Graphene conductive paste special for lithium battery and preparation method of graphene conductive paste

A technology of graphene and conductive paste, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of poor conductivity, achieve low cost, enhance conductivity and rate charge and discharge performance, and reduce investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

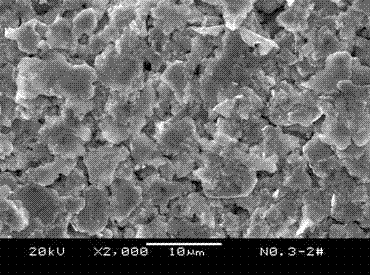

Image

Examples

Embodiment 1

[0034] (1) Mix 20 parts by weight of expanded graphite and 1 part by weight of sodium polyacrylate as a dispersant to form an abrasive, put it into a disc grinder for grinding, and then disperse ultrasonically for 20 minutes at a frequency of 40-60KHz to obtain a uniform dispersion mixture A;

[0035](2) Add 1 part by weight of modifier stearic acid to mixture A, and continue grinding in a grinder for 30 minutes to obtain mixture B;

[0036] (3) Add 2 parts by weight of a cross-linking agent to the mixture B, and continue grinding in the grinder for 30 minutes, while controlling the pressure at 2 MPa and maintaining the temperature at 120°C for 1 hour, so that the graphene flakes are cross-linked into a network structure, and the mixture C is obtained ; The cross-linking agent is prepared from acrylic acid and sulfur at a mass ratio of 1:0.5.

[0037] (4) Mix the mixture C with 70 parts by weight of the solvent tetrahydrofuran evenly, and disperse in a homogenizer for 30 minu...

Embodiment 2

[0041] (1) Mix 15 parts by weight of graphite flakes and 1 part by weight of polyvinylpyrrolidone as a dispersant to form an abrasive, put it into a grinder for grinding, and then ultrasonically disperse at a frequency of 60KHz for 40 minutes to obtain a uniformly dispersed mixture A;

[0042] (2) Add 2 parts by weight of modifier titanate coupling agent to mixture A, and continue to grind in the grinder for 60 minutes to obtain mixture B;

[0043] (3) Add 1 part by weight of cross-linking agent to the mixture B, continue to grind in the grinder for 30 minutes, while controlling the pressure at 3 MPa, and maintaining the temperature at 125°C for 2 hours, so that the graphene flakes are cross-linked into a network structure, and the mixture is obtained C; The crosslinking agent is prepared from N-methylolacrylamide and sulfur at a mass ratio of 1:0.8.

[0044] (4) Mix mixture C and 80 parts by weight of solvent N-methylpyrrolidone evenly, and disperse in a homogenizer for 40 mi...

Embodiment 3

[0047] (1) Mix 10 parts by weight of conductive graphite and 2 parts by weight of dispersant sodium carboxymethyl cellulose into a grinding material, put it into a gear grinder for grinding, and then disperse it ultrasonically for 25 minutes at a frequency of 40KHz to obtain a uniformly dispersed mixture A ;

[0048] (2) Add 3 parts by weight of modifier aluminate coupling agent to mixture A, and continue grinding in the grinder for 40 minutes to obtain mixture B;

[0049] (3) Add 2 parts by weight of a cross-linking agent to the mixture B, and continue grinding in the grinder for 30 minutes, while controlling the pressure at 2 MPa and maintaining the temperature at 120°C for 1 hour, so that the graphene flakes are cross-linked into a network structure, and the mixture C is obtained ; The cross-linking agent is prepared with divinylbenzene and sulfur at a mass ratio of 1:0.5.

[0050] (4) Mix mixture C with 75 parts by weight of solvent N-octylpyrrolidone evenly, and disperse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com