Novel parameter setting integrated system of twenty-high rolling mill control technology

A rolling mill control and integrated system technology, applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

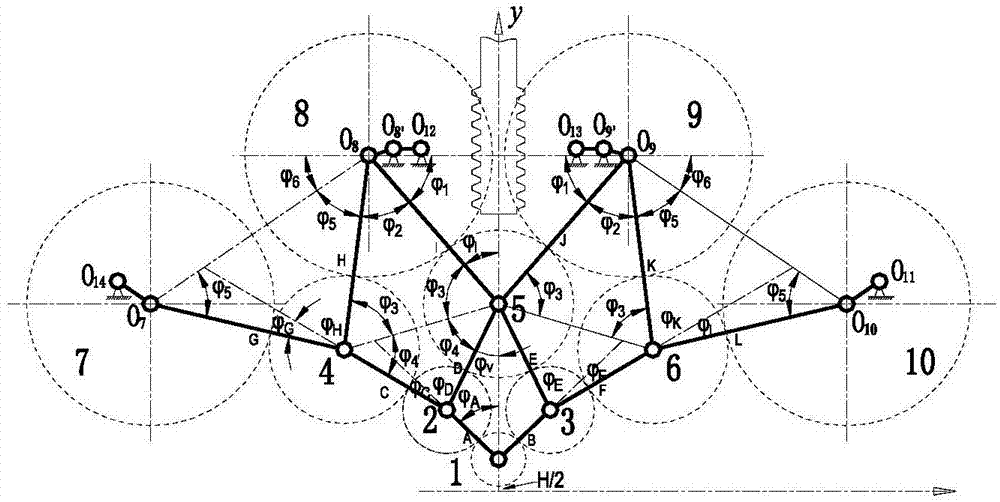

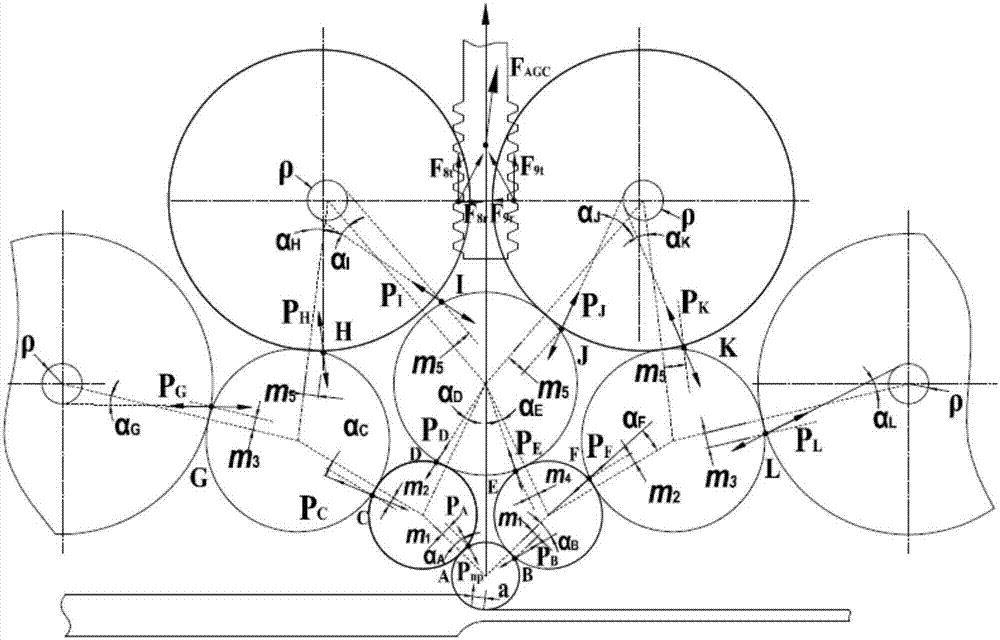

[0080] like Figure 1 to Figure 7 As shown in the figure, a new integrated system for parameter formulation of 20-high rolling mill control process includes a rolling schedule optimization formulation module, an elastic roll diameter matching roll module, a force energy parameter calculation module and a rolling mill roll system,

[0081] The incoming material thickness, finished product thickness, strip width, maximum rolling force, maximum reduction ratio and work roll diameter are input into the rolling schedule optimization and formulation module, and the rolling passes, total reduction ratio, and pressure of each pass are output. Down rate, rolling force, front and rear tension, rolling speed, rolling power and rolling pass exit thickness;

[0082] After the roll diameter compensation eccentric distance, the reduction adjustment eccentric distance and the rolling pass exit thickness are input into the elastic roll diameter matching roll module, the output work roll diamet...

Embodiment 2

[0147] like figure 1 As shown in the figure, a new integrated system for parameter formulation of 20-high mill control process includes a rolling schedule optimization formulation module a, an elastic roll diameter matching roll module b and a force energy parameter calculation module c. Data is exchanged between the rolling schedule optimization and formulation module a, the elastic roll matching module b and the force energy parameter calculation module c.

[0148] like figure 2 As shown in the figure, the rolling mill roll system of the integrated system for setting parameters for the control process of the new twenty-high rolling mill includes: work roll 1, a first intermediate roll group, a second intermediate roll group, and a backup roll group, and the first intermediate roll group It includes an intermediate roll I2 and an intermediate roll II3 symmetrically arranged above the work roll 1, the second intermediate roll group is arranged above the first intermediate ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com