Leather shoe upper making process

A production process and technology of upper surface, applied in shoe uppers, footwear, boot legs, etc., can solve the problems of skin and mucous membrane irritation, unfavorable environmental protection and health, easy to deform, etc., to increase the firmness of the cortex and the green material Environmental protection, the effect of ensuring the quality of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

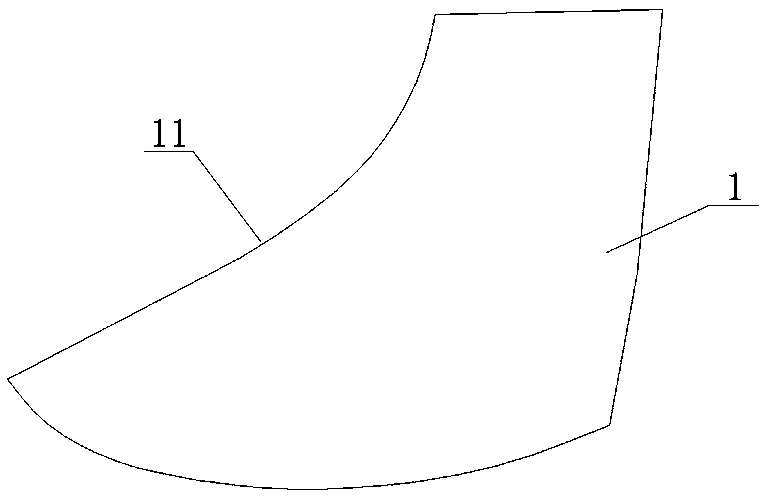

[0012] The leather shoe upper manufacturing process of the present invention is characterized in that it comprises the following steps, ① intercepting a flat leather surface according to the size of the shoe front upper surface, and applying hot-melt sizing glue to the back of the leather surface according to the shaping warp and latitude lines, and the operation process is as follows: High-temperature gluing machine, the temperature of the glue tank is 200°C, the temperature of the roller is 200°C, and the width of the roller is 3-4cm. The hot melt adhesive is applied to the shaping warp and weft line on the back of the leather through the rolling of the roller. In the stilt shaping step, the leather surface is supported and shaped, and it is not easy to cool and shrink to return to the original leather surface shape; ②Paste the shaping lining cloth, paste the shaping cloth on the back of the leather face, the overall edge of the shaping cloth is indented 3-7mm from the edge of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com