Integral hydrophobic calcium silicate thermal insulation spray coating and its manufacturing method

A technology of heat-insulating spray coating and manufacturing method, applied in the field of coating, to achieve the effect of long fire resistance limit, reduced manufacturing cost, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

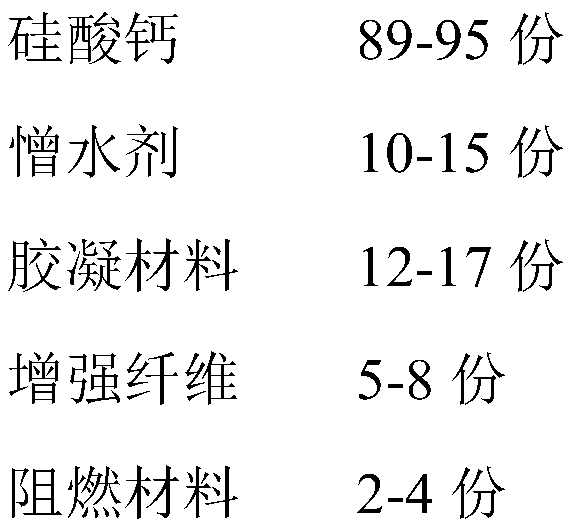

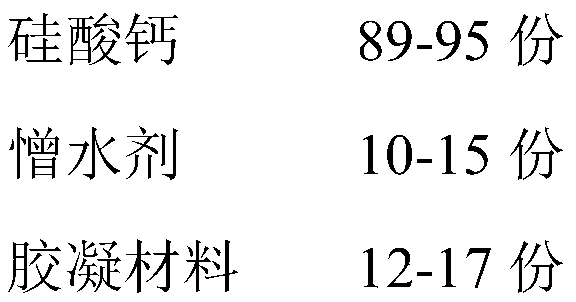

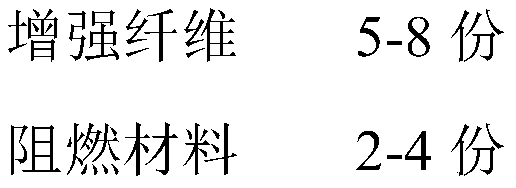

Method used

Image

Examples

Embodiment 1

[0054] Prepare calcium silicate according to the above steps (1)-(3), weigh 100g of calcium silicate and 8g of silane coupling agent, put the calcium silicate and silane coupling agent into a high-temperature furnace, and raise the temperature to 155°C for modification; After modification, calcium silicate is granulated to obtain calcium silicate particles, which are added to the infiltration treatment furnace, and 11g of organic silicon compound is pre-added in the infiltration treatment furnace; before infiltration, the internal pressure is controlled to be 0.2Pa. Then raise the temperature of the infiltration treatment furnace to 180°C, and infiltrate treatment for 12 hours; after natural cooling, hydrophobic calcium silicate particles are obtained, and calcium silicate particles are mixed with 13g of gel material, 6g of reinforcing fiber and 2.1g of flame retardant material to obtain silicic acid Calcium coating.

[0055] Take 10g of the prepared calcium silicate coating ...

Embodiment 2

[0060] Prepare calcium silicate according to the above steps (1)-(3), weigh 100g of calcium silicate and 9g of aluminate coupling agent, put calcium silicate and aluminate coupling agent into a high-temperature furnace, and heat up to 160°C Modification; after modification, calcium silicate is granulated to obtain calcium silicate particles, and the calcium silicate particles are added to the infiltration treatment furnace, and 11g of organic silicon compound is pre-added in the infiltration treatment furnace; before infiltration, the vacuum is controlled to The internal pressure is 0.3 Pa. Then raise the temperature of the infiltration treatment furnace to 185°C, and infiltrate treatment for 12 hours; after natural cooling, hydrophobic calcium silicate particles are obtained, and calcium silicate particles are mixed with 14g of gel material, 6g of reinforcing fiber and 2.5g of flame retardant material to obtain silicic acid Calcium coating.

[0061] Take 10g of the prepared ...

Embodiment 3

[0065] Prepare calcium silicate according to the above steps (1)-(3), weigh the mixture of 100g calcium silicate, 9g titanate coupling agent and sodium stearate, put calcium silicate and the mixture into high temperature furnace, heat up Modified at 160°C; after modification, calcium silicate was granulated to obtain calcium silicate particles, which were added to the permeation treatment furnace, and 14g of organosilicon compound was pre-added in the permeation treatment furnace; before permeation, pumping True control to the internal pressure of 0.3Pa. Then raise the temperature of the infiltration treatment furnace to 190°C, and infiltrate treatment for 12 hours; after natural cooling, hydrophobic calcium silicate particles are obtained, and calcium silicate particles are mixed with 15g of gel material, 7g of reinforcing fiber and 2.8g of flame retardant material to obtain silicic acid Calcium coating.

[0066] Take 10g of the prepared calcium silicate coating as test samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com