Vehicle headlamp assembly simulation loading detection device

A technology of automobile headlights and detection devices, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of uneven assembly gaps and uneven surface heights, and reduce manpower, reduce failure rates, The effect of improving molding productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the specific technical details will be further elaborated below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto.

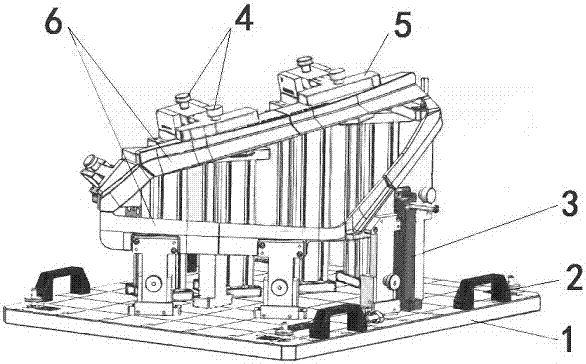

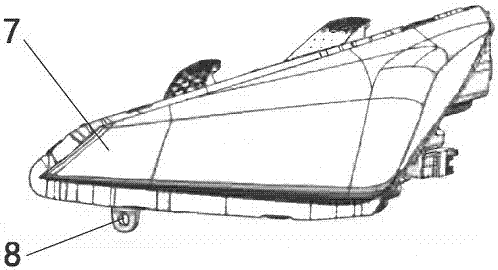

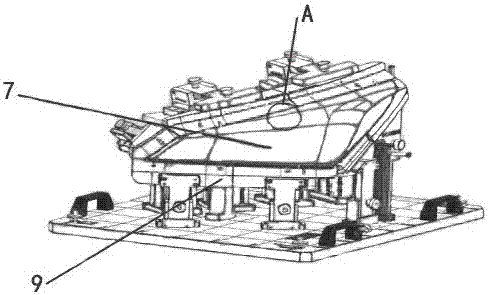

[0022] Such as figure 1 , figure 2 , image 3 As shown in the present invention, a vehicle headlight lamp assembly simulation loading detection device described in the present invention is characterized in that it includes a horizontal support base plate 1, a support guide column 3, a compression pin 4, a compression module 5, and a simulation block 6 and the headlight lamp assembly 7, the position, shape, size and quantity of the simulation block 6 are determined according to the requirements of the digital simulation of the vehicle model, and the space size for loading the headlight lamp assembly 7 is determined, and the design is based on the loading size The benchm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com