Interval Optimization Method for Structural Dimensional Parameters and Dimensional Tolerance of Mechanical Parts

A technology of mechanical parts and structural dimensions, applied in the field of mechanical structure optimization design, can solve problems that affect the performance of structural design optimization targets or change constraints, structural dimension parameters and dimensional tolerances cannot be optimized simultaneously

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

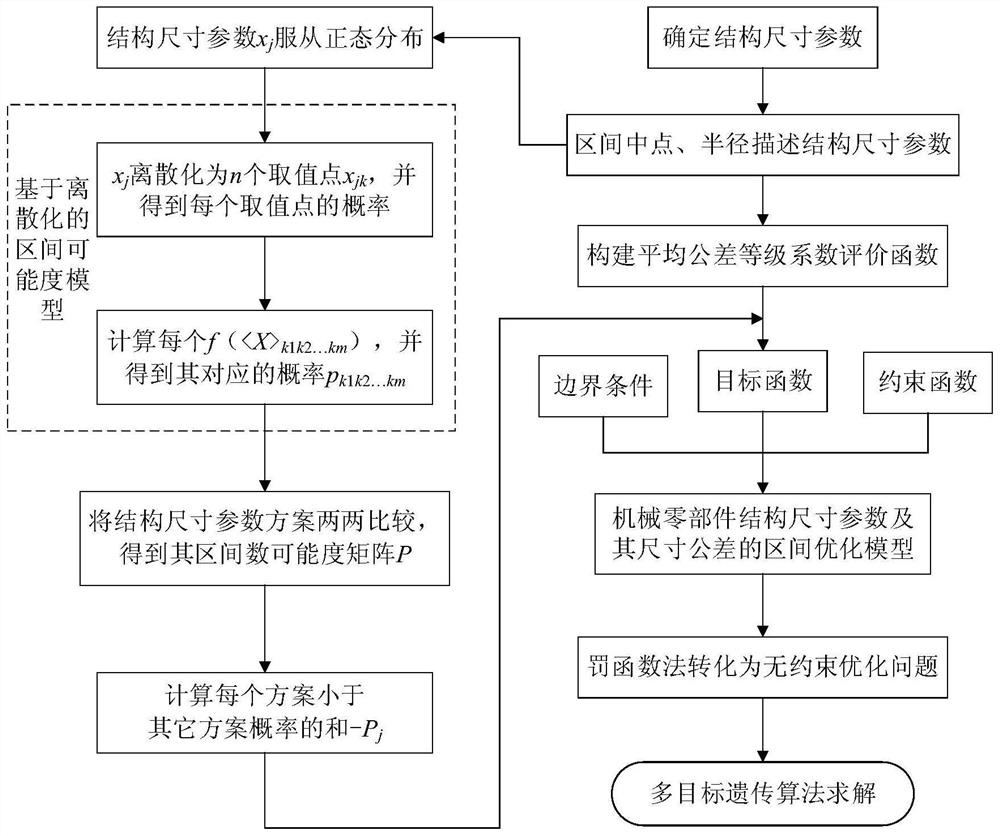

Method used

Image

Examples

Embodiment 1

[0082] Consider the following deterministic optimization problem with two design parameters:

[0083]

[0084] According to formula (5), n is set to 10, and the obtained m-dimensional possibility matrix 10×10 for:

[0085]

[0086] According to formula (13), the above optimization problem is transformed into:

[0087]

[0088] The optimal design parameters in the above formula are

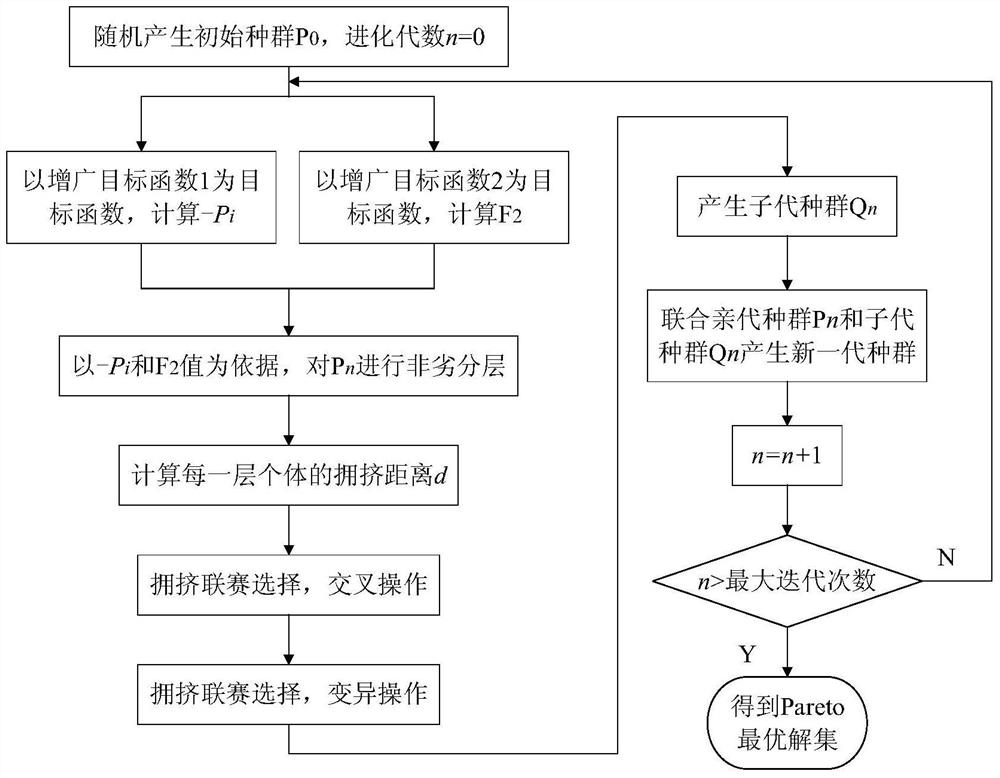

[0089] Transform it into an unconstrained optimization problem using formula (16), combining figure 2 , using NSGA-Ⅱ genetic algorithm programming calculation, the population size is 100, iteration 400 generations, the crossover probability of arithmetic crossover is 0.8, and the mutation probability of Gaussian mutation is 0.1.

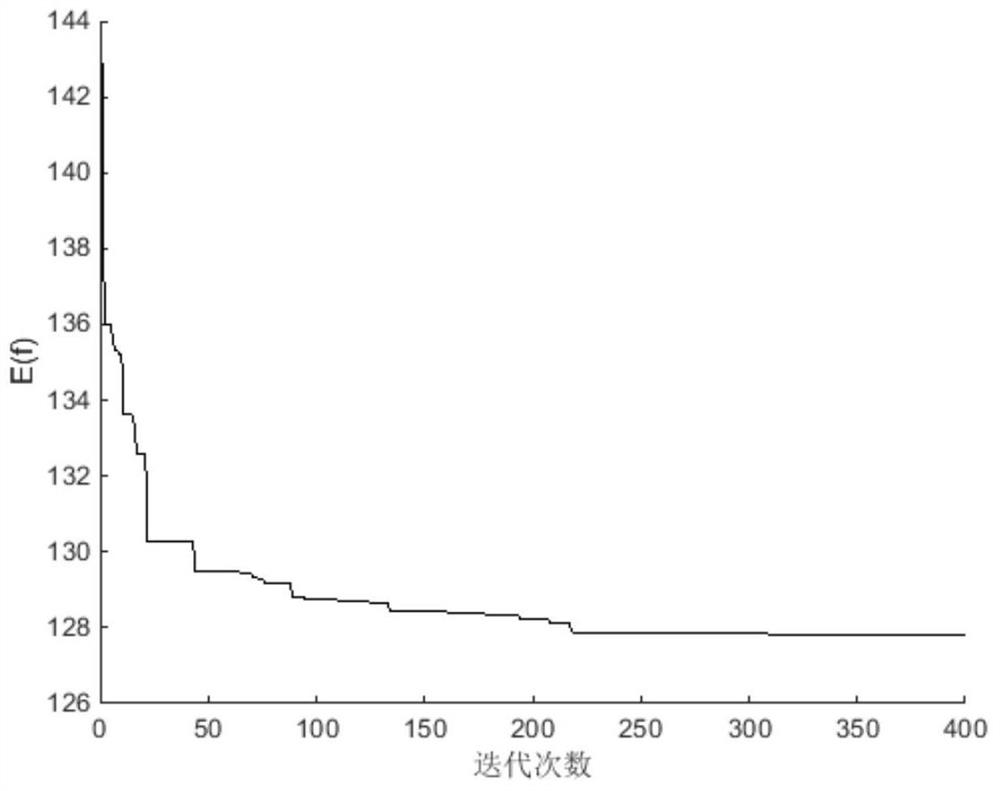

[0090] combine image 3 , Figure 4 It is known that there are many obvious jumps before the iteration 220 of the genetic algorithm, indicating that a better individual has been found. After 220 generations, the target performa...

Embodiment 2

[0096] Aiming at the problem of the large radial size and insufficient compact structure of the retreating machine of a large-caliber artillery, this paper adopts the above optimization model to obtain its parameter error scheme. The main structural parameters of the brake are the working length L of the brake and the working area of the piston A 0 , The inner diameter of the withdrawal cylinder D T , Outer diameter of brake rod d T , Diameter of the inner cavity of the brake rod d 1 , control ring diameter d p , Outer diameter of the withdrawal cylinder D 1 , where other parameters depend on the inner diameter of the brake cylinder D T and the outer diameter of the brake rod d T get, select D T and d T is the key design parameter [x 1 , x 2 ]=[D T , d T ]; the objective function is to minimize the absolute value of the difference between the working area of the piston obtained by considering the actual structure and the working area of the pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com