Formula and preparation method of machine-made charcoal binding agent

A technology of binder and mechanism charcoal, which is used in pharmaceutical formulations, antidote, medical preparations containing active ingredients, etc. disadvantages and problems, significant social and environmental benefits, and the effect of inhibiting the release of toxic and odorous substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

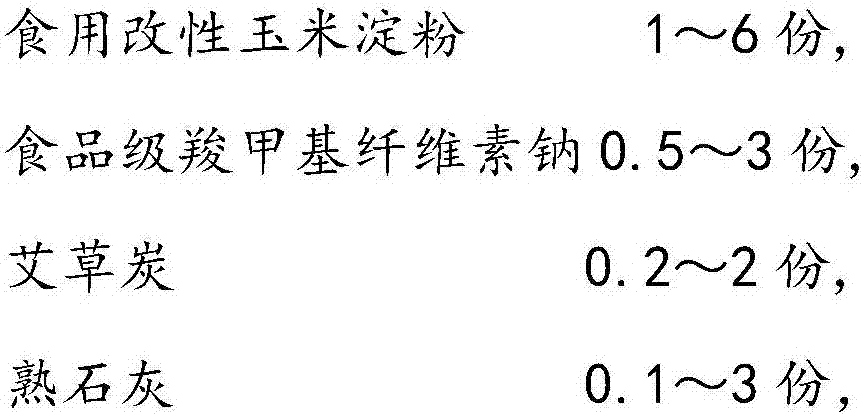

[0032] A method for preparing a machine-made charcoal binder. The formula of the machine-made charcoal binder includes two parts: solid and liquid, and the ingredients are combined according to the following weight fractions. The solid part: 1-6 parts of edible modified cornstarch; food-grade carboxymethyl 0.5-3 parts of sodium cellulose; 0.2-2 parts of wormwood charcoal; 0.1-3 parts of slaked lime, and the liquid part: 0.1-1% guar gum solution. Mix the solid part of the binder into the carbon powder according to the proportion, the addition ratio is 0.5-5% of the weight of the carbon powder, and then transport the material to the twin-shaft mixer for thorough mixing, then enter the wheel mill and add the liquid part in this section The binder is added in a proportion of 0.1-1%, and the rest is water, and the material and the binder are fully mixed evenly, and enter the molding machine through the conveying belt to be punched and formed into rods.

Embodiment 2

[0034] A machine-made carbon binder, the formula includes solid and liquid two parts, the combination of the following mass fractions:

[0035] Solid part:

[0036]

[0037] Liquid part:

[0038] 0.1% to 1% mass concentration guar gum solution.

[0039] The preparation of food-grade modified starch involves using a double-drum dryer, heating between the two drums to 40-200°C, and then inputting the starch emulsion between the two drums. The emulsion is immediately gelatinized and dried into a film on its surface. Scrape it off with a scraper and crush it to get the finished product.

[0040] The crushing equipment uses a double-roller mill, and the particle size is below 200 mesh. Because the raw corn starch powder is already below 200 mesh, it is easy to operate, avoid dust, and is easy to implement.

[0041] The water addition ratio of the starch emulsion is 30-80%, and the raw material is transported into the drum by scraper equipment.

[0042] The preparation proced...

Embodiment 3

[0046] Embodiment 3: A machine-made carbon binder, the particle size of sodium carboxymethyl cellulose is required to be below 200 mesh.

[0047] The particle size of slaked lime is below 200 mesh.

[0048] All raw materials are mixed according to the proportion, and mixed in a blender to form a finished product for use.

[0049] During the stirring process, the stirring speed is 5-30 rpm, and the stirring time is 5-10 minutes.

[0050] A guar gum solution with a mass concentration of 0.1-1% is prepared.

[0051] In the preparation process of the binder liquid part, add a certain amount of water to the mixing tank, turn on the power of the mixer at the same time, and then add the same proportion of guar gum and stir.

[0052] During the stirring process of the liquid part, the guar gum should be added slowly, the stirring time is 2 to 6 minutes, and the stirring speed should be such that the raw materials are not splashed out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com