Feeding-controllable system for screening before flour grinding of wheat

A controllable and unloading technology, which is applied in the direction of sieving, grain grinding, magnetic separation, etc., can solve the problems of poor screening effect, complex structure, and insufficient cleanliness, so as to reduce maintenance costs and labor intensity, Extended service life and beneficial cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

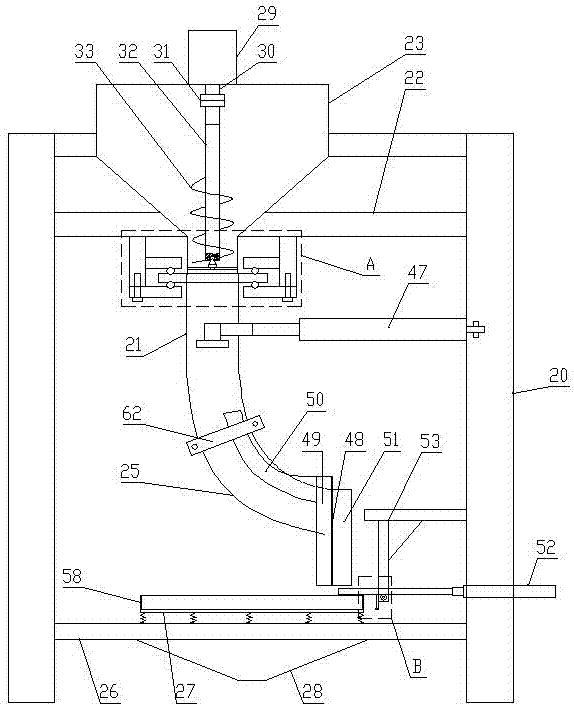

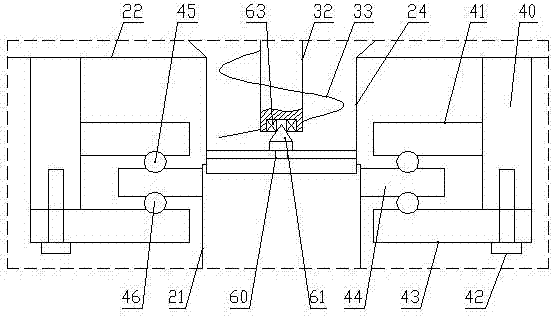

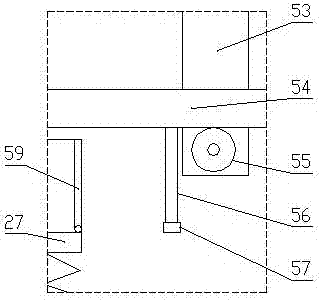

[0032] Such as Figure 1-Figure 8 As shown, the feeding controllable type screening system before wheat flour milling of the present invention comprises a support 20 and a feeding pipe, the upper part of the support 20 is horizontally provided with an upper frame 22, and the upper frame 22 is provided with a storage tank 23, the storage tank The lower part of 23 is a conical structure that is thicker at the top and thinner at the bottom. The lower end of the storage tank 23 is connected with a guide tube 24. The bracket 20 is fixedly provided with a support hanging structure located outside the guide tube 24. The upper end of the feeding tube is rotatably connected to the support. In the hanging structure, the lower end of the guide pipe 24 is inserted in the feeding pipe, and the feeding pipe is composed of a straight pipe section 21 arranged vertically on the upper part and a bent pipe section 25 at the lower part, and a swing drive connected to the straight pipe section 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com