Full mold casting mold

A technology of full mold casting and mould, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., and can solve problems such as the influence of full mold castings and the quality of castings, so as to ensure the quality of castings, prevent shrinkage cavities, and improve the qualified rate of products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

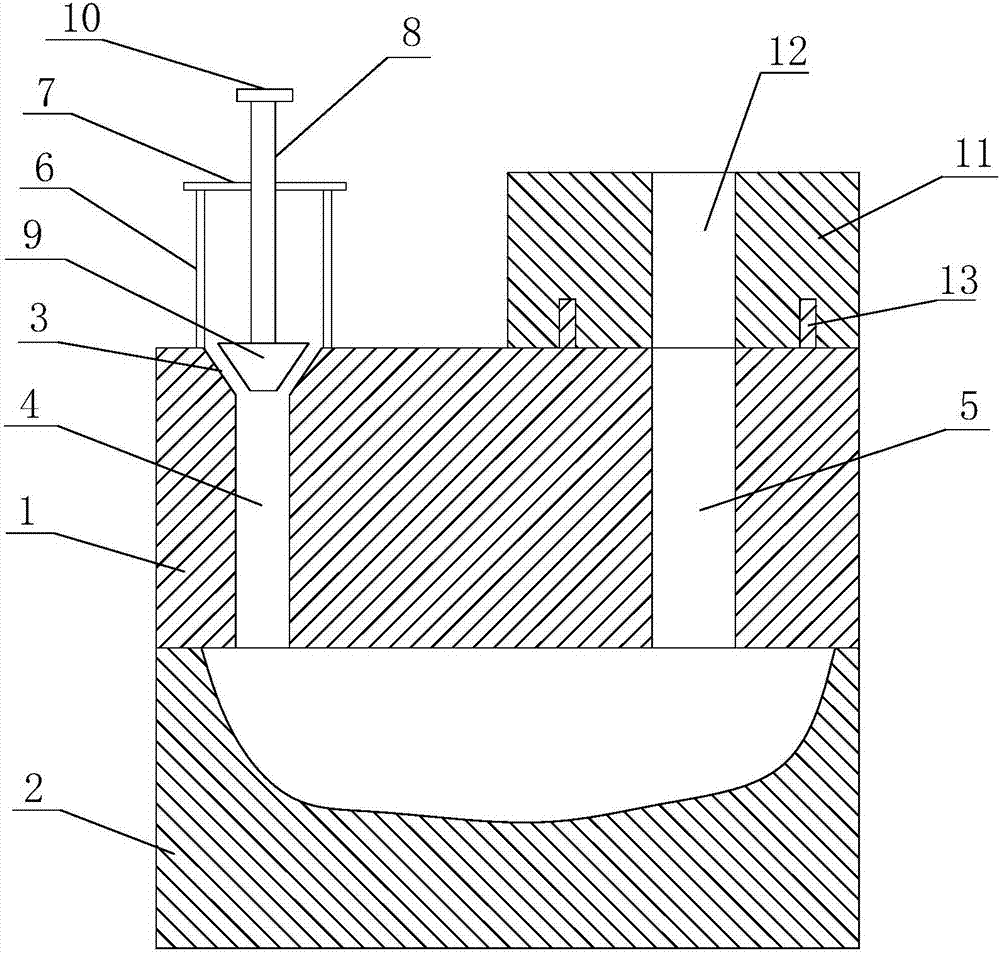

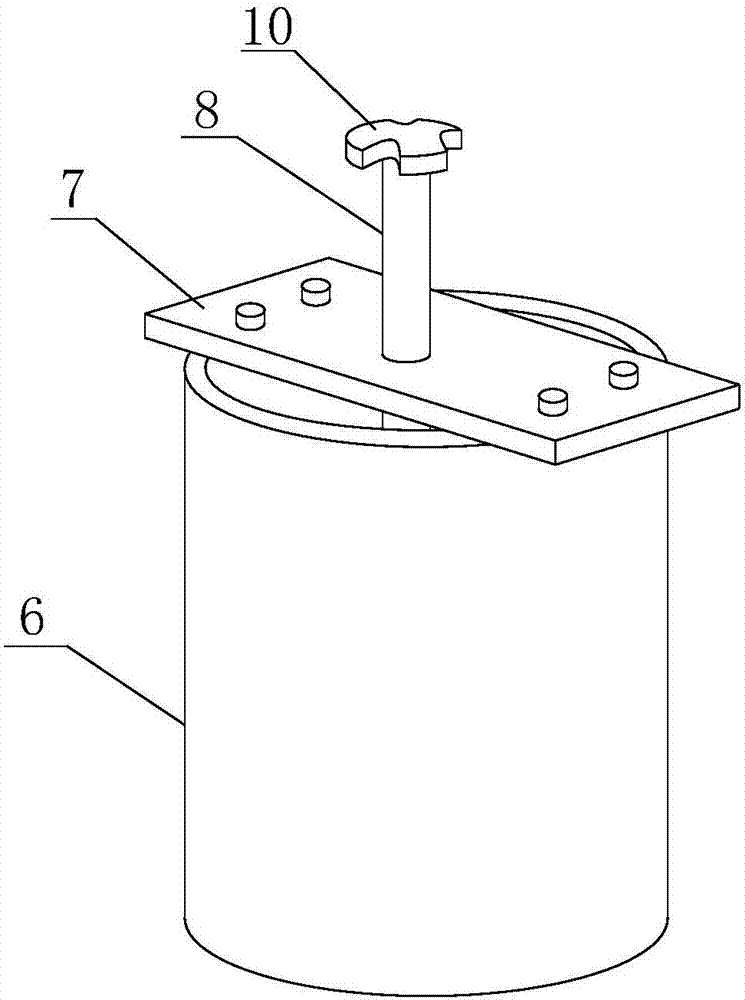

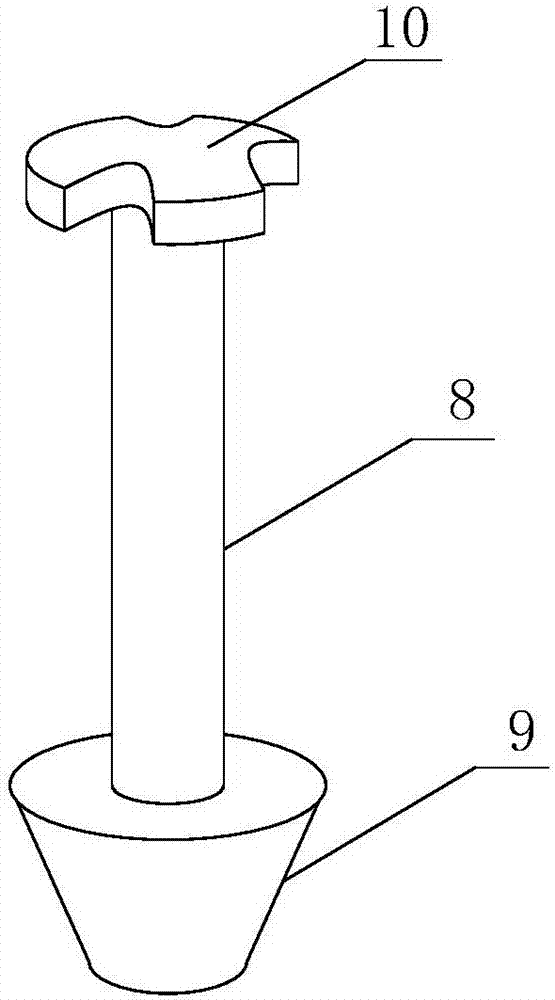

[0015] like Figure 1 to Figure 3 As shown, a kind of solid casting mold provided by the present invention includes an upper mold 1 and a lower mold 2. When casting, the foam model is filled in the lower mold 2, and is tamped and buried with glass sand, and the upper mold 1 is closed and cast forming. The upper mold 1 is provided with a sprue cup 3, a casting channel 4 and a riser 5, the sprue cup 3 is funnel-shaped, and the lower end of the sprue cup 3 is connected with the casting channel 4, and the casting channel 4 can be a sprue , can also be other forms of channels, here we take the sprue as an example for specific description. A connecting pipe 6 is arranged above the sprue cup 3, and the connecting pipe 6 is fixedly connected with the upper mold 1. A horizontal plate 7 is erected above the connecting pipe 6, and the horizontal plate 7 is co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap