Online processing structure for main spindle bearing position of fan

A spindle bearing and bearing position technology, applied in metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve problems such as uncontrollable planned maintenance of equipment, reduce disassembly, improve processing efficiency, and ensure cylindricity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

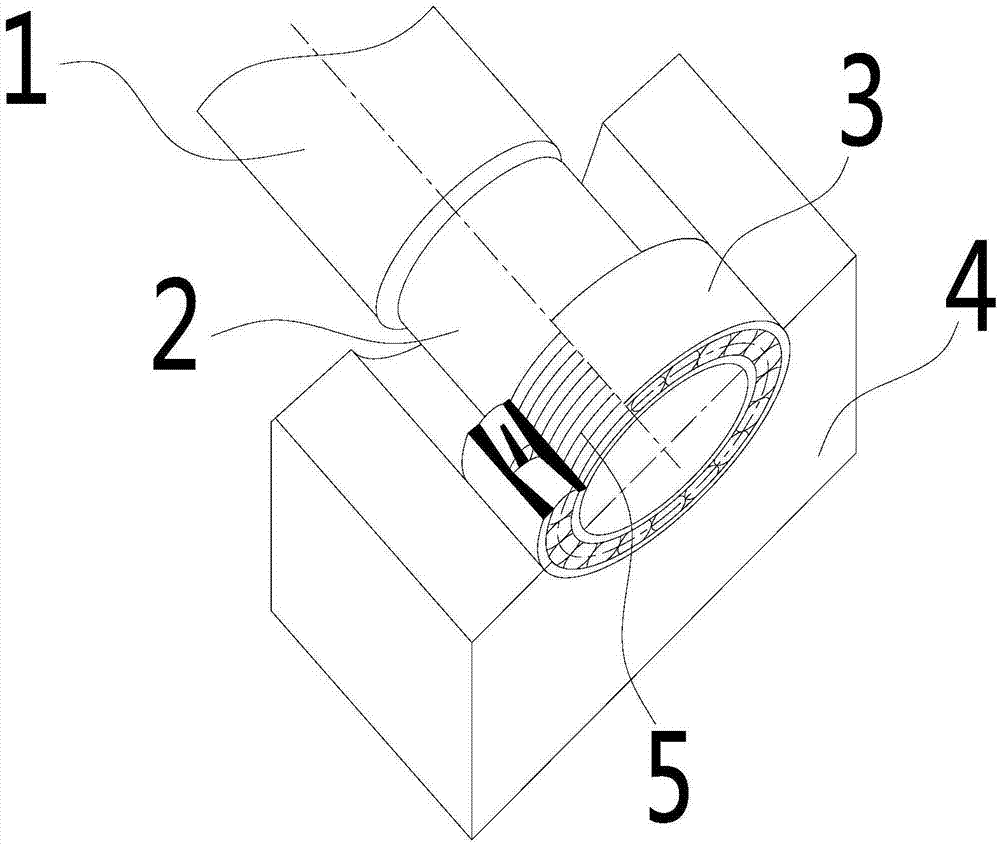

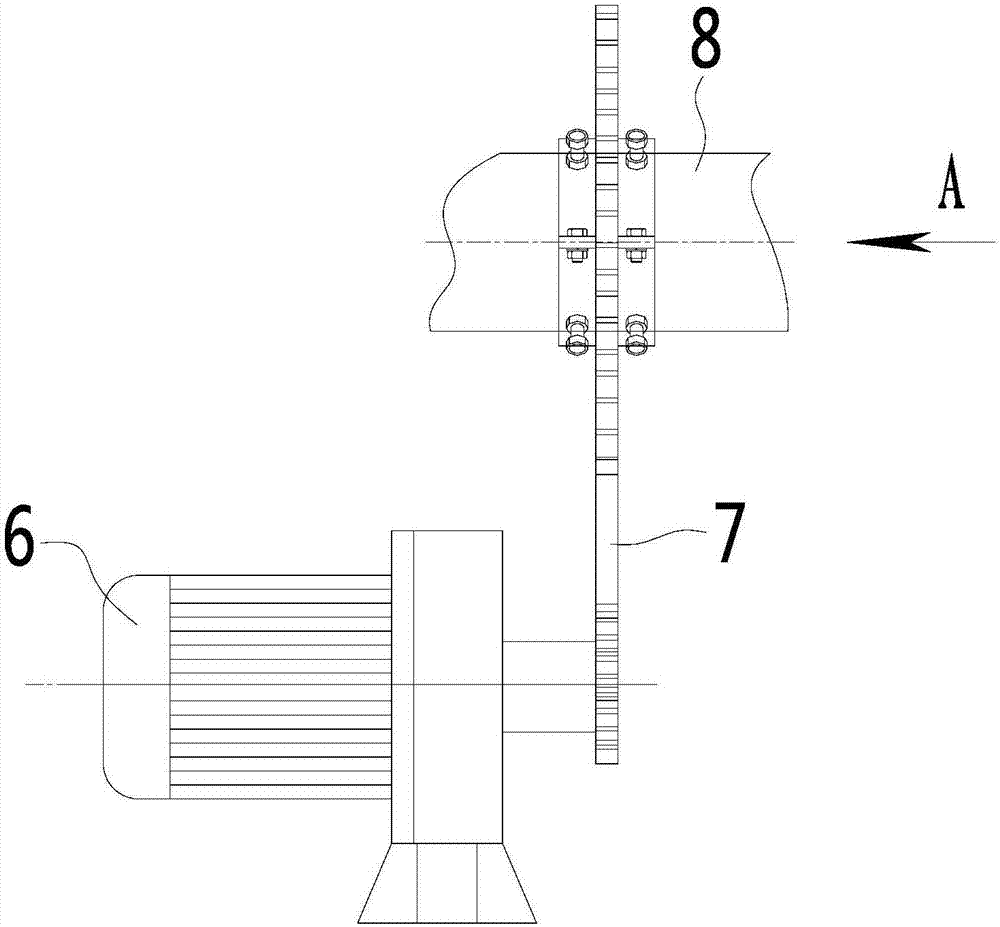

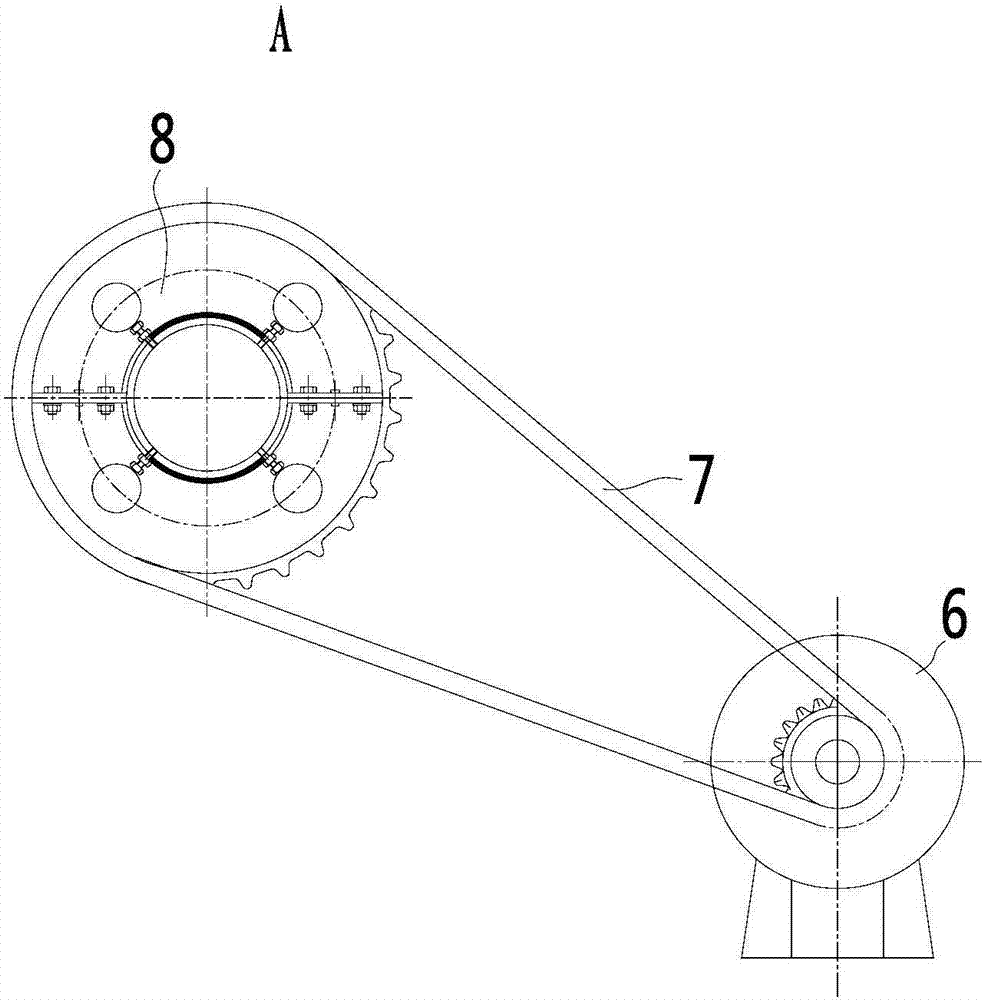

[0024] Such as Figure 1 to Figure 6 The shown online processing structure of the fan main shaft bearing position includes the fan main shaft 1 and the lower bearing housing 4 for supporting the fan main shaft 1, including the grinding processing device 13 and the fan main shaft driving device, and the bearing position 2 at the end of the fan main shaft 1 and Temporary support bearings 3 are arranged between the lower bearing seats 4 , wherein the fan main shaft driving device drives the fan main shaft 1 to rotate, and the grinding processing device 13 processes the bearing position 2 rotating around the central axis of the fan main shaft 1 .

[0025] Through the ingenious structural design of the present invention, the grinding processing device 13 can grind the cemented bearing inner ring in the narrow bearing position 2 without disassembly, so as to ensure the beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com