Unpowered automatic impurity-removing device for river sand mining equipment

A mining equipment and power technology, which is applied in the field of unpowered automatic impurity removal devices, can solve the problems of manpower and material resources, affecting work efficiency, small size, etc., and achieve the effect of facilitating the recovery of iron impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

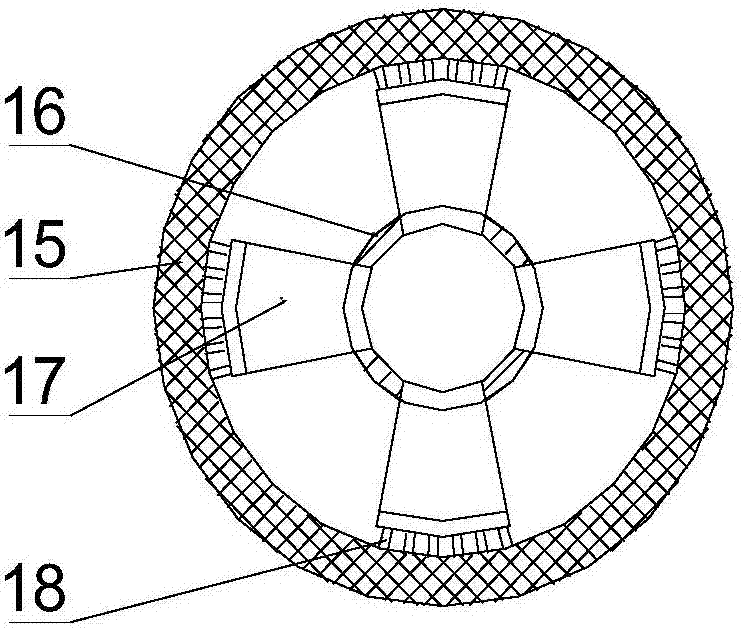

[0017] see Figure 1-3 , an unpowered automatic impurity removal device for river sand mining equipment, comprising a first impurity removal box 1, a second impurity removal box 12, a conical net cover 3, an inclined material guide plate 2, an iron impurity recovery device, Inner cylinder 14, arc-shaped net 15, rotating cylinder 14, propeller impeller 20, fixed cylinder 21, and pressure relief valve 23. The upper side of the first miscellaneous removal box 1 is fixedly connected with an inclined shape that is low on the left and high on the right. The inclined material guide plate 2, the upper side of the inclined material guide plate 2 is provided with a conical net cover 3 with a narrow upper part and a wider bottom, the lower part of the conical net cover 3 is fixed through the inclined material guide plate 2, and the first miscellaneous removal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com