Preparation method of platinum/molybdenum disulfide nanosheet/graphene three-dimensional composite electrode catalyst

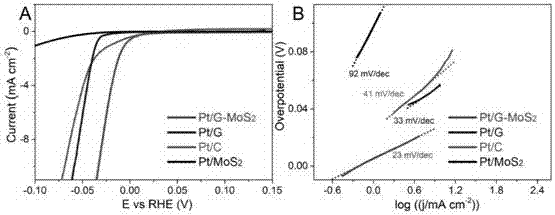

An electrode catalyst, molybdenum disulfide technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, electrodes, etc., to achieve the effects of good stability, high catalytic activity, good application prospects and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

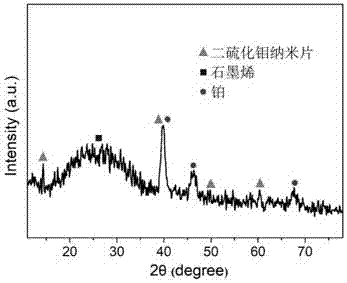

[0027] Such as figure 1 Shown, the present invention provides a kind of preparation method of platinum / molybdenum disulfide nanosheet / graphene three-dimensional composite electrode catalyst, comprises the following steps:

[0028] Step 1: ultrasonically disperse the molybdenum disulfide nanosheets in a mixed solution of ethylene glycol and isopropanol to obtain a dispersion of molybdenum disulfide nanosheets; the ultrasonic time is 0.5-6 hours, the ultrasonic temperature is 0°C-60°C, and the The concentration of molybdenum nanosheet dispersion is 0.1g / L-5g / L.

[0029] Step 2, adding graphite oxide to the molybdenum disulfide nanosheet dispersion in step 1 and performing ultrasonic treatment to obtain a molybdenum disulfide nanosheet / graphene oxide binary composite solution; the mass ratio of graphite oxide added to molybdenum disulfide 1:20–20:1, ultrasonic time 0.5–6 hours, ultrasonic temperature 0°C–60°C.

[0030] Step 3, adding potassium chloroplatinite solution to the mo...

Embodiment 1

[0035] Step 1: ultrasonically disperse the molybdenum disulfide nanosheets in a mixed solution of ethylene glycol and isopropanol to obtain a molybdenum disulfide nanosheet dispersion; the ultrasonic time is 0.5 hours, the ultrasonic temperature is 0°C, and the molybdenum disulfide nanosheet dispersion is The concentration is 0.1g / L.

[0036] Step 2, adding graphite oxide to the molybdenum disulfide nanosheet dispersion in step 1 and performing ultrasonic treatment to obtain a molybdenum disulfide nanosheet / graphene oxide binary composite solution; the mass ratio of graphite oxide added to molybdenum disulfide The ratio is 1:20, the ultrasonic time is 0.5 hour, and the ultrasonic temperature is 0°C.

[0037] Step 3, adding potassium chloroplatinite solution to the molybdenum disulfide nanosheet / graphene oxide binary composite solution in step 2, and using magnetic stirring to mix the system evenly to obtain potassium chloroplatinite / molybdenum disulfide nanosheet / graphene ox...

Embodiment 2

[0042] Step 1: ultrasonically disperse the molybdenum disulfide nanosheets in a mixed solution of ethylene glycol and isopropanol to obtain a molybdenum disulfide nanosheet dispersion; the ultrasonic time is 1 hour, the ultrasonic temperature is 20°C, and the molybdenum disulfide nanosheet dispersion is The concentration is 1.67g / L.

[0043] Step 2, adding graphite oxide to the molybdenum disulfide nanosheet dispersion in step 1 and performing ultrasonic treatment to obtain a molybdenum disulfide nanosheet / graphene oxide binary composite solution; the mass ratio of graphite oxide added to molybdenum disulfide The ratio is 1:1, the ultrasonic time is 1 hour, and the ultrasonic temperature is 20°C.

[0044] Step 3, adding potassium chloroplatinite solution to the molybdenum disulfide nanosheet / graphene oxide binary composite solution in step 2, and using magnetic stirring to mix the system evenly to obtain potassium chloroplatinite / molybdenum disulfide nanosheet / graphene oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com