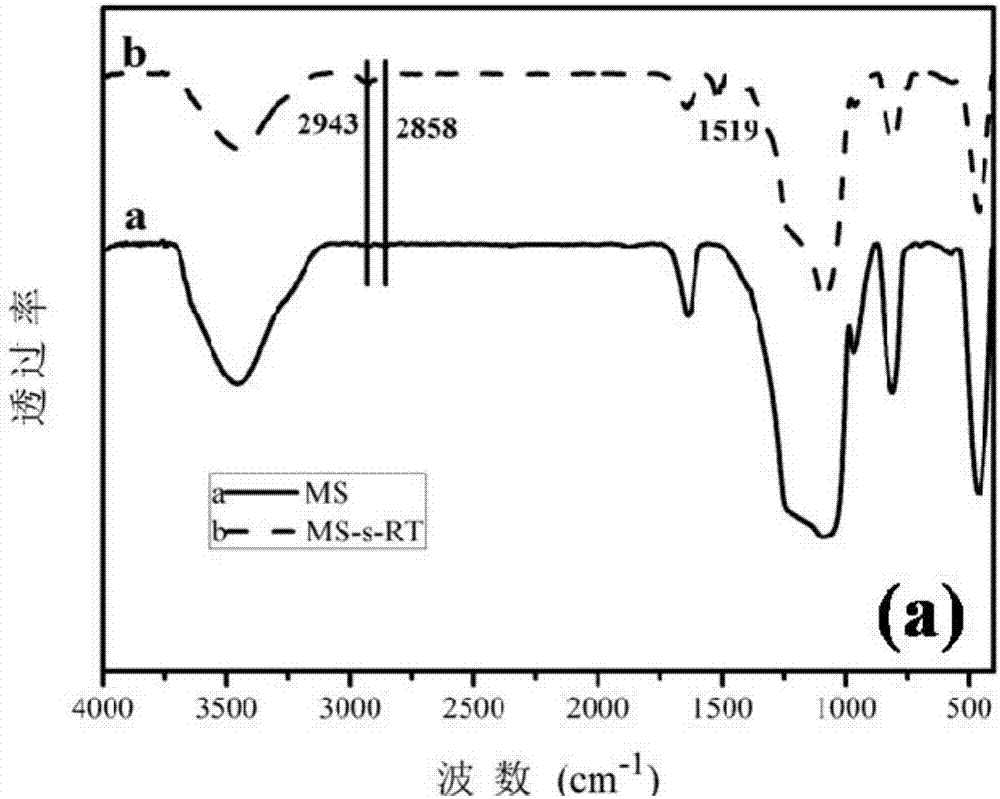

[0034] Add 8 g of prepared mesoporous silica nanoparticles (MS) and 2.4 g of silane coupling agent (KH560) into a three-necked flask filled with absolute ethanol (150 ml), and react at 90 ° C for 12 h to obtain the modified mesoporous Porous silica intermediate product (m-MS); then reac...

Embodiment 2

[0041] Dissolve 0.4g of surfactant (CTAC) and 3.0g of ammonia water (concentration: 25wt%) in 150ml of deionized water, stir at 60°C for 2h, then add 3.0g of tetraethyl orthosilicate dropwise to the resulting solution , stirred and reacted for 5 h, and after centrifugal drying, placed in a muffle furnace at 800° C. for 2 h to remove residual surfactant (CTAC) to obtain the desired mesoporous silica nanoparticles. Take 15g of prepared mesoporous silica particles in 150ml of absolute ethanol, then add 0.75g of γ-(2,3-glycidoxy)propyltrimethoxysilane, and react at 120°C for 10h to obtain an intermediate product (m-MS), then 1.2g of p-aminodiphenylamine and the intermediate product of the previous step were stirred and reacted for 8h at 100°C to obtain functional mesoporous silica nanoparticles (MS-s-RT) with anti-aging effect ). 30 g of the prepared functional mesoporous silica nanoparticles were added to 100 g of styrene-butadiene rubber to prepare a styrene-butadiene rubber co...

Embodiment 3

[0045] Dissolve 0.3g of surfactant (CTAB) and 4.0g of ammonia water (concentration: 25wt%) in 150ml of deionized water, stir at 50°C for 1h, then add 2.0g of tetraethyl orthosilicate dropwise to the resulting solution , stirred and reacted for 1 h, and after centrifugal drying, placed in a muffle furnace at 500° C. for 5 h to remove residual surfactant (CTAB) to obtain the desired mesoporous silica nanoparticles. Take 15g of mesoporous silica nanoparticles, then add 1.5g of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, and react at 80°C for 24h to obtain an intermediate product (m-MS). To the mixture, 4.5 g of p-aminodiphenylamine was further added, and the mixture was stirred and reacted at 60° C. for 12 hours to obtain the desired functional mesoporous silica nanoparticles (MS-s-RT). After adding 30phr functional mesoporous silica nanoparticles to 100phr styrene-butadiene rubber, compared with SBR / m-MS / RT composites, the oxidation induction period of SBR / MS-s-RT composites was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com