Evaporator suitable for steam waste heat type ORC power generation system

A power generation system, steam waste heat technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc. The effect of high flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

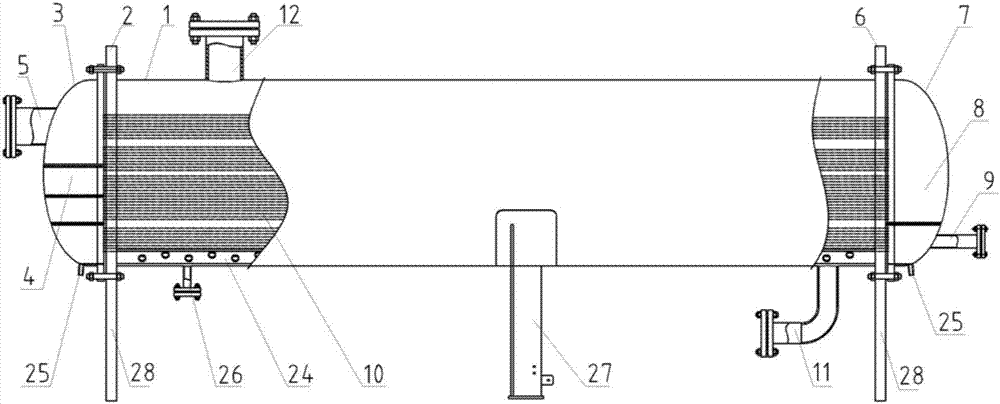

[0028] see figure 1 , the present invention provides an evaporator suitable for a steam waste heat type ORC power generation system, and the structure of its preferred embodiment includes a cylindrical shell 1 .

[0029] A first tube sheet 2 is arranged radially on one end surface of the shell 1, and a first head 3 is installed on the outside of the first tube sheet 2, and a first tube box 4 is formed between the first tube sheet 2 and the first head 3 , the first head 3 is provided with a steam inlet 5 near the top of the first pipe box 4 .

[0030] On the other end surface of the shell 1, a second tube plate 6 is arranged radially, and a second head 7 is installed on the outside of the second tube plate 6, and a second tube box is formed between the second tube plate 6 and the second head 7 8. The second head 7 is provided with a condensation water outlet 9 near the bottom of the second pipe box 8 .

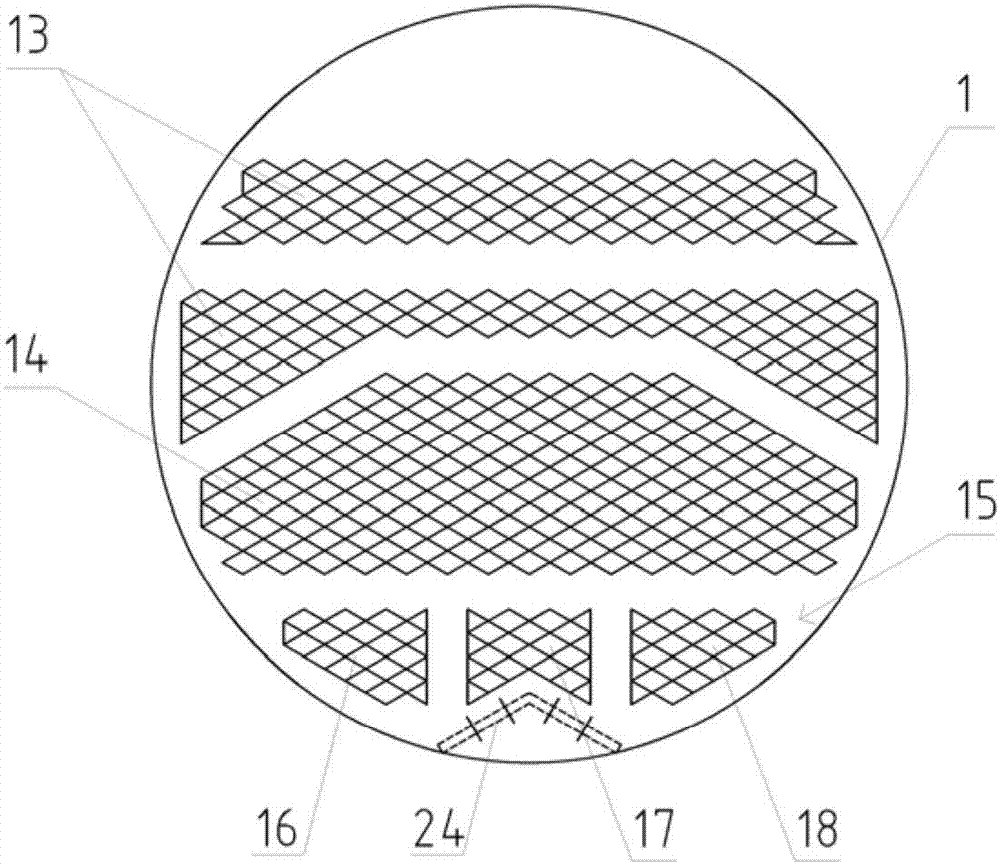

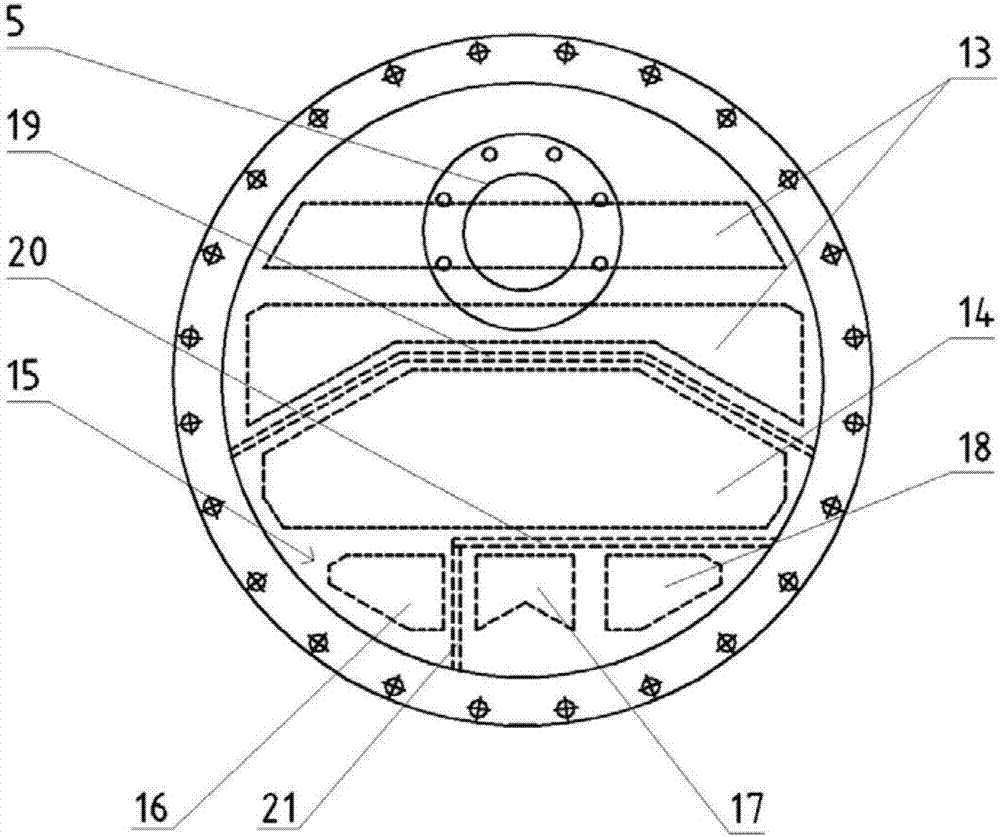

[0031] The interior of the shell 1 is provided with a plurality of axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com