Preparation method for emulsified bitumen cold-recycled mixture based on internal friction angle

A technology of cold recycled mixture and emulsified asphalt, which is applied in the direction of applying stable tension/pressure to test material strength, analyze materials, and material inspection products. It can solve permanent deformation and cannot fully guarantee the service performance of emulsified asphalt mixture. Fully consider the shear resistance of emulsified asphalt mixture and other issues to achieve the effect of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

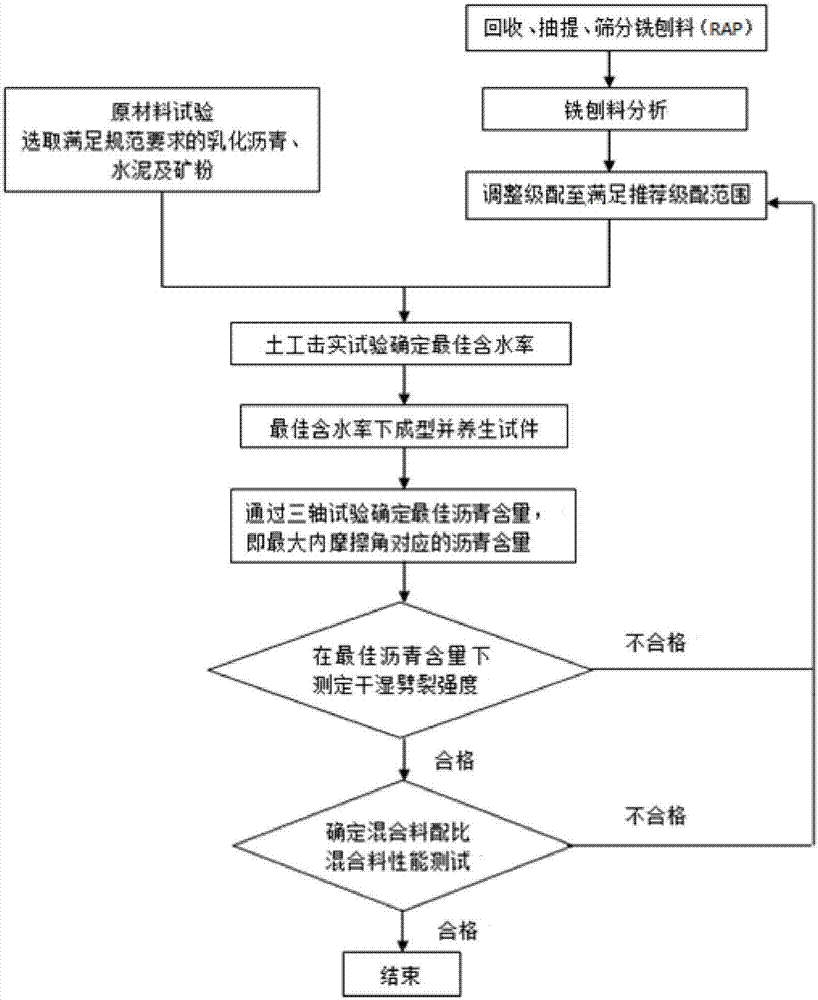

[0024] A method for preparing emulsified asphalt cold recycled mixture based on internal friction angle, comprising the steps of:

[0025] (a) After recovering and analyzing the milling material, adjust the grading to meet the specified grading range

[0026] Firstly, the original asphalt pavement milling material is obtained, which mainly includes waste asphalt, coarse sand and fine sand, and the material is dried to constant weight to remove the moisture in the recycled material. Then carry out gradation analysis on the recovered materials through extraction and sieving experiments, compare the analysis results with the design gradation range of emulsified asphalt cold recycled mixture in 5.4.2 of the "Technical Specifications for Highway ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com