Side piercing tapered wedge mechanism with material pressing function

A side punching and functional technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of complex production process, no pressing function, increased mold cost, etc., to ensure accuracy and quality, and save development. cost and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

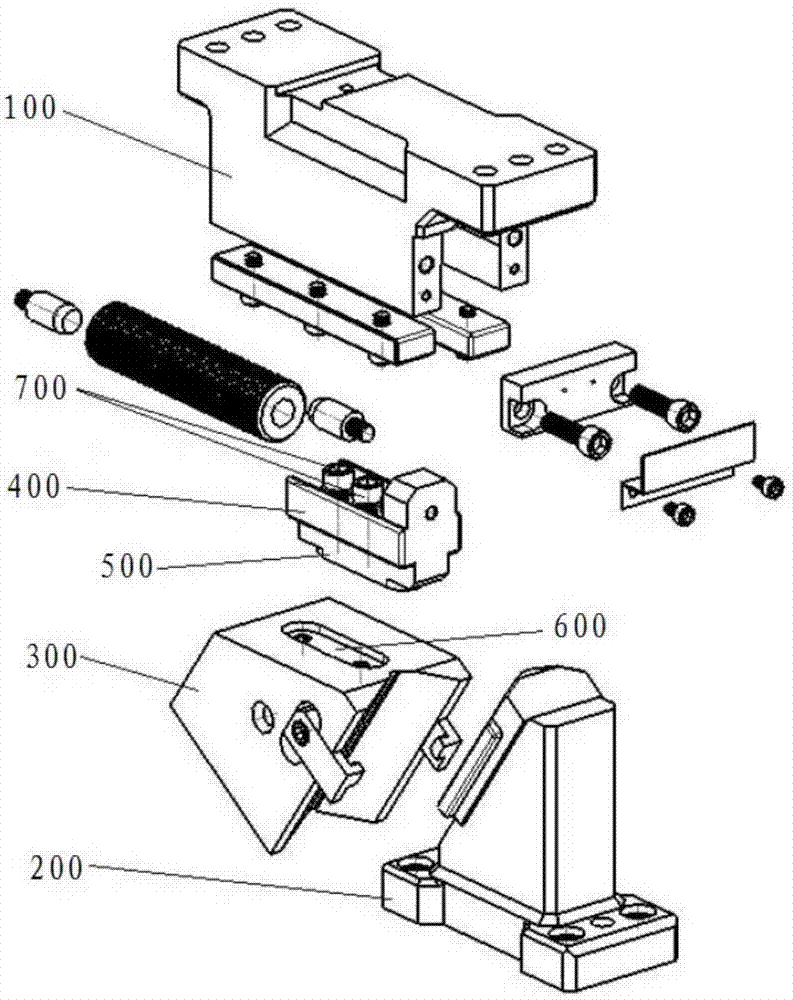

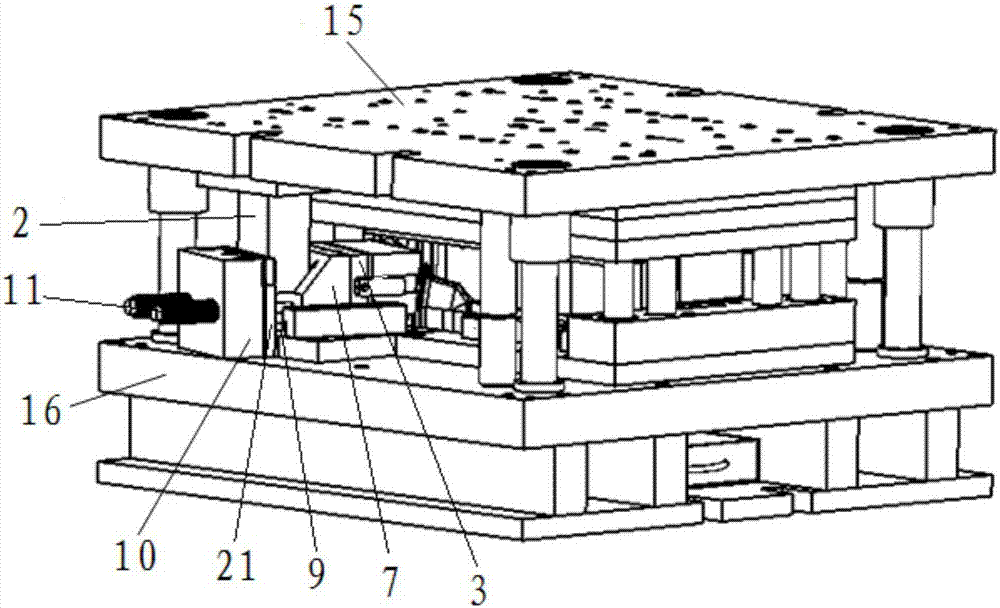

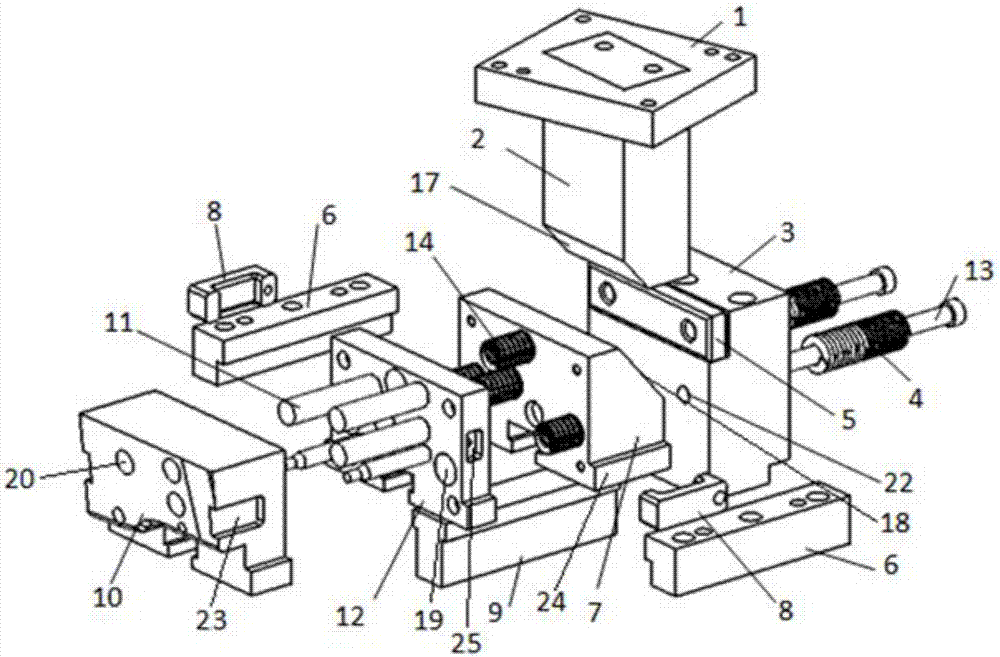

[0026] Embodiments of the present invention: as figure 2 , image 3 and Figure 4 As shown, a side punching wedge mechanism with a pressing function includes an upper slider 2, a side guide 3, a lower slider 7, a bottom guide 9 and a punch assembly 21, and the upper slider 2 is fixed by the upper The plate 1 is fixedly installed on the bottom of the upper template 15, the setting of the fixed plate 1 facilitates the disassembly and assembly of the upper slider 2, and the side guide blocks 3 and the bottom guide blocks 9 are fixedly installed on the top of the lower template 16. In order to increase the upper slider 2 and The sliding smoothness between the side guide blocks 3, wherein the side guide block 3 is provided with a guide plate 5; the lower block 7 and the punch assembly 21 are sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com