A kind of preparation method of long carbon chain cyano acid

A technology of carbon chain cyano acid and cyano acid, which is applied in the direction of carboxylate preparation, carboxylate preparation, carboxylic acid amide preparation, etc., and can solve the problem that there is no process route for synthesizing nylon 9 and nylon 10

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

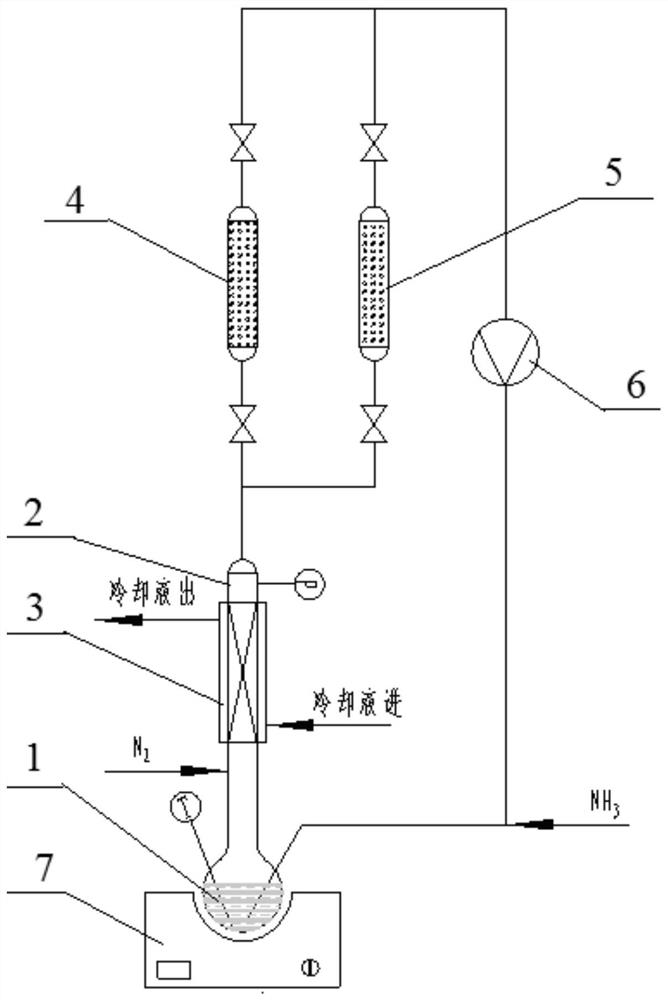

[0038] Put 2kg of azelaic acid and 60g of self-made composite catalyst into the reaction kettle, heat it to a molten state, close the valve, and after checking the air tightness, start the cooling liquid circulation pump of the packed tower (jacket temperature is 120-130°C), Ammonia gas was introduced slowly (mass flow meter control); then the gas circulation pump was started, nitrogen was automatically replenished during the process, and the pressure was maintained at 0.3 MPa.

[0039] The ammonia flow rate in the early stage is kept at 50cm 3 / h, heating to keep the temperature of the kettle at 165°C, and the pressure of the kettle at a constant 0.3MPa. After the reaction time is 2 hours, the temperature is gradually raised to 285°C. By adjusting the opening of the valve, the flow rate of ammonia is maintained at 20cm 3 / h, the pressure in the kettle was maintained at 0.2MPa, and the reaction time was 6 hours.

[0040] Stop the gas pump after the reaction is finished, take ...

Embodiment 2

[0042] Put 2kg of azelaic acid and 60g of self-made composite catalyst into the high-pressure reactor, heat it to a molten state, close the valve, and after checking the air tightness, start the cooling liquid circulation pump of the packed tower (jacket temperature is 120-130°C) , slowly feed ammonia gas (mass flow meter control); then start the gas circulation pump, automatically replenish nitrogen during the process, and maintain the pressure at 0.3MPa.

[0043] The ammonia flow rate in the early stage is kept at 50cm 3 / h, heating to keep the temperature of the kettle at 170°C, and the pressure of the kettle to be constant at 0.3MPa. After the reaction time is 2 hours, the temperature is gradually raised to 290°C, and the ammonia flow rate is maintained at 20cm by adjusting the opening of the valve. 3 / h, the pressure in the kettle was maintained at 0.2MPa, and the reaction time was 4.5 hours.

[0044] Stop the air pump after the reaction is finished, take out the crude p...

Embodiment 3

[0046]Put 2kg of sebacic acid and 60g of self-made composite catalyst into the high-pressure reactor, heat it to a molten state, close the valve, and after passing the air tightness inspection, start the cooling liquid circulation pump of the packed tower (jacket temperature is 120-130°C) , slowly feed ammonia gas (mass flow meter control); then start the gas circulation pump, automatically replenish nitrogen during the process, and maintain the pressure at 0.3MPa.

[0047] The ammonia flow rate in the early stage is kept at 50cm 3 / h, heating to keep the temperature of the kettle at 175°C, and the pressure of the kettle at a constant 0.2MPa. After the reaction time is 2 hours, the temperature is gradually raised to 295°C, and the ammonia flow rate is maintained at 20cm by adjusting the opening of the valve. 3 / h, the pressure in the kettle was maintained at 0.2MPa, and the reaction time was 5 hours.

[0048] Stop the air pump after the reaction is finished, take out the crud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com