Ridge line shaping and sharpening method of covering part and shaping mold thereof

A technology for shaping molds and covering parts, applied in vehicle parts, forming tools, manufacturing tools, etc., can solve problems such as failure to produce sharp edge forming force, unqualified outer covering products, failure to meet pressure requirements, etc. Thinning of edges and corners, ensuring the accuracy of pressing and preventing collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

[0030] like Figure 1 to Figure 7 As shown, a method for shaping and sharpening the ridge line of the covering part is carried out according to the following procedures:

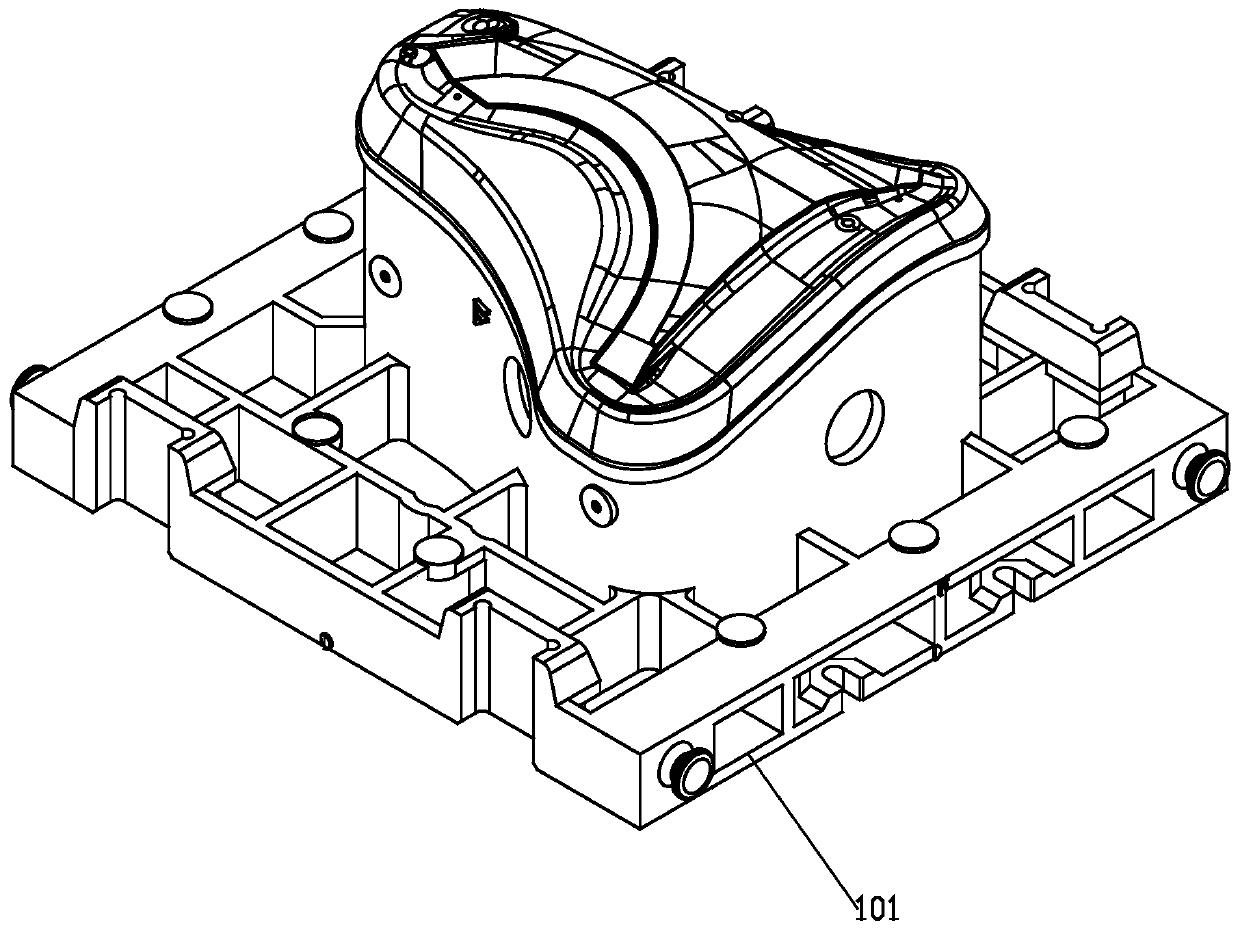

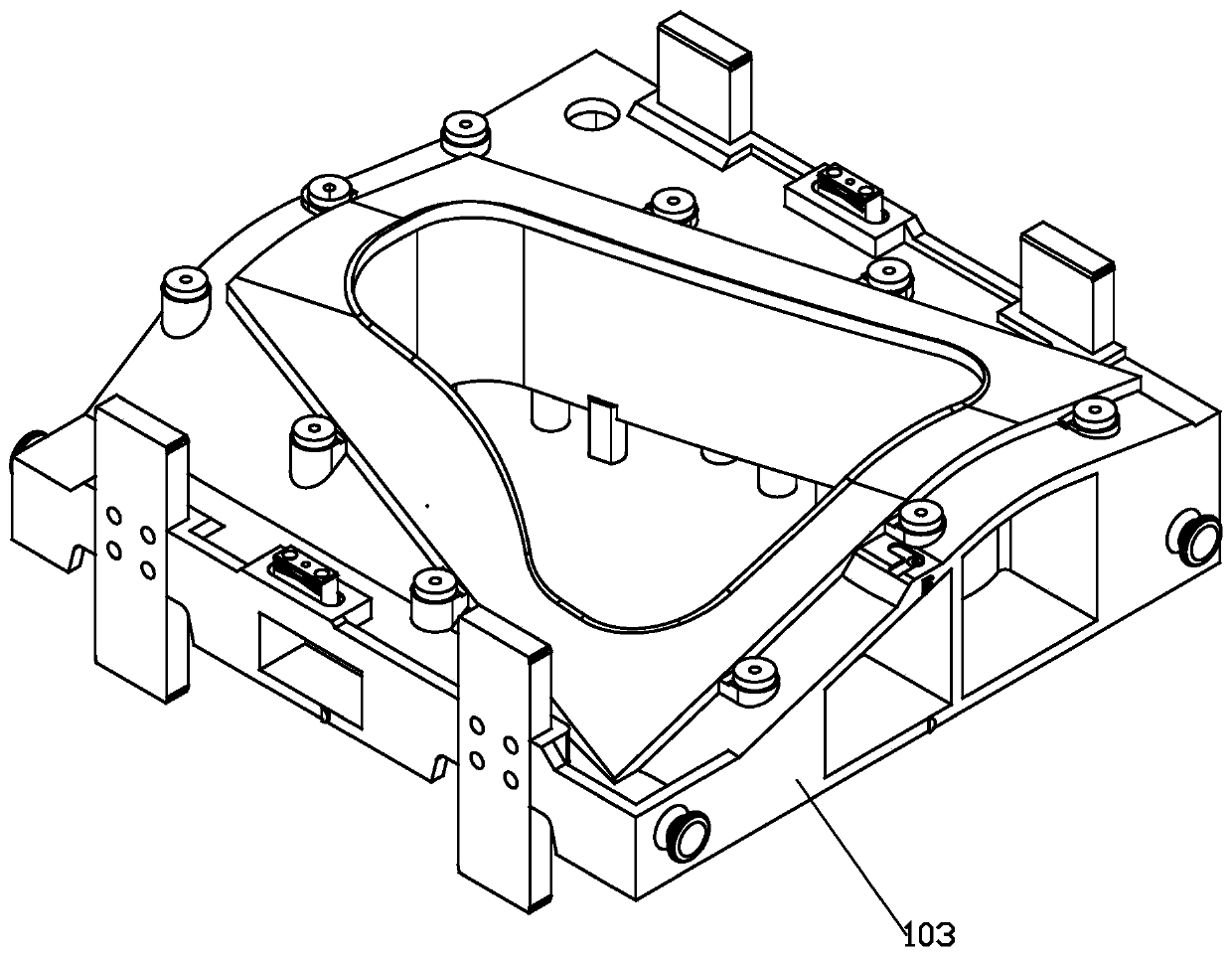

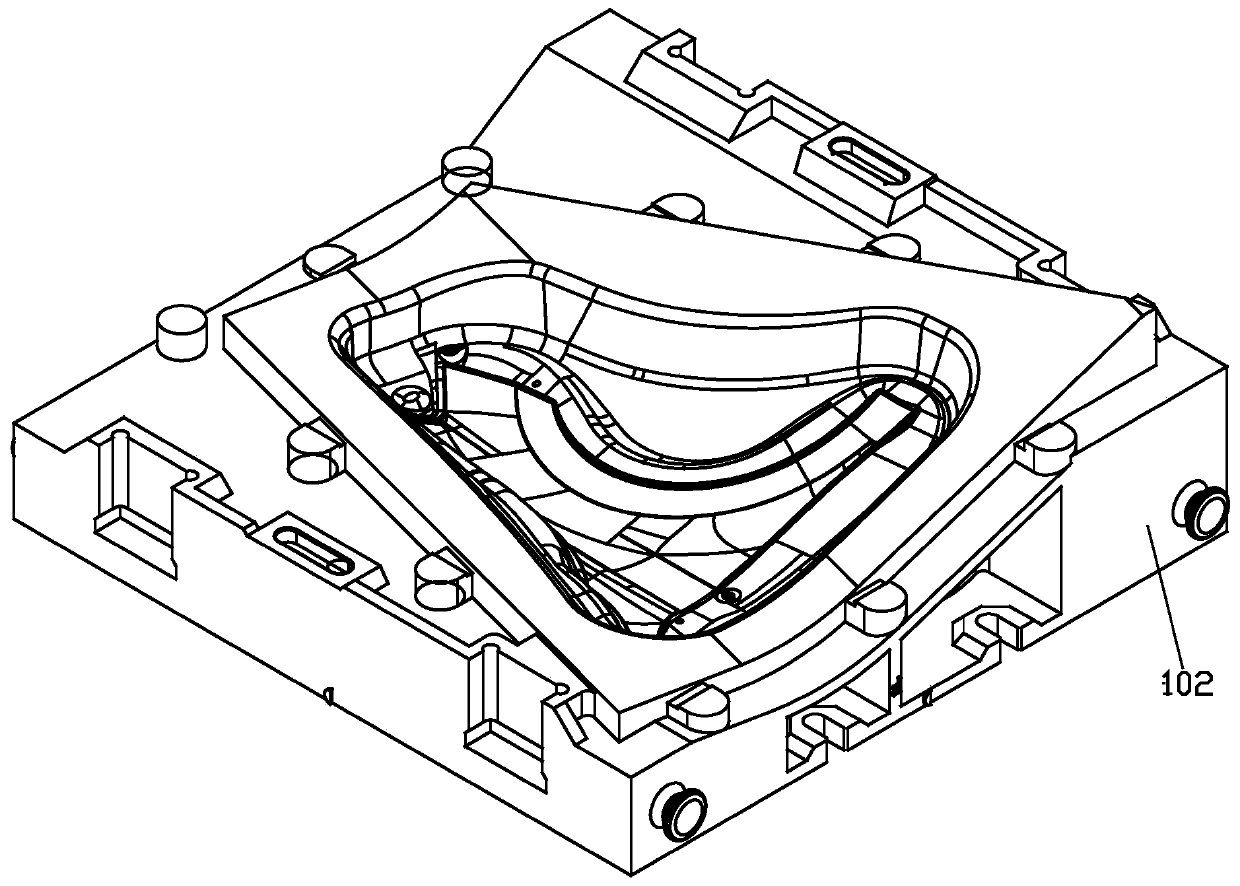

[0031] (1) Drawing: Utilize drawing die 1 tool to carry out stamping and drawing to cover piece, cut blank, and described drawing die 1 comprises drawing punch 101, drawing die 102 and is sleeved on drawing punch 101 The blank holder 103. During the drawing process, the fillet at the ridge line of the drawing punch 101 is the same as that of the original product, and no sharpening treatment is performed (different from using the ridge line at the 101 ridge line of the drawing punch to make the ridge line of the cover part smaller sharpening process), the purpose of which is to reduce the slippage of the ridge line a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com